- Tradeindia

- Box Making Machines

- Corrugated Box Machine

Corrugated Box Machine

(279 products)Digital Corrugated Box Compression Testing Machine - Color: Combination Of D.A. Grey & White Colour

Price Trend: 175000.00 - 260000.00 INR/Piece

MOQ1 Piece/Pieces

General UseFor corrugated box compression testing

MaterialStainless Steel Alloy

ComputerizedYes

AutomaticYes

Touch ScreenYes

Control SystemPLC Control

Eie Instruments Private Limited

Ahmedabad

Trusted Seller

Trusted Seller15 Years

Super Seller

Super SellerCorrugated Box Making Machine Box Size: Custom

Price: 575000.00 INR/Set

MOQ1 Set/Sets

ColorAs per Customer Choice

Product TypeOblique Type

General UseTo Make Carton box

MaterialCardboard

Box sizeCustom

FunctionTo make Carton Box

Senior Paper Packing Machinery Mfg. Co.

Amritsar

Trusted Seller

Trusted Seller20 Years

Super Seller

Super SellerIndustrial Corrugated Box - Finish: Polished

Price: 50 INR/Piece

MOQ25000 Piece/Pieces

Printing TypeEmbossing

Paper TypeKraft Paper

FinishPolished

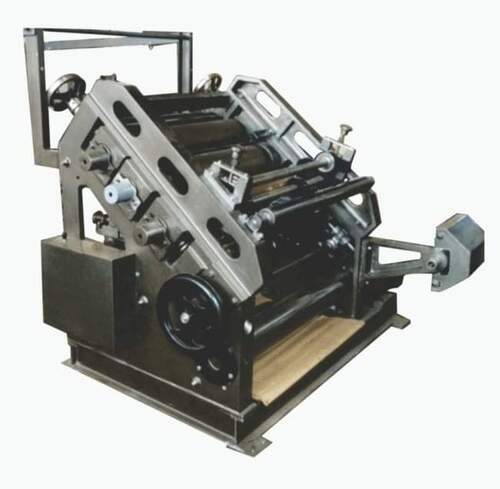

Semi-Automatic Corrugated Box Machine

Price: 773000.00 INR/Unit

MOQ1 Unit/Units

ColorGreen

Product TypeCorrugated Box Machine

General UseIndustrial

MaterialOther

Automatic GradeSemi-Automatic

ComputerizedNo

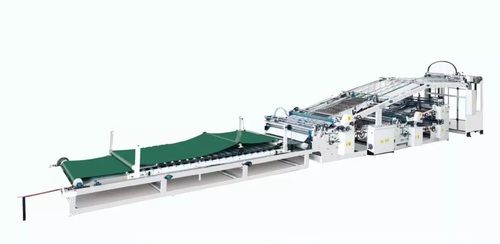

Automatic Machine For Erecting Corrugated Vegetable And Fruit Box - Dimension (L*W*H): 3500*1850*2800Mm (L*W*H) Millimeter (Mm)

Price: 20000 USD ($)/Unit

MOQ1 Unit/Units

Product TypeAutomatic Machine For Erecting Corrugated Vegetable And Fruit Box

Weight (kg)1500 Kilograms (kg)

ComputerizedNo

AutomaticYes

Drive TypeElectric

Dimension (L*W*H)3500*1850*2800mm (L*W*H) Millimeter (mm)

Ruian Good Machinery Co. Ltd

Wenzhou

Trusted Seller

Trusted Seller3 Years

Premium Seller

Premium SellerCorrugated Box Airpack Packing Stand Up Pouch

Price: 425 INR/Kilograms

MOQ50 Kilograms/Kilograms,

Product TypeAir Bag

MaterialPlastic

Bag TypeStand Up Pouch

StyleSingle String

Sealing & HandlePatch Handle

Size25-80

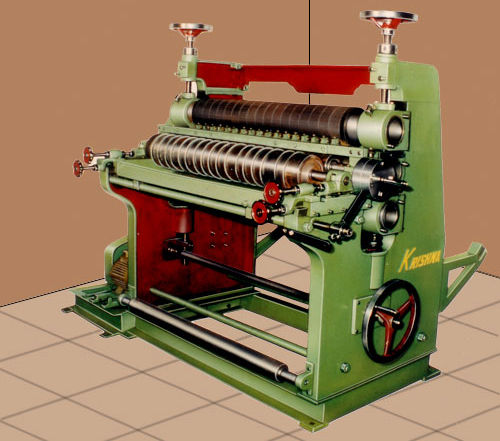

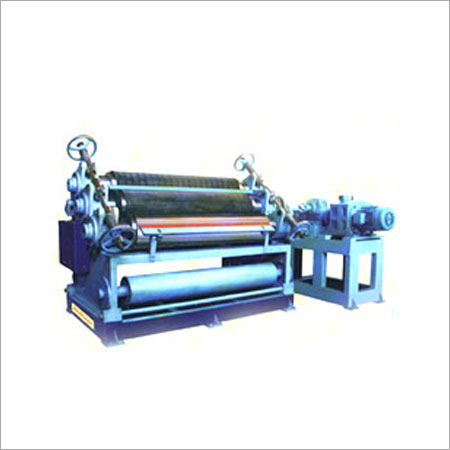

Green Vertical Type Paper Corrugating Box Machine

Price: 850000 INR/Unit

MOQ1 Unit/Units

ColorGreen

Product TypeVertical Type Paper Corrugating Box Machine

AutomaticYes

Voltage220-440 Volt (v)

Shree Krishna Engineering Works

Surat

Trusted Seller

Trusted Seller3 Years

Premium Seller

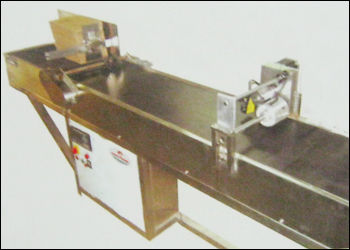

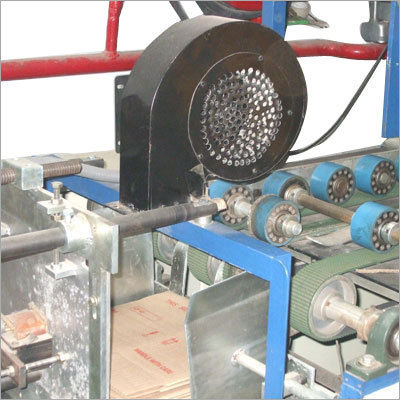

Premium SellerCorrugated Box Coding Machine

Product DescriptionWith firm dedication to quality, our organization is manufacturing and supplying a best grade array of Corrugated Box Coding Machine. These machines are appreciated by large number of clients due to high quality and durability. We offer these collection at market attractive selling price ranges

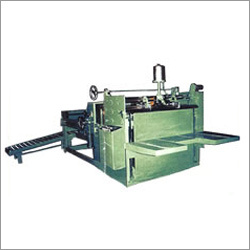

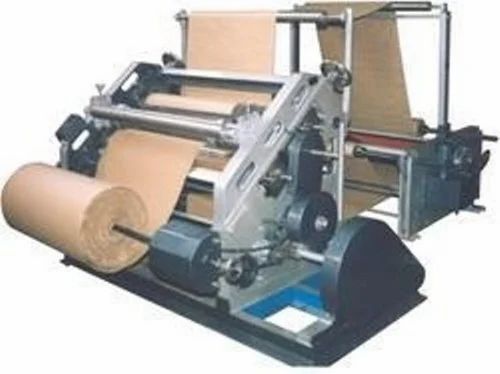

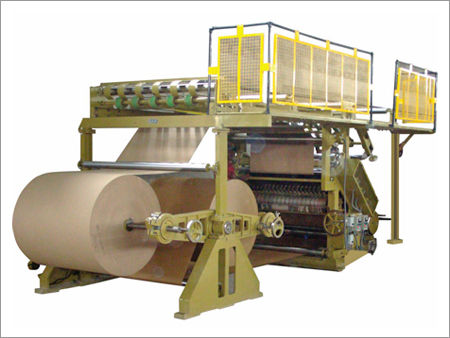

Corrugated Box Making Machine

Product DescriptionWe are providing Corrugated Box Making Machine to our esteemed clients. This is well proven the fingerless single face technology. In a new and exciting way with a speed of upto 300 meters/P.M. The Model MD-94 assures a smooth production of quality board. Switch from routine corrugating to higher pe

Micro Engineers (india)

Vasai

Trusted Seller

Trusted Seller10 Years

Premium Seller

Premium SellerBlue & Gray 5 Ply Fully Automatic Corrugated Board Production Line

Price Trend: 16000000.00 - 22500000.00 INR/Unit

MOQ1 Unit/Units

Product Type5 Ply Fully Automatic Corrugated Board Production Line

General UseIndustrial

MaterialPlywood

TypeCorrugated Box Making Machine

ComputerizedNo

AutomaticYes

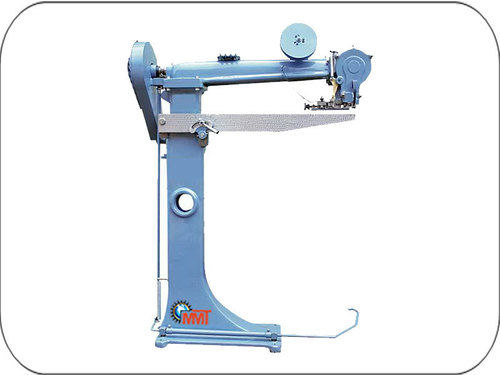

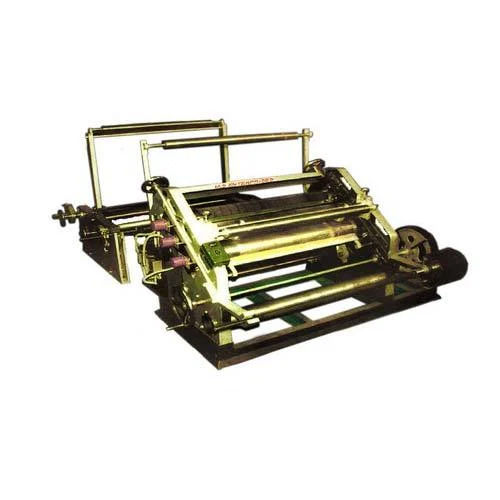

Natraj Box Making Machine

Product DescriptionWe have emerged as the foremost Exporter, Importer, Manufacturer, Distributor, Supplier, Trading Company of Natraj Box Making Machine in Delhi, India. This machine is widely used for the making of a corrugated box. To ensure its sturdiness at our clients' end, our quality examiners stringently check

Corrugated Box Lock Bottom Pasting Machine - Feature: Automatic Feeder

Price: 600000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

ComputerizedNo

AutomaticYes

Drive TypeElectric

Power200-240 Volt (v)

Warranty5 Years

Top Rated Products

Digital Corrugated Box Compression Testing Machine - Color: Combination Of D.A. Grey & White Colour

Eie Instruments Private Limited

FAQs Related to Corrugated Box Machine

Who are the top corrugated box machine manufacturers in India?

- Natraj Industries

- Monu Graphics

- Associated Industrial Corporation

- Senior Paper Packing Machinery Mfg. Co.

- Sheth Printograph Pvt. Ltd.

- S. K. Package Machine

- Precision Machines & Automation

- Eie Instruments Private Limited

- Micro Engineers (india)

- Cangzhou Kenuo International Co., Ltd.

Which cities have the largest number of corrugated box machine suppliers?

- Chennai

- Mumbai

- Pune

- Kolkata

- Delhi

- Hyderabad

- Bengaluru

- Jaipur

- Faridabad

- Ahmedabad

- Vapi

- Surat

- Ludhiana

- Ballabgarh

- Thane

- Gurugram

- Amritsar

- Rajkot

- Indore

- Coimbatore

What is the price range for corrugated box machine offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| Harman Machine Tools | INR | Corrugated Box Machine | 550000 |

| Millenium Packaging Solutions | INR | Corrugated Box Packaging Machine | 600000 |

| SUKHMANI INDUSTRIES | INR | Corrugated Box Machine | 650000 |

| SAMRAT ENGINEERING WORKS | INR | Corrugated Box Making Machine | 760000 |

| NISHARG ENGINEERING WORKS | INR | Corrugated Box Lock Bottom Pasting Machine | 600000 |

| Atulya Machines Private Limited | INR | Corrugated Box Machine | 3000000 |

| Mars Automotive | INR | Corrugated Box Baling Machine | 325000 |

| Hardev industries | INR | Corrugated/Carton Box Making Machine | 600000 |

| VIJAY MARUTI PRINT PACK MACHINERIES | INR | Corrugated Box Pasting Machine | 2500000 |

How many trusted sellers are available for corrugated box machine?

- EIE INSTRUMENTS PRIVATE LIMITED

- SENIOR PAPER PACKING MACHINERY MFG. CO.

- PANCHAM PACKAGING

- MONU GRAPHICS

- Ruian Good Machinery Co. Ltd

- AIR PACK

- SHREE KRISHNA ENGINEERING WORKS

- MICRO ENGINEERS (INDIA)

- NISHARG ENGINEERING WORKS

- MAYSTER ENGINEERING PRIVATE LIMITED

- MANO INDUSTRIAL MACHINE TOOLS

- GLOBAL ENTERPRISES

- SUKHMANI INDUSTRIES

- Mars Automotive

- M. S. Enterprises

- NATRAJ INDUSTRIES

What is the minimum order quantity for corrugated box machine?

Do listed companies have registration & certifications?

- EIE INSTRUMENTS PRIVATE LIMITED

- SENIOR PAPER PACKING MACHINERY MFG. CO.

- MONU GRAPHICS

- GARUDA ENGINEERS

- S. K. PACKAGE MACHINE

- ASSOCIATED INDUSTRIAL CORPORATION

- NATRAJ INDUSTRIES

- PRECISION MACHINES & AUTOMATION

What is the get latest price feature?

What types of payment methods are accepted by the corrugated box machine suppliers?

Hydraulic Double Profile Corrugated Machine Grade: Semi-Automatic

Price: 2400000 INR/Unit

MOQ5 Unit/Units

GradeSemi-Automatic

MaterialStainless Steel

ComputerizedNo

Control SystemFrequency Speed Control

WarrantyYes

Silver 3 Ply Automatic Corrugated Box Machine

MOQ1 Unit/Units

MaterialSteel

Operating TypeAutomatic

Usage LevelIndustrial Level

Power SourceElectric

ColorSilver

Mayster Engineering Private Limited

Noida

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerCorrugated Box Machine - Superior Quality, Corrosion Resistant Design | Robust Durability, Dimensional Accuracy

MaterialSteel

DimensionsNA

Power3.7 kW

Voltage415 V

Frequency50 Hz

Weight1000 kg

Mano Industrial Machine Tools

Chennai

Trusted Seller

Trusted Seller9 Years

Premium Seller

Premium SellerSingle Face Corrugated Machine - Color: Yellow

MOQ1 Piece/Pieces

Product TypeSingle Face Corrugated Machine

General UseIndustrial

ComputerizedNo

AutomaticYes

Drive TypeElectric

Voltage220 Volt (v)

Semi Automatic Corrugated Box Making Machine - Metallic Finish, User-Friendly, Prolonged Service Life | Smooth Functioning, Timely Delivery, Quality Tested

Product TypeCorrugated Box Making Machine

General UseTo make corrugated box

AutomaticYes

ColorMetallic

Global Enterprises

Delhi

Trusted Seller

Trusted Seller3 Years

Premium Seller

Premium SellerCorrugated Box Making Machine

Price: 900000 INR/Unit

MOQ1 Unit/Units

Product TypeCorrugated Box Making Machine

General UseFor Industrial

TypeCorrugated Box Making Machine

AutomaticYes

Drive TypeElectric

Box Corrugation Machine Capacity: 3-5 Ton/Day Ton/Day

Price: 900000 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeBox Corrugation Machine

General UseIndustrial

MaterialMild Steel, Other

Capacity3-5 ton/day Ton/day

AutomaticNo

Corrugated Machine - Profile Model Series WLRF25-248-992, WLRF50-250-1000, Custom Design Options Available

Price: 1800000 INR/Unit

MOQ1 Unit/Units

Product DescriptionOur company has hundreds of profile models for this series Corrugated Machine, such as WLRF25-248-992, WLRF50-250-1000,WLRF18-76-988, and etc. We can design different kinds of profile and fittings for machine, as per customers' requirements.\015\012\015\012Corrugated Machine Working Flow: Uncoiling

5 Layer Corrugated Cardboard Production Line Carton Machine Application: Industrial

MOQ1 Unit/Units

ApplicationIndustrial

ConditionNew

ColorWhite

TypeLine Carton Machine

Industrial Corrugated Box Baling Machine

Price: 325000 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeCorrugated Box Baling Machine

General UseIndustrial use

ComputerizedNo

FeaturePLC Controll

Mixed Corrugated Fin Forming, Folding Machine For Transformer Corrugated Tank Manufacturing

MOQ1 Unit/Units

Product TypeCorrugated Fin Forming, Folding Machine

General UseBox Making and Folding Machine

TypeBox Folding Machine, Corrugated Box Making Machine

ComputerizedNo

AutomaticNo

Drive TypeElectric

Corrugated Box Machine - Operating Type: Automatic

Price: 2200000 INR/Unit

MOQ1 Unit/Units

Product TypeOther, Corrugated Box Machine

Power SourceElectricity

Operating TypeAutomatic

Surface TreatmentCoated

Warranty1 Year

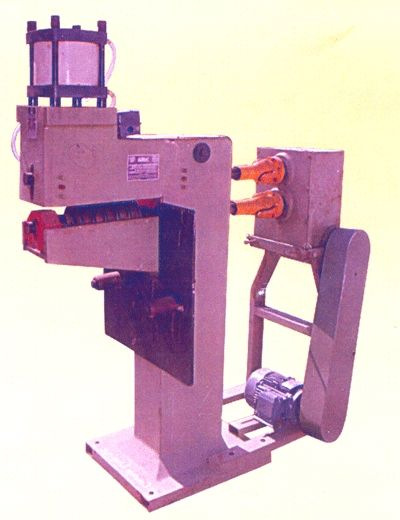

Oblique Corrugated Box Machines

Product DescriptionBeing a customer centric organization, we are involved in manufacturing, exporting and supplying a supreme quality range of Oblique Corrugated Box Machines in Faridabad, Haryana, India. These machines are manufactured by utilizing supreme quality raw materials and innovative technology. Furthermore

Corrugated Box Machine - High-Quality Raw Material, Advanced Technology | Timely Delivery Assurance

MOQ1 Unit

Payment TermsTelegraphic Transfer (T/T), Others, Letter of Credit (L/C)

Corrugated Box Pasting Machine - Heavy-Duty Steel Construction, High-Performance Adhesive Application System

Product DescriptionCorrugated Box Pasting Machine

Corrugated Box Making Machine - High Speed Performance, Rust Resistant Design - Precision Engineering for Efficient Production

Product DescriptionBacked with a team of experienced professionals, we are engaged in exporting, manufacturing and supplying of corrugated box making machine in Noida, Uttar Pradesh, India. This Corrugated Box Making Machine is widely praised by our clients for its high efficiency and precise design. \015\012\015\012F

Latest from Corrugated Box Machine

Cardboard Corrugated Box Machine

By:

Sukhmani Industries

3 Ply Automatic Corrugated Box Machine

By:

Mayster Engineering Private Limited

Paper Corrugated Box Machine

By:

Vaishno Mechanical Works

Corrugation Box Machine 2

By:

Amritsar Wood & Machinery Works

Corrugated Box Machine

By:

Ravi Engineering Works

Mild Steel Corrugated Box Machine

By:

Janta Printing & Packaging Machines

Explore More Cities

Ready To Ship Corrugated Box Machine

Learn About The Corrugated Box Machines Key Features, Uses etc.

Corrugated boxes are used to ship different kinds of items in almost every industry whether you talk about food, automotive, chemical, or pharma. They have multiple layers of cardboard to increase the strength and durability for keeping the products safe during transportation. Corrugated box machines are used to create these boxes at high speed with accuracy. It uses a cardboard sheet to start the manufacturing process and a series of rollers move the cardboard forward to create boxes. Let’s read in detail how these boxes help make shipping products safer.

Origins and Development of Corrugated Boxes

- It all started in England in 1856, when the first corrugated paper got permission for commercial use.

- The first corrugated box was registered by Albert Jones in 1871 in the United States.

- Three years later a person named G. Smyth created the first machine to produce corrugated boxes in large quantities.

- Until the 1900s, the technology to create corrugated boxes got better and better to use for shipping products safely. Moreover, corrugated cardboard was even used for insulation in construction projects.

Key Technological Milestones in Corrugated Box Machinery

Corrugated box machines have improved a lot with new technology and features:

-

Smart Production

Corrugated box machines now have AI features that can automatically detect errors and monitor performance in real-time. Moreover, the system can make decisions on its own to adjust to the new settings.

-

Computerized Printing

With the help of computer printing the machine can directly print designs onto the boxes. This technology helped the companies to make custom packaging materials.

-

Automatic Machines

Automatic corrugated box machines were developed for making boxes in large quantities. Many industries require these boxes to ship their products safely. Hence, the companies hire automatic machines for producing and delivering bulk orders on time.

-

Sensors and Chips

These machines now have advanced sensors and chips for monitoring the movement of goods and sensing the temperature in storage conditions to maintain the product's quality.

-

Adding Bioplastic

The bioplastic is added to the material used to produce corrugated boxes to make them more durable to hold heavy products. Shipping delicate products becomes very easy with this process.

-

Eco-Friendly Materials

There are new eco-friendly materials introduced for making corrugated boxes. With this, a business can still practice sustainable operations and maintain the same quality of their products. These new materials allow businesses to practice sustainable operations and follow regulatory standards.

How Corrugated Box Machines Revolutionized Packaging

-

Bulk Production For Higher Demand

With automatic corrugated machines, the companies are able to complete bulk orders in the promised time. The operators can set instructions for the machine and just have to monitor the complete process for smooth operations. Also, they can input different sizes and shapes into the machine to manufacture custom boxes for shipping unique items. Automatic corrugators also help companies cut expenses with fewer labor costs and the waste of cardboard.

-

Maintains Quality Throughout the Process

With automatic corrugators, the chances of human errors are now gone. These machines only require a few instructions and the size or shape of the boxes required to produce. The rest of the work will be carried out by the machines very easily. The machine offers high accuracy in cutting the exact shapes of the cardboard boxes with quality. Corrugated box machines maintain high quality throughout the batch and every box offers high durability.

-

Eco-Friendly Operations

Automatic corrugated machines have incredible speed to produce shipping boxes. That’s why they contribute towards eco-friendly business practices by producing boxes on demand. Now, the company won’t have to stock the boxes to ship when the order comes. They can fulfill the demand as the order arrives and produce corrugated boxes faster to deliver on time. This minimizes the wastage of resources and promotes sustainable business.

Core Components and Their Functions

- Mill Roll Stand: it holds the paper roll and feeds the machine to produce boxes.

- Single Facer: this component makes waves to paper to make it strong.

- Preheated: it is required for heating the paper so it goes into the machine better.

- Gluing Unit: this part puts the glue on the paper so that they stick multiple layers together.

- Double Facer: it is used to add another layer on top of the glued layers for more durability.

- Cutter: it is responsible for cutting the cardboard into even pieces to produce equal-sized boxes.

- Slitter and Scorer: This component draws the lines for the machine to fold the cardboard accurately.

- Stacker: After the cardboard pieces are cut the stacker carefully collects them.

- Die Cutter: the die cutting machine cuts out the required shapes from the cardboard.

- Printer: it is used for printing special designs and logos on the cardboard for brands.

- Folder Gluer: finally the folder gluer is used to fold the cardboard and glue it to make a box.

Industries That Use Corrugated Box Machines

-

E-commerce

The E-commerce industry uses a lot of corrugated boxes to keep their products safe while shipping. Actually, they use two types of packaging to avoid any sort of damage to the product. First is interior packaging and the second is exterior packaging. The corrugated boxes are used as exterior packaging for shipping products all over the country. Many different types of boxes are used in e-commerce that have different shapes and sizes to have a perfect fit for products.

-

Marketing and Printing

Now that the printing industry has so many ways to decorate corrugated boxes they serve as promotional tools for many brands. Marketing professionals are using these boxes to advertise their products and services. High-quality designs on the boxes make them highly attractive and appealing. They capture the eyes of everyone when delivered to houses.

-

Food & Beverage

The Food & Beverage industry is using corrugated boxes in a large quantity. They use these boxes for both shipping their products and promoting the brand name. As these boxes are durable they can carry heavy food and beverage products. Moreover, the companies get their brand’s logo and design printed on the boxes for advertisement.

-

Supply and Stationery

Stationery products like paper are also shipped using corrugated boxes as they can easily be damaged without protection. These boxes keep the items secure with their durability that comes from multiple layers of cardboard. Moreover, these boxes are used for displaying the stationery products so that it does not get damaged in the process.

-

Textile and Luxury Goods

Online purchased textile products are shipped in corrugated boxes to prevent any kind of damage. Customers expect their products to be in the best condition when they order online. Companies make sure they receive it with double protection using both interior and exterior packaging. Moreover, the companies also print their brand logo and design for free advertisement as they know that people do unboxing videos on different platforms.

-

Electronics

Corrugated boxes are created with multiple layers of cardboard and they provide excellent protection to the packages. The electronic industry gets the most benefits from their durability as they ship every product in corrugated boxes. Whether you have purchased the product online or offline the company only uses these boxes for packaging and shipping. For extra protection layers, they add custom-shaped thermocol around the product and then pack it in the boxes.

-

Healthcare

The healthcare industry also uses corrugated boxes for keeping their medical instruments and devices safe. These equipment are very delicate so even a little damage can disturb their functioning. Corrugated boxes are made from multiple layers of cardboard for protection of the product inside. Moreover, the companies use different shapes of thermocol for packaging the devices inside these boxes safely.

-

Batteries and hazardous materials

The companies have followed strict guidelines and regulations when they have to transport batteries and different types of hazardous materials. These types of products can be damaged very easily and temperature changes can affect their working efficiency. For this problem, the companies use corrugated boxes to pack these items and keep them safe from damage because of falling, vibrations, and temperature changes.

-

Logistics and Shipping

Corrugated boxes are used in large quantities in fields like logistics and shipping for the safety of the products. When you place an order online it is wrapped with multiple layers of protection including bubble wrap, interior packaging, and exterior packaging. Out of these, the most durable are exterior packages which are corrugated boxes that protect the products from any kind of damage.

-

Military

Shipping military items is a difficult job that requires extra paperwork and following a set of regulations. Some of the items that the military uses are very delicate and require extra care. To solve this problem multiple layers of protection are used while shipping them which also includes using corrugated boxes. These boxes keep the items safe from damage, temperature changes, humidity, and more problems.

Major Advantages of Corrugated Box Machines

-

Save Expenses

With automatic corrugated box machines, the making of corrugated boxes becomes less expensive. The company doesn’t require manual labor for completing the job and the machine can work automatically from feeding materials to the finished product. Also, the machine uses materials in limit and prevents the wastage of resources. Because of these two reasons, a company saves both time and money.

-

Customizations

Corrugators have a lot of customization options that increase their usage and benefit the companies. These machines can be customized to produce various shapes and sizes of corrugated boxes. Different types of products require packaging boxes of their own shape and size to prevent the damage from moving inside. Tightly packed products with thermocol sheets as additional layers of protection are much safer while shipping.

-

Durability

Corrugated boxes are made using multiple layers of cardboard that offer them such high durability. Moreover, for absorbing any kind of shock from a fall, these layers have a wave-like pattern between them. Moreover, with a little bit of customization, these boxes can be produced in various shapes and sizes for a perfect fit to the products. This prevents extra movement of products inside the box that can damage them.

-

Eco-Friendly

Corrugated boxes are designed from cardboard material which is easily recyclable and also decomposable. So it does not harm the environment and easily decomposes over time. Also, the automatic machines that produce these boxes use a limited amount of materials as per the system introductions. This reduces the wastage of resources and saves the company from unnecessary expenses.

-

Higher Production

Automatic corrugated box machines can produce a large number of boxes in less time. They are designed for working at peak performance for long hours. Having low downtime and no requirement for frequent maintenance these machines increase the overall productivity of a business. Moreover, in case a business receives a large number of orders then these machines can provide an upper hand to produce the order within promised time.

-

Quality Control

Unlike the manual methods of producing corrugated boxes, the automatic machines maintain consistent quality. These machines can sort out the defective pieces which go through the process once again. Moreover, the chances of human error are also eliminated from the automatic operations. Repetitive tasks take a toll on humans but not on the machines they maintain quality throughout the process.

-

Versatility

There are various types of corrugated boxes that are created using single--, double, and triple-wall corrugated sheets. Automatic corrugated machines are highly versatile and support all these materials for producing the boxes. Every type of box has its own application in different industries.

-

Reduction of Shipping Costs

Shipping cost of a product depends on its weight and packaging materials can increase this cost by adding their own weight. Unlike the others, the corrugated boxes are very light in weight but highly durable and help reduce the shipping cost.

Key Considerations When Choosing a Corrugated Box Machine

There are many factors you should carefully consider while choosing a corrugated box machine for your facility:

-

Production Capacity

The very first thing to identify about corrugators is their production capacity and compare it with your requirements. Every machine has its own capacity to produce corrugated boxes of various shapes and sizes. Miscalculating it can cause you a lot of profit which can be earned through large orders. You must choose a machine that has greater production capacity than you require for bulk orders.

-

Box Type

There are many different types of corrugated boxes with multiple layers of cardboard. So, if you want to choose the right automatic corrugated machine you must know how many types of boxes it can produce. Also, make sure to match that with the type of market you are serving and their demands.

-

Automation

You can choose from different types of automatic corrugated box machines available in the market. For that, you will need to identify the product capacity and overall requirements of the market. With this, you can exactly find out the level of automation you will need. For example, there are manual machines for producing boxes in low quantity, semi-automatic for medium size operations and then there are fully automatic machines for producing corrugated boxes in bulk.

-

Available Space

Another important thing you must be careful about is the available space in your facility for installing the machine. Corrugated box machines are available in various sizes and shapes. You should compare the floor space of your facility with the requirement of installing the machine. The right thing would be to choose a machine that leaves some extra space even after the installation to move around.

-

Budget and Returns

The corrugator can be expensive but it can be a great investment which can offer large profits in the long run. For this, you must identify your budget and spend on the machine that offers the best value under that budget. After a few orders or months, you may see your revenue increasing greatly.

-

Maintenance and Service

High-quality machines used in different fields require regular maintenance and service to perform perfectly. Without the maintenance sessions, the system in the machines can fail. However, frequent maintenance requirements are not good for a business as they increase expenses. So, it will be best to check the machine's specifications and select the one that is made of premium quality material and components. For example, machines made from stainless steel can last up to many years without corrosion or wearing out.

-

Safety Features

Make sure your new corrugated box machine has required safety features for your operator's safety and the workers around it. Modern machines are coming with advanced features like emergency stops, new sensors to detect errors or any system failures, and many more.

Client Testimonials & Reviews

MrANSARI

S. K. PACKAGE MACHINE

We S.K. Package Machine are associated with tradeindia.com for promotional activities and for business development globally since last 7 years. Tradeindia.com service is good, I am 100% satisfied with your service and promotion done by tradeindia. We avail unexpected services from tradeindia.com with complete satisfaction in every aspects.

We are the leading Manufacturer and Exporters of Paper Corrugated Board and Box making machinery, Die Punching machinery and Print pack machinery etc. We have got enrolled with tradeindia.com since 6 years we are very much satisfied with services and we are looking same and long relation with tradeindia.com, All the Best for tradeindia team.

Saravanan

MANO INDUSTRIAL MACHINE TOOLS

I would like to thank tradeindia, who helped us to create our online presence as well as to build up a vast market presence. Tradeindia provided us a unique and a very important platform where we can reach our buyers and sellers very easily. At last I would like to thank tradeindia for helping us to build our brand image in the aggressive and very competitive markets.

Corrugated Box Machine Price List

Product Name | Expected Price |

|---|---|

| Corrugated Box Machine | 550000 |

| Corrugated Box Packaging Machine | 600000 |

| Corrugated Box Machine | 650000 |

| Corrugated Box Making Machine | 760000 |

| Corrugated Box Lock Bottom Pasting Machine | 600000 |

| Corrugated Box Machine | 3000000 |

| Corrugated Box Baling Machine | 325000 |

| Corrugated/Carton Box Making Machine | 600000 |

| Automatic Corrugated/Carton Box Machine | 500000 |

| Corrugated Box Pasting Machine | 2500000 |

This Data was Last Updated on 2025-03-05

Corrugated Box Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Natraj Industries Faridabad, India | 22 Years |

Monu Graphics Faridabad, India | 21 Years |

Associated Industrial Corporation Amritsar, India | 21 Years |

Senior Paper Packing Machinery Mfg. Co. Amritsar, India | 20 Years |

Sheth Printograph Pvt. Ltd. Noida, India | 20 Years |

S. K. Package Machine Vapi, India | 17 Years |

Precision Machines & Automation Mohali, India | 16 Years |

Eie Instruments Private Limited Ahmedabad, India | 15 Years |

Micro Engineers (india) Vasai, India | 10 Years |

Cangzhou Kenuo International Co., Ltd. Cangzhou, China | 10 Years |

Upcoming Tradeshows

CWIEME Shanghai 2025

Wed, 25 Jun, 2025 - Fri, 27 Jun, 2025

Bakery and Commercial Kitchen Equipment 2025

Thu, 12 Jun, 2025 - Sat, 14 Jun, 2025

Vietnam Sport Show 2025

Thu, 14 Aug, 2025 - Sat, 16 Aug, 2025

Water Expo Bhubaneswar 2025

Thu, 10 Apr, 2025 - Sat, 12 Apr, 2025

Singapore International Jewelry Expo 2025

Thu, 10 Jul, 2025 - Sun, 13 Jul, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

Food & Bakery Expo 2025

Fri, 29 Aug, 2025 - Sun, 31 Aug, 2025

MachAuto 2025

Fri, 25 Jul, 2025 - Mon, 28 Jul, 2025

PU TECH 2025

Wed, 09 Apr, 2025 - Fri, 11 Apr, 2025

PHARMATECH & LABTECH EXPO 2025

Thu, 10 Apr, 2025 - Sat, 12 Apr, 2025

Popular Categories