- Tradeindia

- Cnc Machines

- Cnc Router Machine

Cnc Router Machine

(652 products)Red White Kanyakumari Cnc Wood Carving Cutting Router Machine

480000.00 INR/Number

MOQ1 Number

ColorRed White

Product TypeWoodworking Machine

Machine TypeCNC Wood Carving Cutting Router Machine

Machine StyleHorizontal

Voltage240 Volt (v)

PowerElectric

View More

CNC Wood Router Machine - 1300x2500x200 mm, 5 kW Air Cooled Spindle, Remote Control A11 DSP, Automatic Operation, Gray Finish, Electric Power, 220V Single Phase

Price : 380000 INR

CNC Router - Heavy Weld Tube Structure, 1500x2500x300 mm Working Area | High Precision, High Speed, Low Energy Consumption, 24000 RPM Spindle

Price : 410000.00 INR

Perambalur Cnc Wood Working Router Machine - Capacity: 1300Kg Ton/Day

Price : 380000 INR

Neyveli Cnc Wood Working Router Machine - Capacity: 1300Kg Ton/Day

Price : 6500.0 INR

Mohanur Cnc Wood Working Router Machine - Capacity: 1300Kg Ton/Day

Price : 380000 INR

Veppur Cnc Wood Working Router Machine - Capacity: 1300Kg Ton/Day

Price : 380000 INR

Yks-1325 Cnc Routers Machine - Feature: High Precision

440000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

MaterialOther, Mild steel

AutomaticYes

Power SourceElectric

RigidityHigh

Voltage220-440 Volt (v)

View More

Cnc Machine Router Bit - Diameter: 10 Millimeter (Mm)

Price : 350 INR

Yks 6090 Cnc Mini Router Machine - General Use: Industrial

Price : 380000 INR

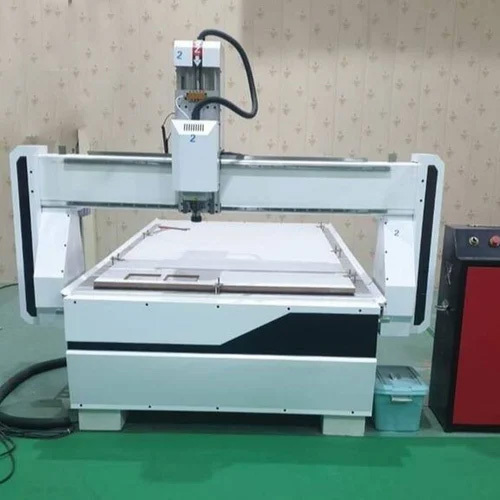

Cnc Router Machine - Color: White

Price : 520000 INR

Fully Automatic Wood Working Cnc Router Machine - Feature: Low Energy Consumption

333000.00 INR/Unit

MOQ1 Unit/Units

ColorOther, Grey & Black

MaterialOther

ComputerizedYes

AutomaticYes

PLC ControlYes

Power SourceElectric

View More

Cnc Wood Routers Machine Capacity: 2.2

Price : nan INR

CNC Router Machine TIR1530DH - Engraves 3D Images on Various Materials | Versatile for Wood, Acrylics, Artistic Detailing and Precision

Price : 615000 INR

Cnc Desktop Router Machine - Color: Blue

Price : 198000.00 INR

Cnc Router Machine Tir1325Sr - Color: White

Price : 575000.00 INR

Cnc Router Machine Tir1530Sr - Color: White

Price : 650000.00 INR

Cnc Router Machine - Hardness: Rigid

MOQ1 Unit/Units

HardnessRigid

UsageIndustrial

MaterialMild Steel

CNCYes

SurfaceGalvanized

Laxmi Engineering Works

Ahmedabad

Trusted Seller

Trusted Seller Super Premium

Super Premium11 Years

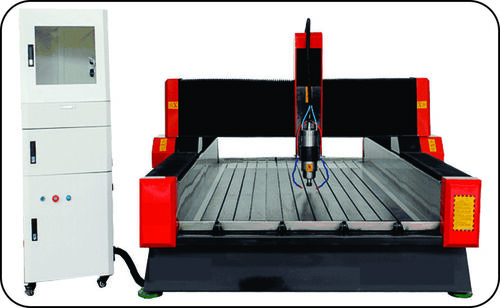

280 V Cnc Stone Router Machine Dimension(L*W*H): 10*5*4 Foot (Ft)

Price: 340000 INR/Unit

MOQ1 Unit/Units

ColorOther

Product TypeRouter Machine

General UseIndustrial

MaterialMetal

Weight (kg)1600 Kilograms (kg)

ComputerizedYes

View More

Industrial Cnc Stone Router Machine Capacity: 500 M3/Hr

Price : 350000 INR

Industrial Cnc Router - Automatic Grade: Automatic

MOQ1 Unit/Units

Product TypeIndustrial CNC Router

General UseIndustrial

ConditionNew

MaterialSteel

Dimensions110 W X 300 L mm Millimeter (mm)

Voltage240 V Volt (v)

Angel India Cad Cam Pvt.ltd.

New Delhi

Trusted Seller

Trusted Seller Super Seller

Super Seller2 Years

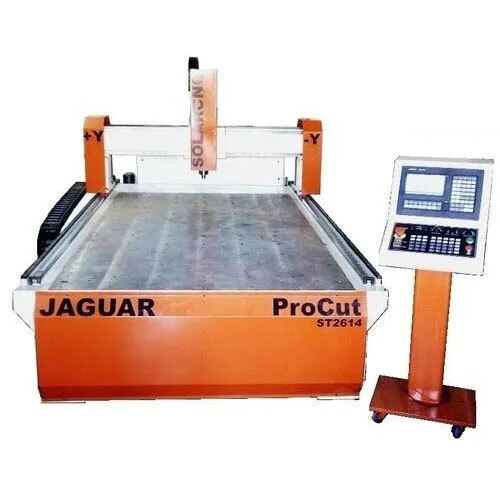

4 Axis Cnc Router Machine - Dimension (L*W*H): 3100*2100*3700 Millimeter (Mm)

Price: 1850000.00 INR/Piece

MOQ1 Unit/Units, Unit/Units, Unit/Units

Product TypeCNC 4AXIS ROUTER

General UseINDUSTRIES

MaterialOther

Weight (kg)3000 Kilograms (kg)

ComputerizedYes

AutomaticYes

Solar Cnc Automation

Vadodara

Trusted Seller

Trusted Seller Super Seller

Super Seller13 Years

View More

3 Axis Cnc Router Machine, Condition: New

Get Best Deal

Cnc Pattern Router Machine - Color: Green

Price : 3500000.00 INR

Cnc Stone Router Machine - Color: Orange

Price : 875000 INR

Cnc 3 Axis Servo Router Machine - Color: Blue

Price : 770000 INR

Wood Pattern Making Cnc Router Machine - Feature: Low Energy Consumption

Price : 2050000 INR

Cnc Wood Router Machine Capacity: 1300X2500X200 Milliliter (Ml)

Price: 550000.00 INR/Piece

MOQ1 Unit/Units

Product TypeWoodworking Machine

Machine TypeRouter

Machine StyleHorizontal

Capacity1300x2500x200 Milliliter (ML)

Voltage440V Volt (v)

PowerElectric

Golden Machinex Corporation

Kolkata

Trusted Seller

Trusted Seller Super Seller

Super Seller14 Years

CNC Router Machine - 1220mm x 2440mm, 18000 Spindle Speed, Electric Power Source | Automatic Tool Change System, User-Friendly Control Interface, High Precision Cutting and Engraving, Minimal Downtime, Durable Build

MaterialSteel, Aluminum

DimensionsVariable

PowerVariable

SpeedVariable

PrecisionHigh

ControlCNC

View More

High Speed Cnc Router 4 Axis Machine

Get Best Deal

Cnc Router Machine With Rotary Attachment Industrial

Get Best Deal

Heavy Duty Router Machine - Capacity: 1000Mm M3/Hr

Price: 450000.00 INR/Piece

MOQ1 Piece/Pieces

ColorWHITE , BLUE

Product TypeWoodworking Machine

Machine TypeRouter

Machine StyleVertical

Capacity1000mm

PowerElectric

View More

Blue Vertical Cnc Wood Router Machine

Price : 39000 INR

CNC Router Machine - Steel/Aluminum, 1000x1500mm, 220V, 12000 RPM | High Efficiency, Corrosion Resistance, Longer Functional Life, Low Maintenance

Price Trend : 550000.00 - 900000.00 INR

CNC Router - Stainless Steel, 1300x2500x200 mm, Orange and White | 9Kw HSD Spindle, 8-Tool ATC, 20000 mm/min Max Speed, 7Hp Vacuum Pump

Price: 1000000 INR/, Unit

MOQ5 , Unit/Units

Product TypeRouter with Vacume Table

ShapeRectangle

Weight1500 Kilograms (kg)

ColorOrange And White

MaterialStainless Steel

Timus Tooling System Private Limited

New Delhi

Trusted Seller

Trusted Seller Super Seller

Super Seller10 Years

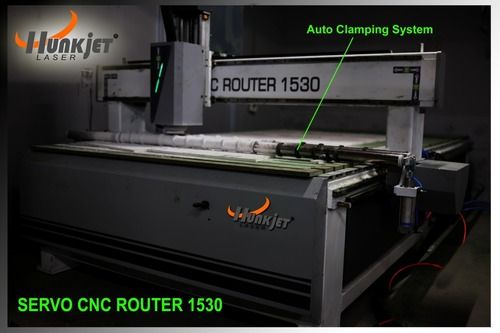

3D CNC Router Cutting Machine - Metal Structure, 220 Volt Power Source, Gray Color | High Precision, Low Maintenance, Ergonomic Design, Three Cutting Axes

MaterialSteel

Dimensions1530mm

Axes3 axes (XYZ)

Guide RailLinear

ControlCNC

ClampingAuto

View More

Blue Wood Pattern Making Cnc Router Machine

Price : 470000 INR

White High Speed Cnc Router Wood Working Machine

Price : 480000.00 INR

Red Wood Cnc Router Cutting And Engraving Machine

Price : 350000 INR

Grey Wood Cnc Router Machine With Servo Motor

Price : 630000 INR

White Wood Cutting 3D Cnc Router Machine With T Slot Table

Price : 470000 INR

White Automatic Wood Working Cnc Router Machine With Auto Clamping

Price : 600000 INR

Basic Router Wood Working Machine - Feature: High Efficiency

Price: 450000 INR/Pack

MOQ1 Pack/Packs

General UseIndustrial

MaterialSteel

ComputerizedNo

AutomaticNo

FeatureHigh Efficiency

WarrantyYes

Multi Head Copy Router Machine

Price Trend: 300000.00 - 500000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeMulti Head Copy Router Machine

General UseRouting of aluminum, PVC, and light metal profiles

MaterialOther, Aluminum and Steel structure

TypeOther, Copy Router Machine with Multi Head

CapacityThree profiles simultaneously (typical)

Weight (kg)1100 kg

Zenith Engineering And Equipments Private Limited

Vadodara

Trusted Seller

Trusted Seller Premium Seller

Premium Seller11 Years

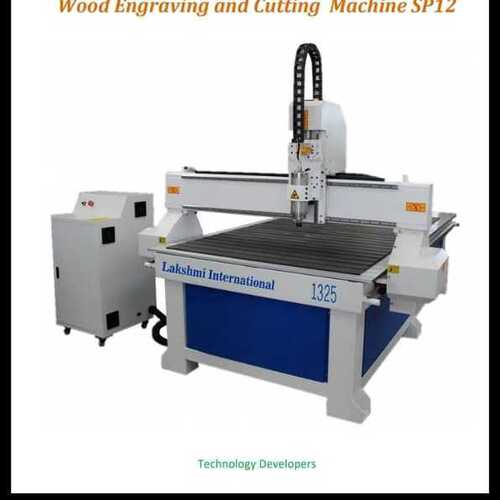

CNC Wood Router Machine - 4-Head Design, High Speed Multi-Color Precision Control | Independent Spindle Movement for Enhanced Productivity

Spindle Power4KW

Working Area1300x2500mm

MaterialSteel, Aluminum

Control systemDSP

Spindle Speed18000RPM

Repeatability0.01mm

Lakshmi International

Coimbatore

Trusted Seller

Trusted Seller Premium Seller

Premium Seller6 Years

View More

CNC Wood Router Machine - Metal, 1300x2500mm, White | High Rigidity, 25000rpm Spindle Speed, Automatic PLC Control

Price : 550000 INR

CNC Wood Carving Machine - 1800x3000x800mm, Gray and Blue | 1000kg Weight, Electric Power, Automatic Router with Servo or Stepper Motor, 12 Month Warranty

Price : 470000 INR

CNC Router Machine - Stainless Steel Build , White Color, Automatic Bar Feeder , 1 Year Warranty , Electric Power Source

Price : 55000 INR

Sp12 Cnc Wood Router Machine Capacity: 1 M3/Hr

Price : 380000.00 INR

Cnc Wood Router Machine - Feature: High Precision

Price : 400000.00 INR

FAQs Related to Cnc Router Machine

Some of the best CNC machines for beginners include:

- 1. Carbide 3D Shapeoko 4.

- 2. Comgrow ROBO 3018 CNC Router.

- 3. Stepcraft D-Series.

- 4. MYSWEETY 2 in 1 CNC 3018 Pro.

- 5. X-Carve.

- 6. Genmitsu 3020 Pro Max CNC Router Kit.

- 7. Genmitsu 3020-Pro Max CNC Router Kit.

- 8. FoxAlien 4040-XE CNC Router Machine.

- 9. BobsCNC E3.

Prices range from $5,000 to $10,000 for the three-axis devices that are the most fundamental. Costs for machines in the middle level are typically between $25,000 and $50,000. Most of the top CNC routers, including 4-axis and 5-axis models, may set you back $50,000 or more.

- 1. Precision and automation

- 2. High-quality performance and work

- 3. Enhanced factory productivity

- 4. Reduces waste

- 5. Lessen human errors

Fully Automatic CNC Carving Machine

Price: 590000.00 INR/Number

MOQ1 Set/Sets, Set/Sets, Set/Sets

ColorOther, Blue/White

Product TypeFully Automatic CNC Carving Machine

General UseWood, MDF, Acrylic, Stone, Aluminum Carving

MaterialOther, Steel Frame

TypeOther, CNC Carving

Capacity800 mm/s

View More

Advertising CNC Router Machine

Price : 545000.00 INR

CNC Router Machine - Steel, 1325mm | 3KW Power, 18000 RPM Spindle Speed, Easy Installation, High Accuracy for Woodworking & Engraving

Price : 395000.00 INR

Automatic CNC Router Machine - Acrylic, Plywood, MDF, PVC, Electric Power 220V | High Speed, No PLC Control, Non-Automated System

Price : 375000.00 INR

Door Carving Machine - CNC Router Tool | Economical Operation, Low Maintenance, Premium Grade Components, Sophisticated Technology

Price : 375000.00 INR

CNC Wood Acrylic Router Machine

Price : 395000.00 INR

Wood Working CNC Router Machine

Price : 415000.00 INR

Computer Controlled CNC Router Machine

MaterialSteel,Aluminum

Dimensions1500x1000x1000mm

Power3KW

SpindleAir-cooled

ControlDSP

Axes3

Gruntech Mechanism Private Limited

South 24 Parganas

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

View More

Cnc Wood Router Machine - Machine Style: Horizontal

Price : 700000 INR

CNC Wood Router Machine - Metal, 400 x 600 mm Table Size, 440 Volt, AC Motor, 24000 RPM Spindle Speed | Automatic Operation, Warranty Included

Price : 450000 INR

Automatic Stone CNC Router Machine

Price : 400000 INR

High Precision Automatic CNC Wood Router

Price : 400000 INR

Cnc Router Machine - General Use: Industrial

Price : 425000.00 INR

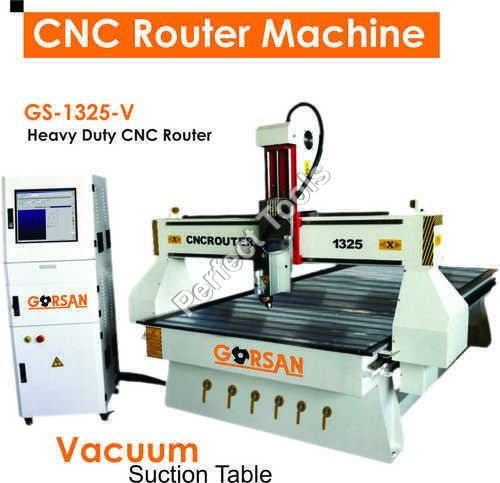

Cnc wood router machine

Price: 790000 INR/Unit

MOQ1 Unit/Units

Supply Ability1 Per Month

Delivery Time1 Months

Sample AvailableYes

Gorsan Impex Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Cnc Router Machine

MaterialSteel,Aluminum

DimensionsCustomizable

Power3-Phase

SpindleHigh speed

ControlNumerical

SoftwareCompatible

Mehta Cad Cam Systems Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller5 Years

View More

CNC Router - High Precision, Versatile Size for Woodworking and Metalworking Production | Quiet Operation, User-Friendly Interface, Enhanced Cutting Accuracy

Price : 785000.00 INR

CNC Router Machine - High Precision, Versatile Design for Wood, Plastic, and Metal Applications - User-Friendly Interface, Dust Collector Compatibility

Price : 785000.00 INR

Cnc Wood Router - Color: Grey

Motor Power3KW

Spindle Speed18000-24000 rpm

Working Area1300*2500mm

Machine Dimensions2500*2000*1600mm

Weight800kg

MaterialAluminum alloy

Infinity Designs Solutions

Kolkata

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

View More

Cnc Router Engraving And Cutting Machine - Automatic Grade: Automatic

Price : 650000 INR

High Speed Cnc Router Machine - Automatic Grade: Automatic

Price : 775000.00 INR

CNC Wood Carving Machine - Versatile CNC Router for Wood, Plastic, Foam, Composites & Soft Metals | Precision Cutting, Engraving, and Milling Capabilities

Price : 500000.0 INR

1325D Cnc Router Machine - General Use: Industrial

Price : 650000 INR

1325C Cnc Router Machine - General Use: Industrial

Price : 750000 INR

1325A+ Cnc Router Machine - General Use: Industrial

Price : 650000 INR

Reinforcement Channel Screwing Machine - Color: Gray

Price: 255000.0 INR/Piece

MOQ1 Piece/Pieces

ColorGray

Product TypeWater Drain Slot

General UseFor Doors & Windows Making

MaterialOther

Weight (kg)88 Kilograms (kg)

ComputerizedNo

Taalin Machinery & Robotics Pvt. Ltd.

Greater Noida

Trusted Seller

Trusted Seller Premium Seller

Premium Seller5 Years

High Performance Durable CNC Router Machine

ModelPLT-1325

SpindleSingle spindle

MaterialSteel, Aluminum

Dimensions1300x2500x1000mm

Power3KW

ControlDSP

View More

CNC Router Machine

Get Best Deal

Plt- 1325 Cnc Router Machine - General Use: Industrial

Price : 540000.00 INR

Double Head Cnc Router Machine - Feature: High Speed

Price: 600000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

MaterialStainless Steel

ComputerizedNo

AutomaticYes

Power SourceElectric

FeatureHigh Speed

Semi Automatic Portable Routing Machine

Price: 60000 INR/Unit

MOQ100 Unit/Units

Product TypePortable Routing Machine, Other

TechnologyCNC

Power SourceElectricity

Operating TypeSemi Automatic

Surface TreatmentPainted

Usage & ApplicationsIndustrial

Shri Baba Ji Industries

Faridabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

CNC Router Machine - 1200x1200mm Working Area, Dual Head Efficiency and Precision | 6000-24000 RPM Speed, 0.005mm Working Delicacy

MOQ1 Unit/Units

Table Size1340 to 1420mm

Ruei Industries Private Limited

Coimbatore

Trusted Seller

Trusted Seller Premium Seller

Premium Seller15 Years

View More

Woodworking Machine 1200 X 1200 X 100 Mm Cnc Router

Price : 600000 INR

5.5Kw Cnc Router Machine - Feature: High Speed

MOQ1 Unit/Units

General UseIndustrial

MaterialStainless Steel

AutomaticNo

Power SourceElectric

RigidityHigh

Voltage230 Volt (v)

Hubei Meishu Technology Co.ltd

Jingzhou

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

CNC Router Machine - Stainless Steel, High Speed Design , Automatic Operation for Wood, MDF, Acrylic, Plastic, Aluminum Cutting and Engraving

Price: 600000 INR/Unit

MOQ1 Unit/Units

Product TypeCNC Router Machine

General UseWood, MDF, acrylic, plastic, aluminum engraving and cutting

MaterialMetal

ComputerizedYes

AutomaticYes

ColorGreen

View More

Wood Master High Speed Cnc Router Machine - Color: Black

Price : 550000.00 INR

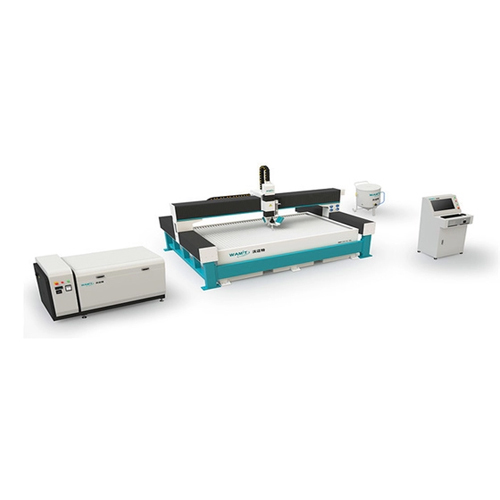

Stone CNC Router - Stainless Steel, 420 Volt, White and Blue Color | Automatic Function, Precision Stone Carving and Engraving Machine

Price : 550000 INR

Cnc Wood Engraving Router Machine - Material: Metal

Price : 600000 INR

Stone Cnc Router Machine - Material: Stainless Steel

Price : 500000 INR

Cnc Router Machine - Color: Green

Price : 420000 INR

Cnc Router Machine - Automatic Grade: Automatic

Price: 345000.00 INR/Unit

MOQ1 Unit/Units

ColorWhite

MaterialAcrylic

TypeHorizontal

CNC Or NotCNC

ComputerizedNo

AutomaticYes

View More

Vacuum Bed Cnc Router Machine - Automatic Grade: Automatic

Price : 490000.00 INR

Wood Cnc Router Machine - Feature: High Precision

Price : 400000 INR

CNC Router Machine - Stainless Steel, 450 kg Weight, Gray Color | 3 kW Electric Power, PLC Control, High Precision, Automatic Features

Price : 225000 INR

Vacuum Bed Cnc Router Machine - Color: Gray

Price : 465000 INR

Acrylic Cnc Router Machine - Color: Gray

Price : 1650000 INR

Semi Automatic Lock Hole Cum Copy Routing Machine Industrial

Motor Power1.5KW

Spindle Speed8000-12000rpm

Cutting Depth50mm

Table Size600x400mm

Machine Weight200kg

Dimensions1200x800x1500mm

Be Rightbuild Solutions Pvt. Ltd.

Gurugram

Trusted Seller

Trusted Seller Premium Seller

Premium Seller7 Years

CNC Router Pattern Machine

TypeGantry type

Spindle power0.8-6KW

ControllerHandheld DSP

Drive systemRack & Pinion

Table materialAluminum T-slot

Table protectionPVC sheet

View More

CNC Wood Router - Electric, 220-415V, White | Precision Cutting, High-Speed Operation, User-Friendly Interface

Price : 600000 INR

Cnc Router Machine Atc - General Use: Industrial

Price : 950000 INR

Double Head CNC Router Machine - 6 KW Air Cooled, 1300x2500mm Working Area | High Speed, Precision 0.1mm, 18000 RPM Spindle Speed, Automatic

Price : 900000 INR

High Speed CNC Router - Stainless Steel, Vertical Design | High Precision, Low Energy Consumption, PLC Control, Automatic Operation

Price: /Piece

MOQ1 Unit/Units

Glue thickness3.5 Millimeter (mm)

Product TypeHigh Speed CNC Router

General UseIndustrial

MaterialStainless Steel

Other NamesAdhive

TypeVertical

Popular Cnc Router Machine

Client Testimonials & Reviews

BhupendraYadav

CNC SOLUTIONS

We are pleased to associate with tradeindia (Indiaa s largest B2B portal) for online promotion of our products. Such online platform will help us a lot for market reach, Brand-promotion and New Market Exploration. We are very happy to become a member of tradeindia.com. All the best an efficient team tradeindia for many more milestones

Tradeindia.com provided excellent quality services and proved to be very helpful to expand our business to reach new heights through their inquires. We are able to generate sales from the actual users, large companies and foreign companies for our 'Pioneer' All geared Lathe Machines. We got prompt replies and personal visits from tradeindia executives from time to time. We recommend other companies to join tradeindia.com, in order to grow their business in India as well as Foreign Countries. Their Mobile App is also very useful for potential buyers. Thank you tradeindia.com.

Cnc Router Machine Price List

Product Name | Expected Price |

|---|---|

| 12 Ft Single Head CNC Router Machine | 485000 |

| 8 Ft Single Head CNC Router Machine | 385000 |

| 10 Ft Single Head CNC Router Machine | 425000 |

| Smart Nesting Cnc Router Machine | 177300 |

| Cnc Router Machine 1625 K3 | 550000 |

| Durable Cnc Router Machine | 485000 |

| 1325 CNC Servo Router Machine | 435000 |

| Cnc Router Machine | 450000 |

| Cnc Router Machine | 730000 |

| CNC Router Machine | 390000 |

This Data was Last Updated on 2025-12-07

Cnc Router Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Intimate Machine Tools Rajkot, India | 15 Years |

Ruei Industries Private Limited Coimbatore, India | 15 Years |

Golden Machinex Corporation Kolkata, India | 14 Years |

Solar Cnc Automation Vadodara, India | 13 Years |

Hunkjet Laser Pune, India | 12 Years |

Perfect Tools New Delhi, India | 12 Years |

Laxmi Engineering Works Ahmedabad, India | 11 Years |

Didac International New Delhi, India | 11 Years |

Zenith Engineering And Equipments Private Limited Vadodara, India | 11 Years |

K Tech Cnc Hyderabad, India | 11 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

17th Coating Korea - Coating Adhesive Film Industry Expo 2026

Wed, 25 Mar, 2026 - Fri, 27 Mar, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

LogiMAT India 2026

Thu, 05 Feb, 2026 - Sat, 07 Feb, 2026

INTERNATIONAL CAFE AND BEVERAGE SHOW (ICBS) 2026

Thu, 07 May, 2026 - Sat, 09 May, 2026

AutoTechnika 2026

Fri, 05 Jun, 2026 - Sun, 07 Jun, 2026

SAIFEE BURHANI EXPO 2025

Fri, 19 Dec, 2025 - Sun, 21 Dec, 2025

Power On 2026

Fri, 23 Jan, 2026 - Sun, 25 Jan, 2026

CIFF - China International Furniture Fair Guangzhou 2026

Wed, 18 Mar, 2026 - Sat, 21 Mar, 2026

Bharat Pharma Expo 2026

Thu, 11 Jun, 2026 - Sat, 13 Jun, 2026

Popular Categories