- Tradeindia

- Bricks

- Cement Brick

Cement Brick

(2622 products)Interlocking Paver Cement Channel

Price Trend: 25.00 - 60.00 INR/Square Foot

MOQ10-100 Square Foot/Square Foots

Product TypeInterlocking Paver

Main MaterialCeramic

Size60 mm

Acme Cc Products

Gurugram

Trusted Seller

Trusted Seller6 Years

Super Seller

Super SellerGray Fly Ash Cement Brick

Price: 05 INR/Piece

MOQ3000 Piece/Pieces

Bricks TypeConcrete Bricks

TypeCommon Bricks

ColorGray

Mohta Cement Pvt Ltd

Indore

Trusted Seller

Trusted Seller13 Years

Premium Seller

Premium SellerWhite Matte Cream London Brick

Bricks TypeLondon Brick, Other

ColorWhite

Size215 x 102 x 65 mm

Prayag Clay Product Limited

Varanasi

Trusted Seller

Trusted Seller1 Years

Premium Seller

Premium SellerCement Brick

Price: 4000 INR/Cubic Meter

MOQ30 Cubic Meter/Cubic Meters

Payment TermsTelegraphic Transfer (T/T), Others, Western Union, Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque

Supply Ability500 Per Day

Delivery Time24 Hours

Acid-Resistant Color Coated Cement Brick

Price: 25 INR/Piece

MOQ2000 Piece/Pieces

TypeCommon Bricks

SizeDifferent Sizes Available

PorositySolid

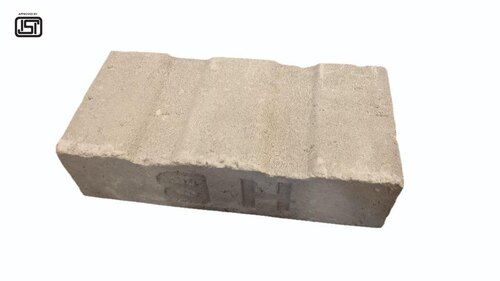

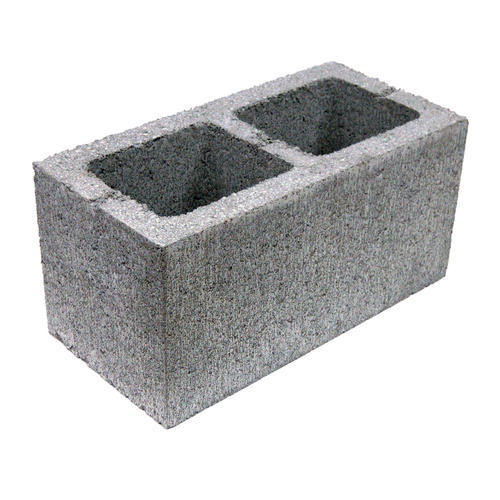

Grey Concrete Brick

Price: 9.5 INR/Piece

MOQ4500 Piece/Pieces

Water Absorption<15%

Dimension (L*W*H)230 x 110 x 70 Millimeter (mm)

Compressive Strength+8.00 Newtons per Millimetre Squared (N/mm2)

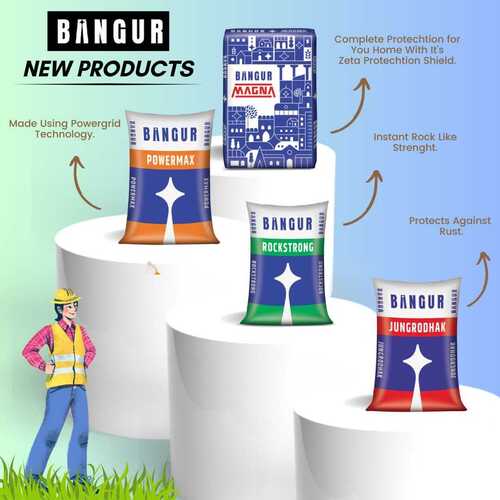

Bangur Cement

Price: 270.00 INR/Bag

MOQ100 Bag/Bags

Supply Ability200 Per Day

Delivery Time2 Days

Main Domestic MarketWest Bengal

9 in x 3 in x 2 in Size Rectangular Shape Fly Ash Cement Bricks

Bricks TypeFly-Ash Bricks

ColorGray

SizeAll

Non-Polluting Crack Resistant And High Strength Grey Cement Bricks For Construction

Price: 10 INR/Piece

MOQ10000 Piece/Pieces

Working Life1 Years

Bricks TypeConcrete Bricks

MaterialQuartz

Concrete Fly Ash Bricks - Color: Any Color

Price Trend: 8.00 - 10.00 SGD ($/Piece

MOQ5000 Piece/Pieces

Bricks TypeClay Bricks

TypeCommon Bricks

ColorAny color

Top Rated Products

Non-Polluting Crack Resistant And High Strength Grey Cement Bricks For Construction

Goyal Cement Blocking

FAQs Related to Cement Brick

Cement Ash Brick

Price Trend: 3.00 - 4.80 INR/Piece

MOQ2000 , Piece/Pieces

Supply Ability30000 Per Day

Delivery Time1 Days

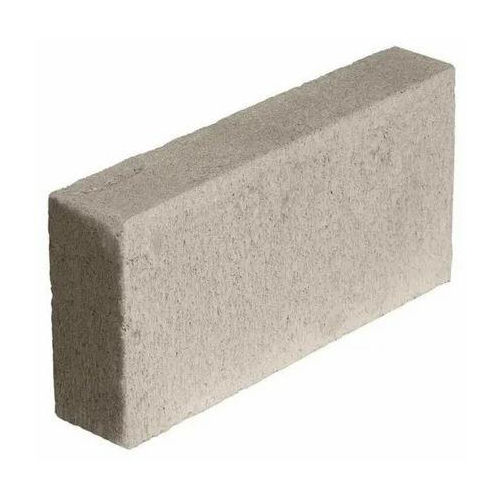

Grey Cement Bricks

MOQ1000 Piece/Pieces

Bricks TypeOther, Paving Bricks

ColorGray

ShapeRectangular

Gray Acc Fly Ash Brick

Price: 6.6 INR/Piece

MOQ5 Piece/Pieces

Water Absorption5

Dimension (L*W*H)250 * !20 * 75 Millimeter (mm)

Compressive Strength12 Newtons per Millimetre Squared (N/mm2)

Rectangular Shape Fly Ash Bricks For Wall And Building Use Water Absorption: Yes

Price Trend: - 49.00 INR/Square Inch

MOQ750 Square Inch/Square Inches

Water AbsorptionYES

Bricks TypeFly-Ash Bricks

MaterialNatural Slate

Natural Stone Concrete Brick

Price: 32 INR/Piece

MOQ100 Piece/Pieces

Product TypePaver Block

Main MaterialCement & Concrete

Surface TreatmentSmooth

9X4X3 Cement Bricks - Color: Gray

Price: 7.50 INR/Piece

MOQ2000 Piece/Pieces

Bricks TypeConcrete Bricks

ColorGray

Size9x4x3 inch

Concrete Bricks - Dimensions: 230 X 110 X 75 Millimeter (Mm)

Price: 8.50 INR/Piece

MOQ10000 Piece/Pieces

MaterialConcrete

Tensile Strength15 Newtons per Millimetre Squared (N/mm2)

Dimensions230 x 110 x 75 Millimeter (mm)

Cement Sand Bricks

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Main Export Market(s)Asia

Gray 9X4X3 Inches 2.2 Megapascals Rectangular Solid Cement Brick

Price: 7 INR/Piece

MOQ6500 Piece/Pieces

Water Absorption12%

Compressive Strength2.2 Megapascals (MPa )

Dimension(L*W*H)9x4x3 Inch (in)

Gray Fly Ash Bricks - Porosity: Solid

Price: 40 INR/Piece

MOQ1800 Piece/Pieces

Bricks TypeFly-Ash Bricks

MaterialClay, Other

TypeHandmade Bricks

Gray 9X4X3 Inches Rectangular Heat And Sound Insulation Solid Cement Brick

Price: 35 INR/Piece

MOQ1250 Piece/Pieces

Drying Shrinkage0%

Water Absorption12%

Dimension(L*W*H)9x4x3 Inch (in)

Gray Premium Quality 9 X4X3 Inch Size Hand Made Cement Bricks

Price: 25 INR/Piece

MOQ1800 Piece/Pieces

Compressive Strength17.5 Megapascals (MPa )

Working Life60 Years

Water Absorption10%

Rectangular Gray Cement Bricks

Price: 9 INR/Piece

MOQ50000 Piece/Pieces

Bricks TypeOther, Cement Bricks

ColorOther, Gray

SizeComes in various sizes

Rectangle 9 Inch Cement Bricks

Payment TermsOthers, Telegraphic Transfer (T/T)

Delivery Time2 Week

Sample PolicyContact us for information regarding our sample policy

Fire Resistance And Heat Resistance ACC Cement Brick

Price: 2000 INR/Piece

MOQ500 Piece/Pieces

Finenesscement block

Soundnesscement block

Bending Strengthcement block

Gray Crack Resistance Weather Resistance Rectangular Cement Bricks For Construction

Price: 900 INR/Piece

MOQ500 Piece/Pieces

Porosity (%)99

Working Life12 Months

Compressive Strength56 Newtons per Millimetre Squared (N/mm2)

Latest from Cement Brick

What Are Cement Bricks Called?

What Are Cement Bricks Used For?

- Grade C blocks have a density of greater than 1000 kg/m3 and are used in the construction of walls that do not carry any weight.

- Grade B bricks are used for load-bearing walls and have a density that is lower than 1500 kg/m3 on average.

- Grade A bricks are the highest quality available. They have a minimum density of 1500 kg/m3 and are utilized for load-bearing walls.

What Is the Advantage of Cement Bricks?

Are Cement Bricks Strong?

Client Testimonials & Reviews

Debapriya

RUPA ECO BRICK

We are pleased to associate with tradeindia.com to promote our products online. Such online platform will definitely help a lot for new market reach and exploration. It is grateful to you for the quality of the work done to promote our products on your portal, as well as for the quality of the work on the preparation of a 4-page site on the basis of your directory. We consider it possible to recommend Tradeindia company as a qualified and competent organization in solving such challenges. All the best to tradeindia for achieving many more milestones ahead.

Cement Brick Price List

Product Name | Expected Price |

|---|---|

| Fly Ash Bricks | 8 |

| Wall Bricks | 8 |

| Gray Cement Brick | 8 |

| Cement Bricks | 15 |

| Cement Bricks | 40 |

| Fly Ash Bricks | 40 |

| Gray Fly Ash Bricks | 40 |

| Fly Ash Cement Bricks | 7.5 |

| Grey Cement Brick | 18 |

| Grey Rectangular Cement Brick | 10 |

This Data was Last Updated on 2024-12-12

Cement Brick Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Mohta Cement Pvt Ltd Indore, India | 13 Years |

Hem Care Corporation Rajkot, India | 12 Years |

Balaji Enterprises Gurugram, India | 12 Years |

Drp Infratech Mhow, India | 11 Years |

M.r. Bricks Indore, India | 11 Years |

C.k. Elnet Private Limited Mohali, India | 8 Years |

Portland Trading Co. Kolkata, India | 7 Years |

Acme Cc Products Gurugram, India | 6 Years |

Rupa Eco Brick Murshidabad, India | 6 Years |

Mantralaya Floorings Hyderabad, India | 4 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

National Expo Raipur 2025

Sun, 19 Jan, 2025 - Wed, 22 Jan, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

Popular Categories