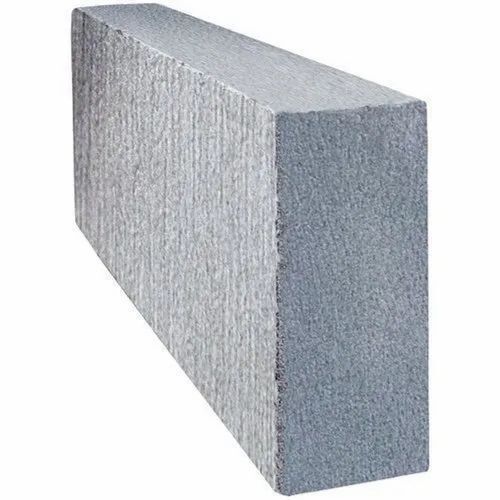

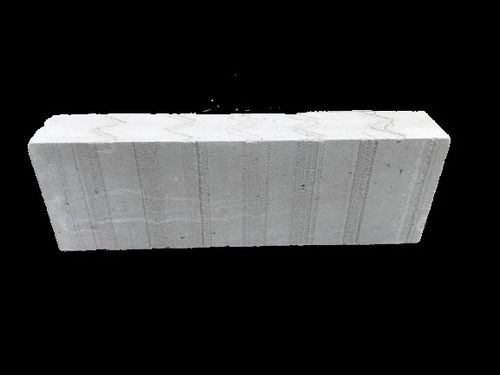

Aa Block Fly Ash Brick Dimension(l*w*h): 24"/25"x8"/10"/12"x 4"/6"/8" Inch (In)

Price: 3400 INR

Get Latest Price

Minimum Order Quantity :

100

In Stock

Product Specifications

| Water Absorption | not in particular |

| Dimension (L*W*H) | 24"/25"X8"/10"/12"X 4"/6"/8" Inch (in) |

| Material | Quartz, Clay, Sandstone, Other, Natural Slate |

| Type | Engineering Bricks |

| Size | all type shape and size available |

| Porosity | Porous |

| Technics | Steam-Cured |

| Feature | Non-Polluting, High Strength, Abrasion Resistance, Fire Brick, Light weight, Heat-insulation, Sound insulation, Non-toxic, Acid-Resistant, Other, Fire-retardant |

| Payment Terms | Cash Against Delivery (CAD), Cash on Delivery (COD), Cheque, Western Union, Others, Delivery Point (DP), Cash in Advance (CID), Cash Advance (CA) |

| Supply Ability | After order Per Day |

| Delivery Time | 24x7 Years |

| Sample Available | Yes |

| Sample Policy | Free samples are available |

| Packaging Details | AAC Block Adhesive is a high performance light weight adhesive. It is a versatile thin jointing material for laying AAc blocks, fly ash bricks, concrete blocks, etc. ... AAC Block adhesive is pre-mixed, easy to apply high quality mortar comprising of cement, graded and admixtures. |

| Main Export Market(s) | Asia |

| Main Domestic Market | All India |

| Certifications | Composition of AAC blocks80% of the volume of an AAC block is air. The blocks are easy to install, nail, drill and cut for pipes and conduits .We manufacture the AAC blocks in a variety of sizes. The raw materials we use to manufacture the these blocks are cement, sand, fly ash, gypsum, lime and water. |

Product Overview

Key Features

AAC is produced from the common materials lime, sand, cement and water, and a small amount of rising agent. After mixing and molding, it is then autoclaved under heat and pressure to create its unique properties. AAC has excellent thermal insulation and acoustic absorption properties. AAC is fire and pest resistant, and is economically and environmentally superior to the more traditional structural building materials such as concrete, wood, brick and stone.

At the point when AAC is blended and cast in structures, a few compound responses occur that give AAC its light weight (20% of the heaviness of cement) and warm properties. Aluminum powder responds with calcium hydroxide and water to frame hydrogen. The hydrogen gas froths and copies the volume of the crude blend making gas rises to 3mm (a inch) in distance across. Toward the end of the frothing procedure, the hydrogen escapes into the air and is supplanted via air.

AAC Blocks is a unique and excellent type of building material due to its super heat, fire and sound resistance, AAC blocks are lightweight and offers ultimate workability, flexibility and durability. Its main ingredients include sand, water, quicklime, cement and gypsum. The chemical reaction due to the aluminum paste provides AAC its distinct p

Company Details

Business Type

Exporter, Importer, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler, Retailer, Dealer, Fabricator, Producer

Employee Count

20

Establishment

2006

Working Days

Monday To Sunday

GST NO

09BHQPK1260G1Z8

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 09BHQPK1260G1Z8

Lucknow, Uttar Pradesh

Proprietor

Mr Waqar Alam

Address

No. 596, Pb/407, Kashmiri Bagh, Ring Road, Dubagga, Lucknow, Uttar Pradesh, 226003, India

aac bricks in Lucknow

Report incorrect details