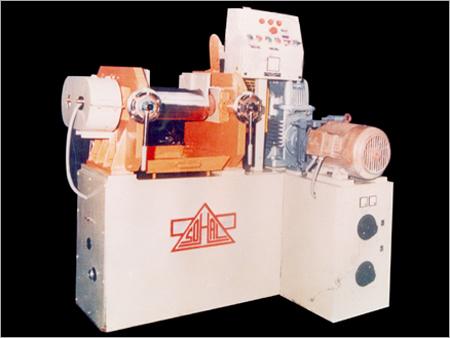

Xk-400 Rubber Open Mixing Mill - Iron Material, 4240x1780x1760 Mm Dimensions, 45 Kw Power Consumption | Compact Structure, Multiple Speed Options, Abrasion Resistant Rolls, Perfect Safety Features

Price: 38,000 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Type | XK-400 |

| Material | iron |

| Capacity | 13~35 Kg/hr |

| Computerized | Yes |

| Automatic Grade | Manual |

| Control System | Human Machine Interface |

| Power Consumption | 45 Kilowatt (kW) |

| Weight | 8000 Kilograms (kg) |

| Dimension(L*W*H) | 4240*1780*1760 Millimeter (mm) |

| Warranty | 1 year |

| FOB Port | Shanghai Port |

| Payment Terms | Paypal, Telegraphic Transfer (T/T), Others |

| Supply Ability | 10 Per Month |

| Delivery Time | 45 Days |

Product Overview

Key Features

1. Tailored and compact structure, easy to operate.

2. There are many speeds and speed ratios of our rubber magnet mixing mill for your options, which can satisfy most customers' formula and processing requirements

3. Frame, frame cap and base, looking very nice, are welded and treated by annealing for stress relieving.

4. Chilled alloy cast iron roll is abrasion resistant with long service life. The speed reducer is the hard-tooth surface gear reducer of Class 6 precision, which has long service life and low noise.

5. Perfect emergency stop device can ensure the safety of personnel and equipment.

6. The seal structure with special design can eliminate the leaking phenomenon of lubricating oil.

7. Stock pan is easy to clean up with dislodging device

8. Human nature designed operating system reduces labor intensity.

9. Modular structure offers various structures for customers' option.

10. The flexible design system can satisfy customers' special design requirements within the shortest time...

11. A load test running will be made to the assembled equipment in our company to save debugging time for customers...

Packaging

Equipment painting completed before delivery, and then wrapped with stretch film, avoid rubbing the paint off the surface, wooden packaging can be customized, key parts, such as electronic control box, will be wrapped by shockproof packaging materials, and then packed in wooden cases.

FAQ

1. What does your factory do regarding quality control?

We pay much more importance to quality control from the very beginning to the end of production. Every machine will be fully assembled and carefully tested before shipment.

2. What's the machine quality guarantee?

Quality guarantee time is one year.We choose world famous brand components to keep our machine in perfect working condition.

3. Are you able to give installation and commissioning overseas?How long time will it take?

Yes, we can supply overseas service and technical support but customer needs to pay for the cost of the installation. Small machine usually takes within 2~3 days. Big production line usually takes about 30 days.

4. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order. The core of our company culture is innovation,quality,integrity and efficiency. Also we have had many good cooperation with world famous rubber production manufacturers.

If you come to our factory, we can show the user around us.

5. How can we go to your side?

We are located in Qingdao City, Shandong province, China. The name of airport is Qingdao liuting airport. We will pick up you at the airport.

Our Services

a Our engineers can design target machines for customers and send them the drawing to confirm. We are always on the side of saving your cost.

a In the process of production, we will take photos and send to customers for their track the progress.

a Documents such as packing list, commercial invoice, and bill of lading etc. will be sent after the delivery.

a We could supply free English foundation DWG, installation drawing, user guide, maintenance manual and part drawing.

a We supply overseas engineer service and help to train your workers to operate the machine.

Company Details

Kaichi was founded in 1988 by Mr. Chen Jianwei and other partners,mainly engaged in rubber and plastic machinery Research,development and production,the hydraulic rotary mixer field competitiveness ranked first. Rubber double screw extruder China first sets in 2010,the success of R & D,used in Changzhou in the rubber and plastic products Co., the result is beyond expectation. Located in the industrial production base :Gaochun Economic Development Zone in Nanjing, covers an area 20,000 square meters.The factory is surrounded by highways, which is very convenient for customers to visit. Our products mainly rubber machinery and equipment for leading ,respectively,rubber cutting system,mixing system, film cooling system,automatic feeding system,extruding, molding system etc... Product form is mechanical body,transmission system & control system. Presales specialist to provide the best equipment selection guidance,customer service all in one service (selection,installation,commissioning & maintenance training) Kaichi is currently in Turkey,India and other counties to open sales center for international service.In the country to set up 9 subsidiaries,and have new ideas,technology & deep blue technology ,at the same time,set up a research center,machinery equipment tire foam rubber machinery & filled master-batch equipment research center.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

67

Establishment

2005

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Nanjing, Jiangsu

Mr Edmund Chen

Address

No. 16, Songyuan Road, Economic Development Zone, Gaochun, Jiangsu, District, Nanjing, Jiangsu, 210008, China

rubber processing machine in Nanjing

Report incorrect details