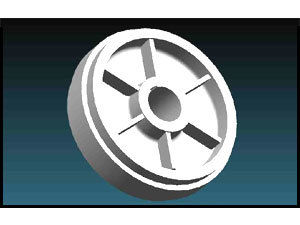

Wheel Disc - Titanium Carbide Material, High Erosion Resistance At 540 C, 24000 Rpm Capability, Reduced Vibration And Maintenance Costs

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Cause Of the problem: Main cause of wear is erosion at a temperature of 540 C along with centrifugal force due to high rotational speed. The impinging material is hard and has a tendency of caking. This reduces some wear but increases imbalance that may cause vibration and subsequent failure due to variance in centrifugal forces.

Our Solution: Boron Carbide was replaced by wear part made of machinable and harden able Titanium Carbide. This material can be processed more easily to manufacture this rather complex profile. TiC is not brittle, has high erosion resistance and retains hardness at an elevated temperature of 540 C. The low density does not induce stress on the bearings of the wheel disc that is rotating at 24000 RPM. This application has now been standardized. The wear part is inspected every month during the routine maintenance schedule to study the thinning and to decide on replacement period. The end user managed to save a huge amount of money because of avoidance of sudden break down and unscheduled shut down.

Company Details

Focusing on a customer-centric approach, KEEPSAKE ENGINEERING CONSULTANCY PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Machinery & Parts from KEEPSAKE ENGINEERING CONSULTANCY PVT. LTD. at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider

Employee Count

18

Establishment

1993

Working Days

Monday To Saturday

GST NO

24AAACK7982Q1ZS

Payment Mode

Cheque

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AAACK7982Q1ZS

Ahmedabad, Gujarat

Product Incharge

Mr. Nilesh Chudasama

Address

2, Meldi Industrial Estate, besides AEC substation, Near Railway Crossing, Gota, Ahmedabad, Gujarat, 382481, India

wheel discs in Ahmedabad

Report incorrect details