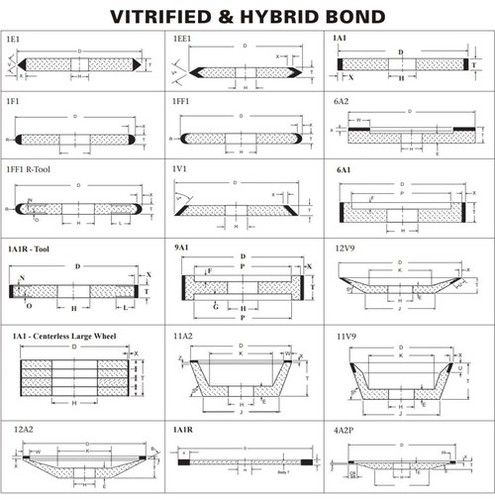

Vitrified And Bond Drawings

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Hybrid Bond |

| Dimensions | Varied |

| Grit Size | Iso Standardized |

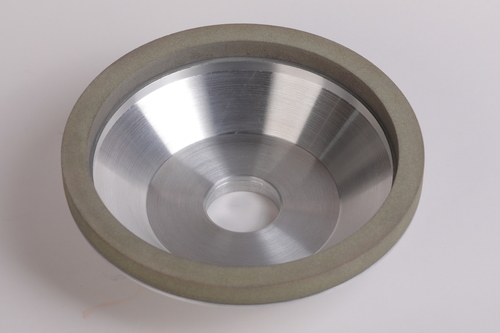

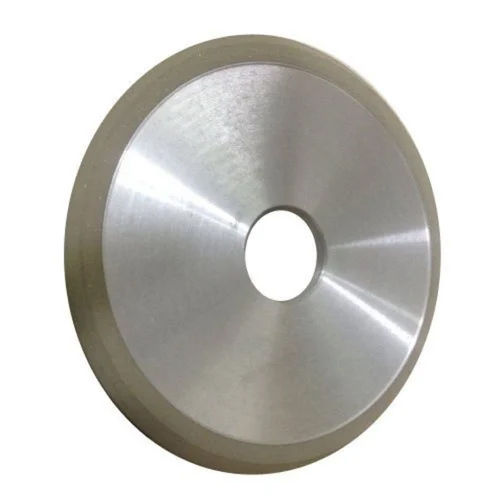

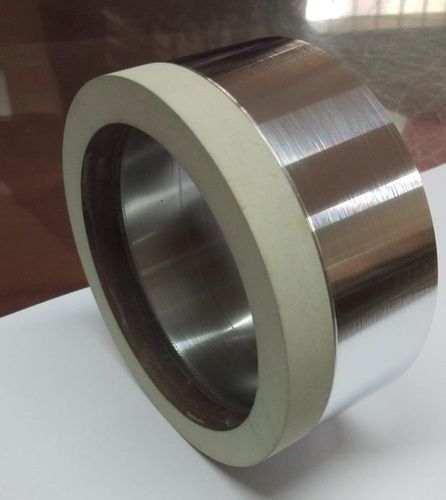

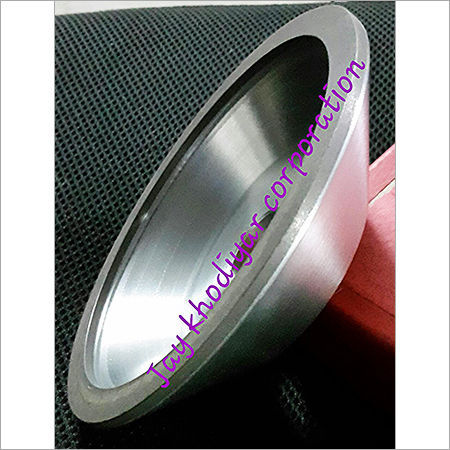

| Shape | Multiple |

| Bond Type | Vitrified/Hybrid |

| Application | Cnc Tool Grinding |

| Accuracy | High |

| Features | Faster Grinding, Less Machine Strain, High Material Removal, Improved Finish, Reduced Cycle Times, Long Wheel Life, High Temperature Stability, Low Power Consumption |

Product Overview

Key Features

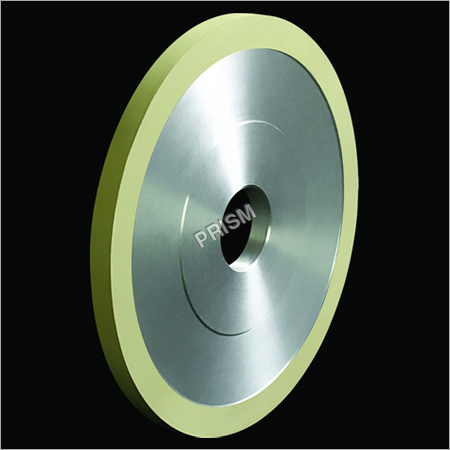

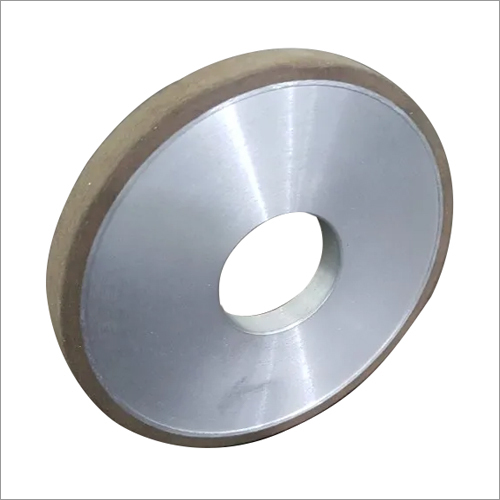

Vitrified and Bond Drawings

We are the leading manufacturer of hybrid diamond wheels, This has put great demands on the Diamond wheel manufacturers to come up with wheels which can grind faster, put less strain on the machine and Job that is being ground

we offers a perfectly matched range of products that allow you to take full advantage of the diamond wheel to manufacture your cutting tools. These wheels are made of a new generation HYBRID bond.

Hybrid Wheels ensure higher material removal without compromising on the surface finish, while ensuring considerable reduction in cycle times. These wheels can be used for both Fresh tool manufacturing and re-sharpening, on CNC Tool and Cutter Grinders.

Properties of the Hybrid Wheels

- Capable of taking higher depth of cuts.

- High lubrication at the point of grinding

- Lesser load on the spindle motor.

- Increased profile retention on the wheel.

- Lower grinding force on the work place, which results in lesser work place deflection during Grinding.

These properties of the Hybrid bond improve the performance of the CNC Tool and Cutter Grinder in the following ways.

- Increased rate of material removal with high temperature stability.

- Reduced grinding time per component

- Low and constant power consumption

- High profile stability and better machine productivity

- Long wheel life and long dressing interval.

| International Standardization of Grit Sizes for Diamond and Cubic Boron Nitride | ||||||||

| Sieve Grit Designations | ||||||||

| Diamond | Boron Nitride | For Comparison: | Nominal Mesh To ISO R 565 1972 | For Comparison | ||||

| FEPA-Standard | FEPA-Standard | US Standard ASTM-E-11-70 Diamond + CBN | DIN 848 June 65 Simplified adaptation to FEPA & Us Adaption | |||||

| Close | Wide | Close | Wide | Close | Wide | um | Close | Wide |

| D 1181 | D 1182 | B 1181 | B 1182 | 16/18 | 16/20 | 1180/1000 | D 1100 | |

| D 1001 | B 1001 | 18/20 | 1000/850 | D 900 | ||||

| D 851 | D 852 | B 851 | B 852 | 20/25 | 20/30 | 850/710 | D 500 | D 700 |

| D 711 | B 711 | 25/30 | 710/600 | D 450 | D 500 D 350 D 250 | |||

| D 601 | D 602 | B 601 | B 602 | 30/35 | 30/40 | 600/500 | ||

| D 501 | B 501 | 35/40 | 500/425 | |||||

| D 426 | D 427 | B 426 | B 427 | 40/45 | 40/50 | 425/355 | ||

| D 356 | B 356 | 45/50 | 355/300 | D 280 | ||||

| D 301 | D 252 | B 301 | B 252 | 50/60 | 300/250 | D 220 | ||

| D 251 | B 251 | 60/70 | 250/212 | |||||

| D 213 | B 213 | 70/80 | 212/180 | D 180 | D 150 | |||

| D 181 | B 181 | 80/100 | 180/150 | D 140 | ||||

| D 151 | B 151 | 100/120 | 150/125 | D 110 | ||||

| D 126 | B 126 | 120/140 | 125/106 | D 90 | D 100 | |||

| D 107 | B 107 | 140/170 | 106/90 | D 65 | ||||

| D 91 | B 91 | 170/200 | 90/75 | |||||

| D 76 | B 76 | 200/230 | 75/63 | D 55 | D 70 | |||

| D 64 | B 64 | 230/270 | 63/53 | D 45 | ||||

| D 54 | B 54 | 270/325 | 53/45 | D 35 | D 50 | |||

| D 46 | B 46 | 325/400 | 45/38 | D 25 | D 30 | |||

Company Details

Focusing on a customer-centric approach, Hindustan Abrasive Technology has a pan-India presence and caters to a huge consumer base throughout the country. Buy Diamond Grinding Wheel in bulk from Hindustan Abrasive Technology at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

15

Establishment

2012

Working Days

Monday To Sunday

Related Products

More Product From This seller

Seller Details

Bhavnagar, Gujarat

Proprietor

Mr. Mehul Patel

Address

Plot No. B-5808/B, Near Vidhyadish Vidhya Sankul, Pramukhswami Nagar, Kaliyabid, Bhavnagar, Gujarat, 364002, India

Diamond Grinding Wheel in Bhavnagar

Report incorrect details