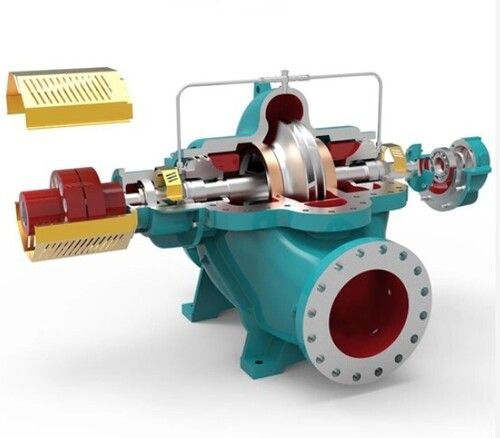

Metal Vertical Axial Flow Pump For Used In Large-scale Water Conservancy Projects

Price:

Get Latest Price

In Stock

Product Specifications

| Color | Green and White |

| Usage | Industrial |

| Material | Metal |

| Structure | Vertical Axial Flow Pump |

| Power | Electric |

| FOB Port | shanghai |

| Payment Terms | Others, Letter of Credit (L/C), Cash in Advance (CID), Cash Advance (CA) |

| Supply Ability | 3000 Per Year |

| Delivery Time | 120 Days |

| Main Domestic Market | All India |

Product Overview

Key Features

This series of products can be used for clean water or other liquids with physical and chemical properties close to water whose temperature of conveying medium is no more than 50a .

They are widely used in large-scale water conservancy projects, farmland irrigation,industrial conveying water,The thermal power station carries circulating water, shipyard level,urban water supply and drainage and water diversion projects

Working condition

a A The medium:clear water,rain water,river water,sewage waste water,any of various liquids whose physicochemical properties resemble those of water

a A Medium temperature: a 50a

a A Running mode: power frequency or frequency conversion

a Direction of rotation:from the drive end,the pump is rotated in clockwise

a Installation:vertical single foundation,vertical double foundation

Structure advantages

1.Guide bearding

a Standard with high quality rubber guide bearings with small friction coefficient, vibration absorption and especially suitable for axial flow pump

a The lower guide bearing adopts lengthened structure with better length-diameter ratio, which greatly improves the stability of rotor parts;

a Designed with enough lubricating flume,and good cooling lubrication effect

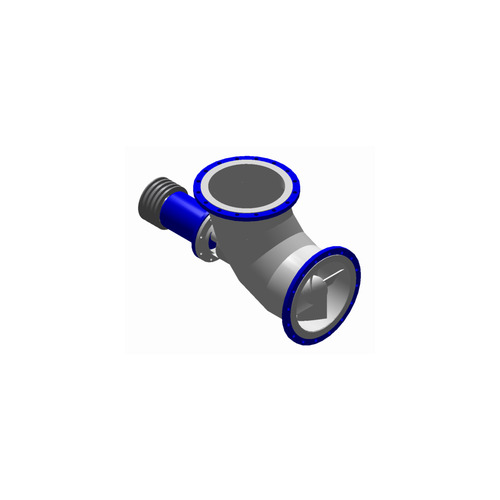

2.Outlet bending tube

a Precision casting,reasonable radius of curvature,internal passage smooth transition,performance optimization

a The design of the multi-rib structure increases the strength and the rigidity of the body

a Reasonable hoisting hole design,convenient hoisting

3.Impeller chamber

a Precision casting,internal passage smooth transition,performance optimization

a Half structure for easy maintenance

4.Thrust bearding unit

a Under conventional working condition,the heat radiation rib of the outer circle radiates heat,so that the external water receiving difficulty in the field is solved

a Under special working conditions,increase the heat radiation of the coil to ensure that the unit runs for a long time

a Equipped with on-line vibration measurement and temperature measurement device to ensure safe running

5.Principal shaft

a Standard steel for high strength shaft,high strength,good rigidity,high critical speed,ensure reliable operation

a And the part matched with guide bearing and packing is provided with removable protective sleeve, with convenient maintenance

6.Impeller

a The 3-D flow theory design and CFD computational simulation are adopted,with high efficiency and wide high-efficiency zone,and good cavitation performance

a Independently developed hydraulic model,high efficiency area is wide

a Adopt metal mould,precision casting

Company Details

Business Type

Exporter, Manufacturer

Employee Count

4000

Establishment

2000

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Changsha, Hunan

Sophia

Address

No.9 Jiuhua Road, Jiuhua Eco-tec Development Area, Yuhu District, Changsha, Hunan, 411104, China

axial flow pumps in Changsha

Report incorrect details