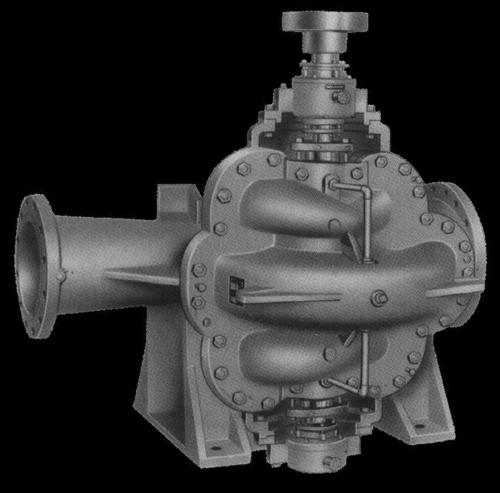

Single Stage Double Suction Centrifugal Pump - Cast Iron Inlet 125-900mm Flow Rate 95-9000m3/h | Superior Mechanical Seal High Efficiency Double-volute Design Online Vibration Monitoring

Price:

Get Latest Price

In Stock

Product Specifications

| Caliber | 125-900 |

| Head Size | 6-205 |

| Flow Rate | 95-9000 |

| Color | Mix |

| Theory | Centrifugal Pump |

| Size | Standard and Customize Size |

| Usage | Pumping Works |

| Material | cast iron |

| Structure | Single Stage Pump |

| Power | Electric |

| Standard | Standard |

| Pressure | Medium Pressure |

| Suction Type | double suction |

| Seals Type | Machinery Seal |

| FOB Port | shanghai |

| Payment Terms | Letter of Credit (L/C) Telegraphic Transfer (T/T) |

| Supply Ability | 3000 Per Year |

| Delivery Time | 60 Days |

| Main Export Market(s) | Western Europe Middle East Africa Asia |

Product Overview

Key Features

a A Capacityi 95~9000m3/h

a A Headi 6~205m

a A Temperaturei a 80a i cooling structure will be adopted for bearing the material of casing & cover is QT500-7a 150a

a A Speedi 740~2970r/min

a A Inlet diameteri 125~900mm

a A Outlet diameteri 80~900mm

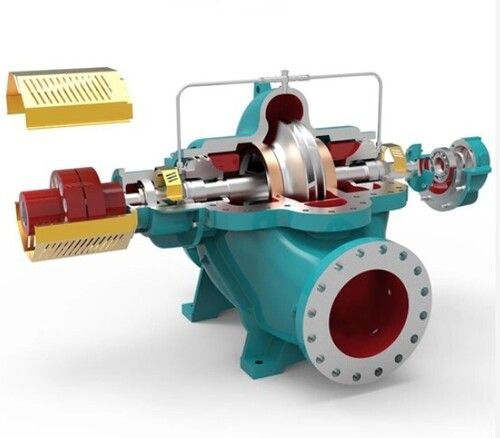

Structural feature

1.Sealing

a Superior mechanical seallong term operation without leakage

a Mechanical sealstrong interchangeability for universal use by non-asbestos soft packing structure and injection type packing structure

a Stainless steel shaft sleeve for easy maintenance

a Half packing glandlarge space for packing replacement

2.Protective cover

a Half-split structurecomply with IE standardsafe and reliable

A

3.Casing

a Circular pressure chamber design with high efficiency

a Double-volute pumping chamber is with balanced radial force and sound strength; bearing and seal are with small force withstanding and long service life

a Water suction chamber is with split rib design;inlet is without vortex and noise while with stable operation and sound cavitation performance

a The inlet and outlet water channels are coated with smooth wear-resistant coatingand water loss is small

a Auto-correct pump cover for easy installation

a Inlet DNa 500 for universal use by vertical and horizontal types

A

4.Bearing

a Short span and enlarged diameter design stable operation and long service life.

a Grease lubrication with small and medium pumponline refueling

a Provided with online vibration and temperature measuring devices to ensure safety operation

a Transfer high temperature liquidemploy water-cooling structure

A

5.Shaft

a Bold designuniversal use for 50HZ and 60HZ pump shaftsound rigidity and stable operation

a Full sealing design no contact with liquid and easy maintenance

a Allow short-time inversion common shaft for forward and reverse rotations

6.Impeller

a Three-dimensional flow theory design employedCFD calculation simulationhigh efficiency high efficiency zone width and sound cavitation performance

a Provided with modified impeller;comprehensive performance curve is full and wide.

Company Details

Business Type

Exporter, Manufacturer

Employee Count

4000

Establishment

2000

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Changsha, Hunan

Sophia

Address

No.9 Jiuhua Road Jiuhua Eco-tec Development Area Yuhu District Changsha Hunan 411104 China

Report incorrect details