Vertical 2d Fsw Equipment Purity(%): 99%

Price:

Get Latest Price

In Stock

Product Specifications

| Color | Red |

| Structure | Vertical |

| X-axis speed | 5-1000mm/min |

| Max thickness | 6mm |

| Control system | Siemens NC |

| Machine size | 2500*2300*3050mm |

| Table size | 600*800mm |

| Features | Precise Welding, Long lifespan, High Accuracy, Strong build, Fast Speed, Easy Operation, Versatile, Cost-effective |

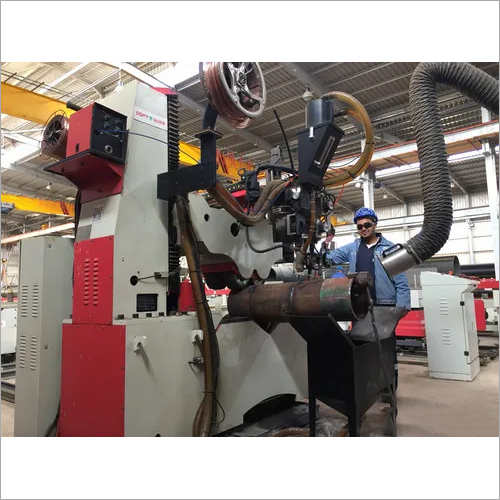

Product Overview

Key Features

Since

1921, we are engaged in captivating the needs of the clients by

offering a qualitative range of

Vertical

2D FSW Equipment.

The provided equipment is precisely manufactured by making use of

supreme class components and the latest technology in compliance with

predefined industry norms under the guidance of veteran

professionals. This equipment is used for all electric connections of

welding spindle, unstrained rotation. Apart from that, this Vertical

2D FSW Equipment

is available to the clients at nominal prices.

Features:

Equipped with

excellent quality hydraulic components & sophisticated control

systems

Manufactured with the

best quality components which enhance its longer functional life

Strong construction

ensures hassle-free working

Fitted with motor to

enhance its working speed

Model | HT-JL6*6/2 | ||

Structural Type | Vertical Structure | X-axis Speed | 5-1000mm/min |

Max Thickness | 6mm | Y-axis Speed | 5-1000mm/min |

X-axis transverse | 0-600mm | Z-axis Speed | 5-500mm/min |

Y-axis cross | 0-400mm | C axis | n*360 degree CNC |

Z-axis Plunge | 0-500mm | A- axis adjustment | 0-5 degree Manual |

Machine size | 2500*2300*3050mm | Control System | Siemens NC System |

Table size | 600*800mm | Keyhole Removal Technique | Non-exithole welding technique |

Equipment Features:

Servo control method is used, resulting in higher accuracy of tool pin withdrawal control and steady weld quality;

Faster system response and transfer rate, higher control accuracy, stronger anti-jamming ability and higher system reliability are achieved;

Slip ring devices are employed for all electric connections of welding spindle, unstrained rotation of C axis is allowed, and continuous welding of complex curves is realized.

Company Details

Focusing on a customer-centric approach, Shanghai Aerospace Equipments Manufacturer has a pan-India presence and caters to a huge consumer base throughout the country. Buy Welding Equipment in bulk from Shanghai Aerospace Equipments Manufacturer at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

1580

Establishment

1921

Working Days

Monday To Sunday

Related Products

More Product From This seller

Seller Details

Shanghai, Shanghai

International Sales Engineer

Ms. Kelly Li

Address

100, Huaning Road, Minhang District, Shanghai, Shanghai, 200245, China

Welding Equipment in Shanghai

Report incorrect details