Total Cam Solution

Price:

Get Latest Price

In Stock

Product Specifications

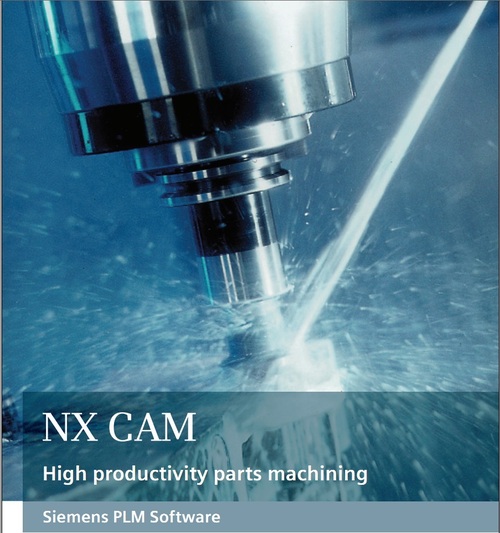

| Software Type | CAM |

| Machining Capabilities | 2-axis, 3-axis, 5-axis |

| Geometry Support | Prismatic, complex |

| Materials Support | Metals, composites |

| Finishing Methods | Roughing, finishing |

| Usage | CNC machining simulations, toolpath generation, and automated cutting methods for aerospace, automotive, and other industries. |

| Compatibility | NX CAM |

| Features | Automated machining, High-speed machining, Multi-axis support, Superior surface finish, Collision detection, Cost reduction, Time reduction |

Product Overview

Key Features

Owing

to the expertise of our professionals, we have been engaged in

offering Total CAM Solution. Our professionals hold

immense experience in this domain and ensure to deliver exact

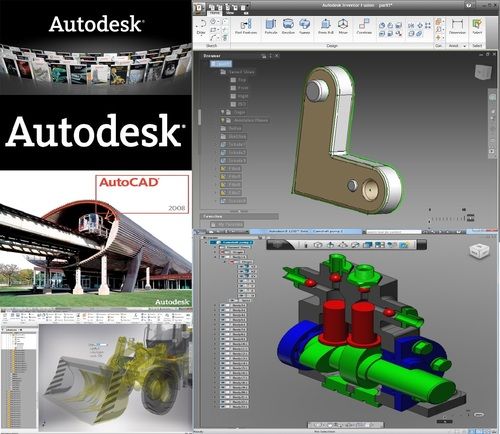

solutions to the clients. Further, our professionals provides 2-axis

and 3-axis machining capabilities for prismatic and parts ranging

from editing to advanced, manual tool path creation and, automated

cutting methods. Our professionals can design all the parts, tools and

equipment in 2D sketching and then convert it into advanced 3D

models. We offer this Total CAM Solution at very

reasonable rate to the clients.

Solutions:

Optimized roughing methods maximize the material removal rate without overloading the tool.

Fully automated rest milling removes uncut material from previous operations and eliminates air-cutting.

Wide range of finishing techniques deliver superior surface finish quality.

Automatic collision detection ensures safe machining of the most demanding geometry.

High-speed machining

Successful high-speed roughing in NX maintains high metal removal rates while managing tool loads.

HSM finishing operations, such as the Streamline feature, produce smooth flowing cutting patterns that result in fine finishes at high feed rates.

5-axis machining

Multiple-axis machining in NX enables you to produce precision complex parts with fewer operations and setups reducing cost and delivery times. NX CAM supports a range of methods for defining precisely controlled multi-axis tool paths on complex surfaces, with effective collision and gouge checking.

Fast and accurate roughing and finishing methods facilitate machining of complex parts, such as those typically machined for the aerospace industry.

Z-level method with tilted tool facilitates the use of of shorter tools to reduce tool deflection.

Smooth flowing Streamline strategy is an ideal cutting method for multi-axis HSM finishing.

Curvature matching technology with a continuously adjusted tool axis maximizestool contact to facilitate fewer passes with larger tools

Automatic variable-axis profiling requires only minimum geometry selection to cut along drafted walls and other profiles.

Turning

NX CAM providesa complete turning solution that is easy enough to use on simple programs and capable enough to tackle your toughest geometry in multi- spindle, multi-turret applications. Turning in NX can use either 2D part profiles or full solid models. It includes routines for roughing, multiple-pass finishing, grooving, thread cutting and centerline drilling. NX turning enables A-axis and B-axis tool control. In addition to rich functionality for common tasks, a special A teach mode capability provides extra user control for fine finishing and special cutting situations.

Multi-function machines

NX offers a complete range of machining capabilities for the latest multi-function machines that support simultaneous multi axis operations. Using a graphical display the Synchronization Manager provides interactive control for machining sequences across multiple channels. Keeping track of the in-process state of the workpiece is a critical component of effective mill-turning. NX CAM automatically generates an in-process workpiece (IPW) to provide seamless transfer of workpiece configurations between milling and turning.

Company Details

Focusing on a customer-centric approach, 3D TECHNOLOGIES has a pan-India presence and caters to a huge consumer base throughout the country. Get CAD CAM Design Services from 3D TECHNOLOGIES at Trade India quality-assured services.

Business Type

Service Provider, Distributor, Supplier

Employee Count

10

Establishment

2008

Working Days

Monday To Sunday

GST NO

24AJVPG7957J1ZG

Payment Mode

Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Paypal

More Product From This seller

Seller Details

GST - 24AJVPG7957J1ZG

Ahmedabad, Gujarat

Accepts only Domestic inquiries

Proprietor

Mr. Krishna Shah

Address

125-126, 1st Floor, Amc Building, Virat Nagar Cross Road, Virat Nagar, Nh No.: 8, Odhav, Ahmedabad, Gujarat, 382415, India

Report incorrect details