Nx Design Solutions

Price:

Get Latest Price

In Stock

Product Specifications

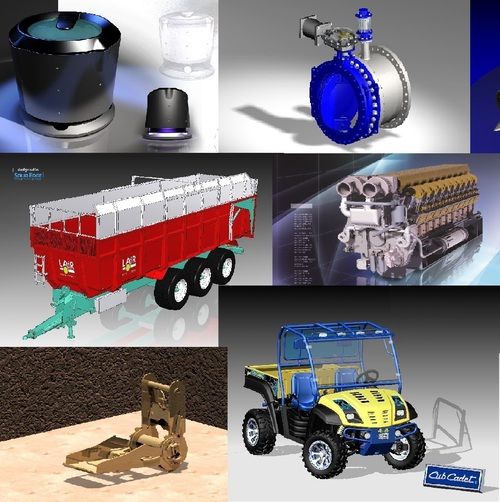

| Software Type | CAD/CAM/CAE |

| Primary Color | Blue |

| Platform Support | Windows |

| Version | Multiple |

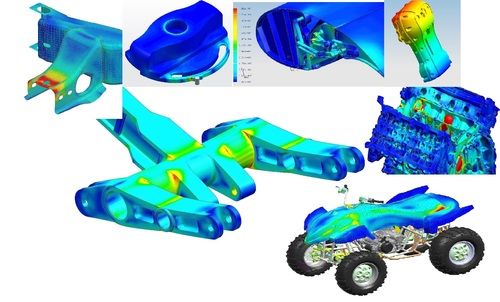

| Modules | CAD, CAM, CAE, PDM |

| Usage | Product design and development, simulations, manufacturing |

| License Type | Subscription |

| Features | CAD design, CAM simulation, Improved efficiency, Streamlined process, Faster design, Enhanced productivity |

Product Overview

Key Features

The NX suite of solutions enables you to transform your entire product development process as well as streamline the efficiency of the individual steps that comprise this process. NX provides best-in-class functionality for CAD, CAM, CAE and PDM for all of your product development initiatives.

Create distinctive designs where style, aesthetic appearance, or quality of form is a key market differentiator

Consider styling, functionality, manufacturability and affordability throughout an iterative design process

Rapidly evaluate design concepts through photorealistic images and virtual prototypes

Eliminate disconnect between your design/styling teams and the rest of your product development organization

Design what you want and how you want it without the constraints of standalone design tool.

Reverse engineering.NX highly flexible approach to reverse engineering speeds development of the initial design concept.

NX tools can generate a CAD model from scanned physical objects by mapping surfaces and curves to the polygon mesh.

Designers can use NX analysis and rendering tools to rapidly evaluate the imported scan data. Full design completion.NX has all of the tools and integration required to facilitate full design completion. NX enables you to take the concept model directly into product engineering, including into detailed design, simulation, tooling and machining.

The following advanced NX design, simulation and manufacturing capabilities drive these solutions.

Mold design,including NX molded part validation, core/cavity optimization and mold base design capabilities

Progressive die design,including NX part preparation, process design and die structure design capabilities

Stamping design,including NX formability analysis, die planning, die face design, detailed die structure design and

die validation capabilities.

Fixture design,including NX fully associative component design, assembly positioning and mating, kinematic simulation, performance validation and component knowledge library capabilities

CAM integration,including capabilities for integrating NX CAM into your tool design solution to automate your downstream manufacturing definition

Electrode design,including best practices and automated processes you can use to model and design electrodes for any tool project that requires electrode discharge machining (EDM)

Engineering process management,including Teamcenter capabilities you can use to bring all of your product, part, tool, design, manufacturing and CAD data into a single source of knowledge, as well as to establish concurrent design processes for a comprehensive part manufacturing environment.

Company Details

Focusing on a customer-centric approach, 3D TECHNOLOGIES has a pan-India presence and caters to a huge consumer base throughout the country. Get CAD CAM Design Services from 3D TECHNOLOGIES at Trade India quality-assured services.

Business Type

Service Provider, Distributor, Supplier

Employee Count

10

Establishment

2008

Working Days

Monday To Sunday

GST NO

24AJVPG7957J1ZG

Payment Mode

Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Paypal

More Product From This seller

Seller Details

GST - 24AJVPG7957J1ZG

Ahmedabad, Gujarat

Accepts only Domestic inquiries

Proprietor

Mr. Krishna Shah

Address

125-126, 1st Floor, Amc Building, Virat Nagar Cross Road, Virat Nagar, Nh No.: 8, Odhav, Ahmedabad, Gujarat, 382415, India

Report incorrect details