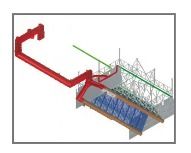

Shell And Tube Heat Exchangers - New, High-efficiency Silver Heat Recovery Systems For Optimal Rankine Cycle Performance, Reduced Energy Consumption And Environmental Impact

Price:

Get Latest Price

In Stock

Product Specifications

| Condition | New |

| Product Type | Shell and Tube Heat Exchangers |

| Color | Silver |

| Main Export Market(s) | Western Europe |

| Delivery Time | 1 Seconds |

| Supply Ability | 1 Per Day |

| GSTIN | 0% |

Product Overview

Key Features

Company Details

Kelvion is a global manufacturer of industrial heat exchangers for a wide range of market segments. The company has been manufacturing and distributing its products in various markets since 1920, and has been operating under the new Kelvion brand since November 2015. Kelvion is the worlds leading specialist in the development and manufacture of industrial heat exchangers. The company is committed to promoting sustainability through innovative heat exchanger solutions and ensuring reliable, efficient and future-proof plant operation.

The extensive portfolio includes heat exchangers for data centres, blockchain technology, hydrogen production, heat pumps, marine, HVAC, refrigeration, the food and beverage industry, and more. With a global sales, service and production network, the company provides reliable and local support to customers all over the world.

From commissioning and on-site services to replacement, Kelvions comprehensive service offering is designed to optimise performance and extend the product life cycle to ensure sustainability and reliability.

Kelvion - Experts in Heat Exchange.

Business Type

Distributor

Employee Count

6000

Establishment

1920

Working Days

Monday To Friday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Pune, Maharashtra

Marketing Manager

Mr Kelvion Info

Address

Plot No. A 31/32, Phase 04, Chakan Midc, Pune, Maharashtra, 411001, India

shell tube heat exchanger in Pune

Report incorrect details