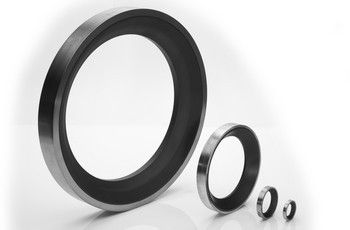

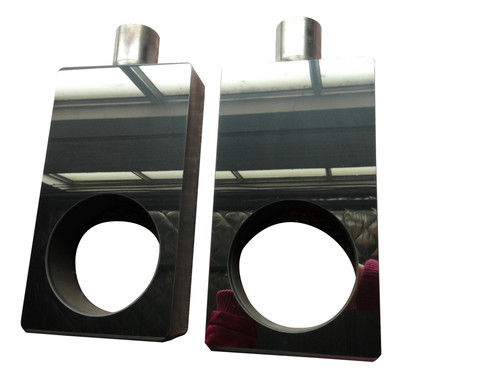

Stainless Steel Valve Seat

Price:

Get Latest Price

In Stock

Product Specifications

| FOB Port | shanghai |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T) |

| Supply Ability | 40000 sets Per Year |

| Delivery Time | 60 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | wooden case |

| Main Export Market(s) | Middle East, Central America, Eastern Europe, South America, North America |

| Main Domestic Market | All India |

Product Overview

Key Features

Valve Seat: The detachable surface parts in valve are used to support the valve spool in the fully closed position and constitute a sealed part. Generally, valve seat diameter is the maximum flow diameter of the valve.

Product Parameters:

Brief Introduction:

The definition of thermal spraying technology in the national standard GB/T18719-2002 "Thermal spraying terminology, classification": The thermal spraying technology uses a heat source to heat the spray material to a dissolved or semi-dissolved state, and spray deposited at a certain speed to after pretreatment of substrate surface coating method. Thermal spraying technology is to create a special working surface on the surface of ordinary materials, it can achieve: a variety of functions such as anti-corrosion, wear-resisting, anti-friction, high temperature resistance, oxidation resistance, heat insulation, insulation, electrical conduction, anti-microwave radiation, etc, through this technology, the goal of saving materials and saving energy is achieved,this tungsten carbide valve seats. We call this special work surface a coating, and the working method for making this coating is called thermal spraying. Thermal spray technology is one of the important components of surface process technology, which accounts for about one-third of surface engineering technology.

Characteristics:

1. The device is simple in structure and flexible in operation. This technology can be used for large-area spraying of large components or for spraying at specified locations; The operation process can be carried out in the factory room or on the outdoor site.

2. Flexible process and less operating procedures, it can quickly repair defects and reduce processing time.

3. Well-adapted, the operation process is generally not limited by the size of the work place and the location.

4. The thickness of the coating can be controlled

5.Besides spray welding, when the substrate heating temperature is low and the workpiece deformation is small, the metallographic structure and performance change are also small.

6. Parts suitable for various base materials

Technical advantages

1. The toughness and easy processing of metal materials can be organically combined with the high temperature resistance, abrasive resistance and corrosion resistance of the ceramic material.

2. A reasonably selected coating material and a suitable spray coating process can provide a surface strengthening coating with various functions.

3. Free from matrix limitations.

The base material used for thermal spraying may be an inorganic material such as metal, ceramic, cement, refractory material, stone, gypsum or the like, it can also be organic materials such as plastic, rubber, wood, and paper etc.

4. Not limited by the size of the work place and the location.

5. The deposition rate of the coating is fast, the thickness is controllable, and the process is simple.

6. The ceramic coating has good processability and the coating can be re-sprayed after the coating is damaged.

Company Details

Business Type

Supplier

Employee Count

39

Establishment

2011

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Suzhou, Jiangsu Sheng

Aaron

Address

Linhu Cailian Industrial Park, Wuzhong District, Suzhou, Jiangsu Sheng, 215105, China

Report incorrect details