Sinter Crusher

Price:

Get Latest Price

In Stock

Product Specifications

| Material | High-Grade Steel |

| Drive | Electro-Mechanical/Hydraulic |

| Bearings | Spherical Roller |

| Roll Configuration | Single/Double |

| Protection | Hard Facing |

| Lubrication | Labyrinth Seals |

| Size | Variable |

| Features | High Capacity, Long Lifetime, Simple Replacement, Low Fines, Gentle Crushing, Durable Design, Easy Maintenance |

Product Overview

Key Features

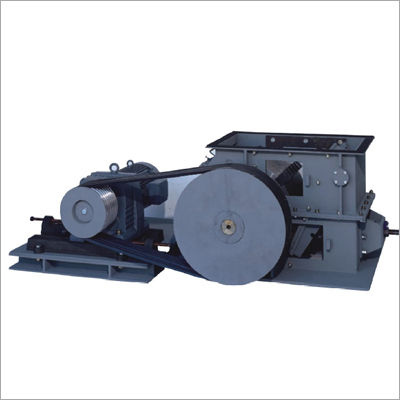

Sinter Crusher

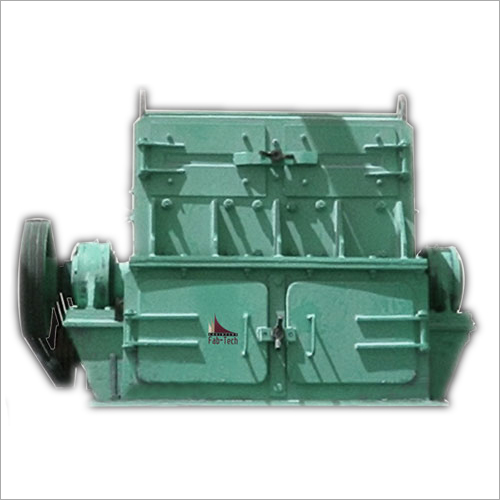

Specially designed Single Roll Crushers are used as Sinte Crushers for primary crushing in the iron and steel industry. Double Roll Crushers are particularly suitable for secondary crushing. Furthermore, they ensure a restricted range of particle size distribution with only a small proportion of tines.

Feed Materials

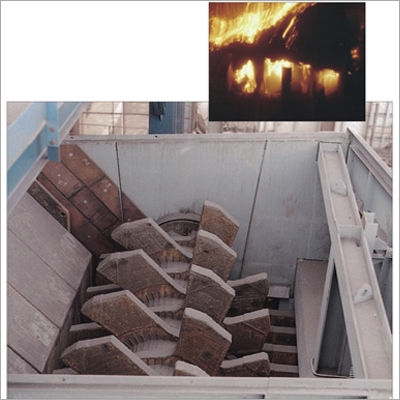

Lumps of hot and cold sinter or primary crushed sinter in sintering plants.

Mode of Operation

The sinter cake of various sizes that are dependent on the sinter belt's width, is fed into the crusher via a feeding table while it is either still hot or already cooled. It is then primary crushed by the crushing teeth on the grizzly bar, For secondary crushing the cooled sinter is fed into the Double Roll Crusher by vibrating feeders while it is distributed over the whole width of the roll. The roll's diameter, the tooth configuration and the circumferential speed are carefully adjusted to the type and the size of sinter in relation to the desired product size. One of the two crushing rolls is desinged as a loose roll in order to influence the product size by adjusting the gap width and to compensate wear and tear.

Advantages

- Consistently high capacity

- High availability long lifetime of components

- Simple replacement of wear and spare parts

- Low proportion of fines gentle crushing method

Special Features

The Primary Sinter Crusher is fitted with a directly driven crushing roll with strong crushing teeth, a movable grizzly bar carrier and a housing with an integral mobile frame to facilitate maintenance.

The feeding table, the crushing tools and bars are protected against wear by hard facing. The crushing roll is arranged onto the machine's base frame. The crusher shaft made of high-grade steel is arranged in amply dimensioned spherical roller bearings. The bearing housings are equipped with lubricated labyrinths to avoid dust and dirt penetration. The crushing roll is electro mechanically driven via electric motor, couplings and gears or it is electrohydraulically driven.

The Double Roll Crusher's individually -driven crushing rolls consist of roller bodies, equipped with crushing rings or shells made out of highly wear-resistant special cast. The crushing roll shafts are arranged in strong steel cast housings with lubricated. amplydimensioned spherical roller bearings with low maintenance requirements. The crushing rolls are driven by electric motors with coupling and gears via V-belt. The base frame is equipped with a positioning device to facilitate maintenance.

Company Details

Focusing on a customer-centric approach, AMBICA CRUSHTECH PRIVATE LIMITED has a pan-India presence and caters to a huge consumer base throughout the country. Buy Construction Machinery in bulk from AMBICA CRUSHTECH PRIVATE LIMITED at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

15

Establishment

1998

Working Days

Monday To Sunday

GST NO

24AABCA6087H1ZQ

Related Products

More Product From This seller

Seller Details

GST - 24AABCA6087H1ZQ

Vadodara, Gujarat

Director

Mr Urmit Hirubhai Patel

Address

987/2, G.I.D.C. Industrial Estate, Makarpura, Vadodara, Gujarat, 390010, India

Construction Machinery in Vadodara

Report incorrect details