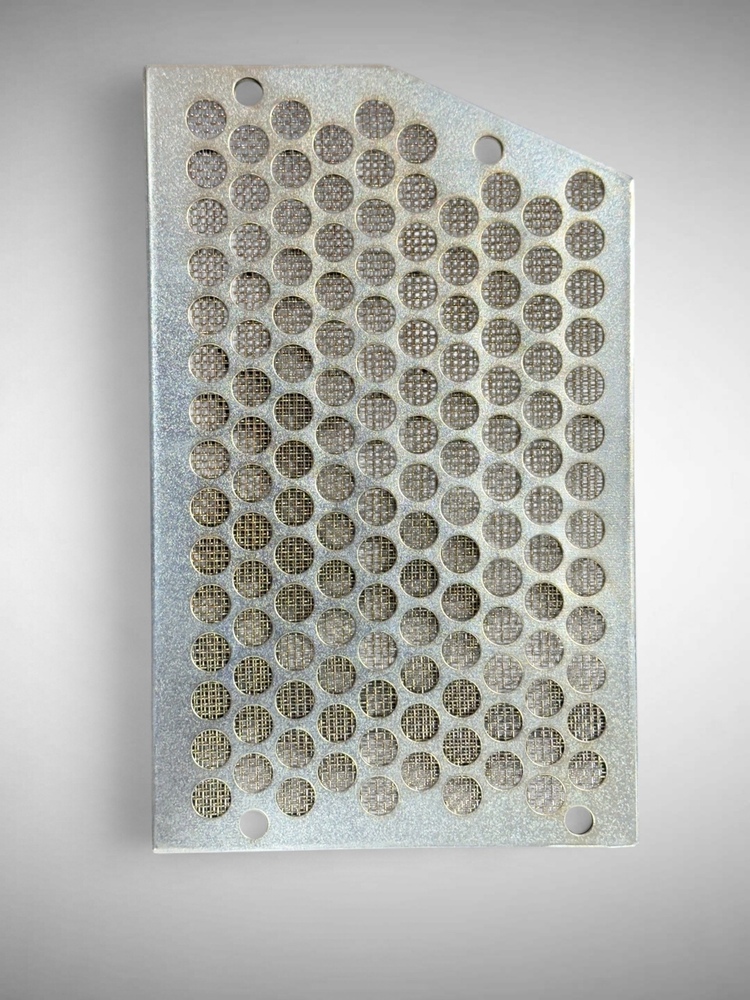

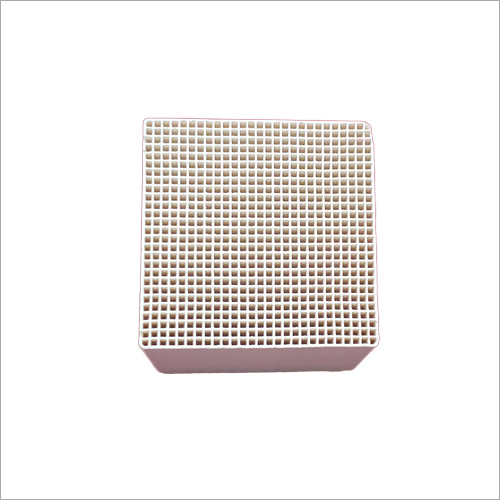

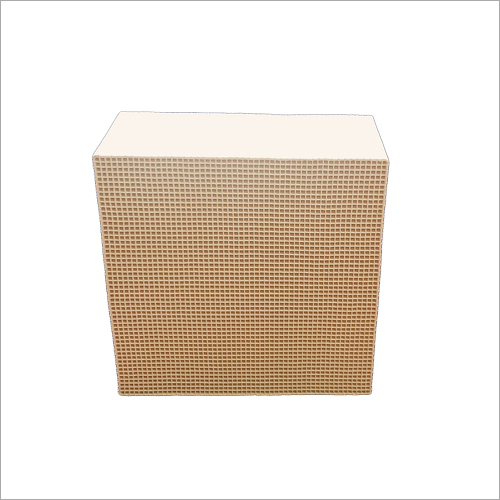

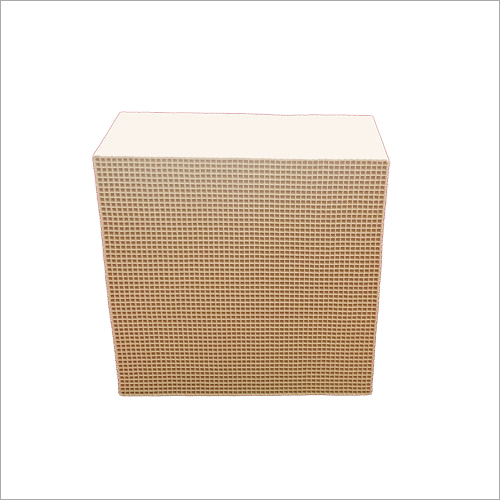

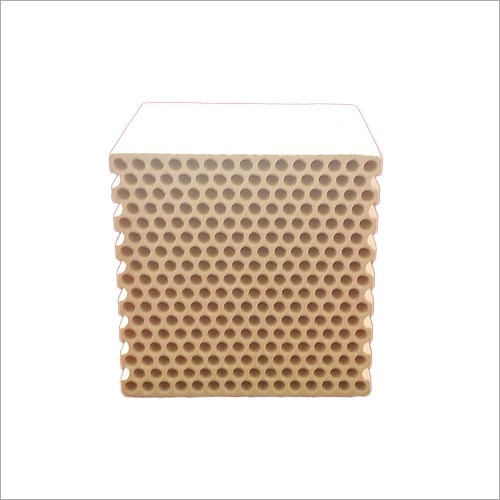

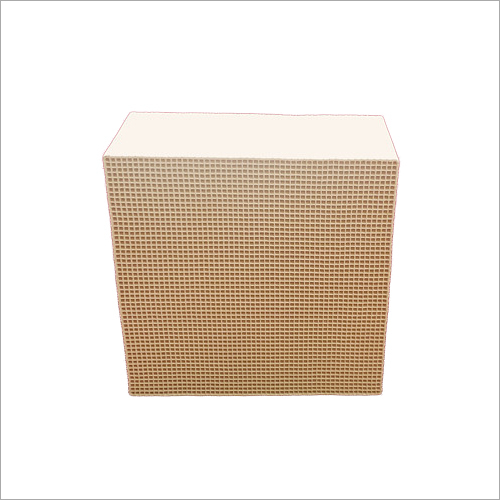

Sic Ceramic Foam Filter Usded As Catalyst Carrier For Diesel Exhaust Purification Diameter: 150*150 Millimeter (Mm)

Price Trend: 5.00 - 50.00 USD / Piece

Get Latest Price

Minimum Order Quantity :

500 Piece

Brand Name :

Sf

In Stock

Product Specifications

| Size | 150 |

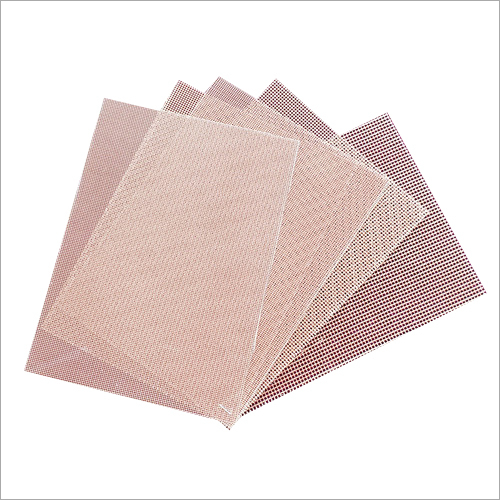

| Pore Size | 10-40ppi |

| Pressure | 0.8 kpa |

| Height | 300 Millimeter (mm) |

| Filter Rating | 2-45kg/s |

| Weight | 5000 Grams (g) |

| Width | 150 Millimeter (mm) |

| Color | grey |

| Outlet Diameter | 150 Millimeter (mm) |

| Filter Media | Polypropylene (PP) |

| Shape | Round |

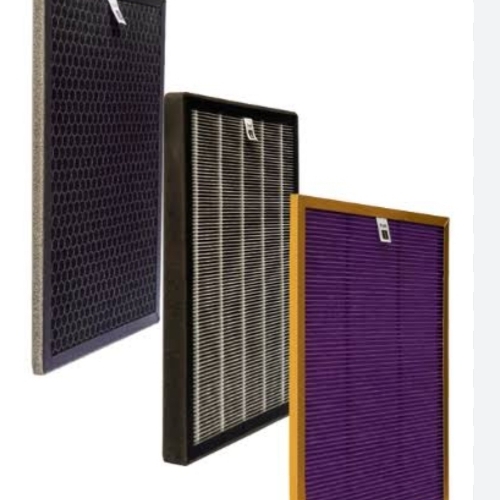

| Usage | air purification |

| Product Type | mass production |

| Length | 300 Millimeter (mm) |

| Inlet Diameter | 150 Millimeter (mm) |

| Material | Other |

| Type | Industrial Depth Filter Cartridge |

| Cartridge Style | Double Open End |

| Diameter | 150*150 Millimeter (mm) |

| Efficiency | 80-90% |

| Application | Air purification |

| Warranty | Three years |

| FOB Port | TIANJIN SHANGHANG ,CHINA |

| Payment Terms | Days after Acceptance (DA), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Western Union, Delivery Point (DP), Telegraphic Transfer (T/T), Cheque |

| Supply Ability | 400000 Per Year |

| Delivery Time | 15-25 Days |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | carton and pallet |

| Main Export Market(s) | South America, Western Europe, Asia, North America, Eastern Europe, Central America, Middle East, Australia, Africa |

| Main Domestic Market | All India |

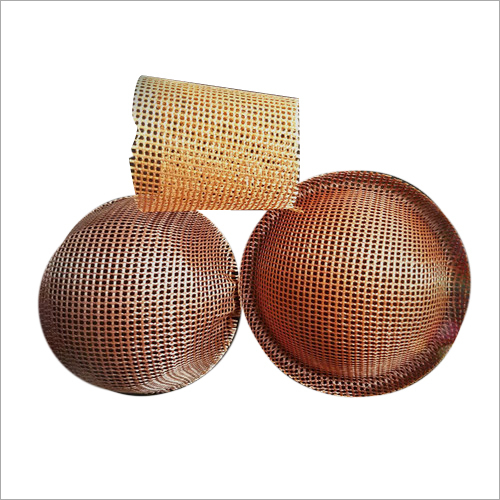

| Certifications | Feature Taking advantage of high thermal conductivity, high strength, and high heat resistance, as well as segmented assembling method, the filter designs are made to withstand high thermal stresses and to be flexible for any shapes.In addition, our SiC-DPF has uniform pore structure because of well controlled raw materials and sintering process. This allows to trap PM in consistent manner, thus enabling stable regeneration (incineration of PM).1.Filtration efficiency more than 99%Our sintering process employs re-crystallization of SiC particles at a high temperature.Pores of micron meter order are uniformly formed to allow exhaust gas to pass through, facilitating an efficient capturing of PM.High thermal conductivity2.Silicon carbide (SiC) has one of the highest thermal conduction rates among ceramic materials.When used as a main component of a DPF substrate, it burns (recycles) trapped soot efficiently, contributing to a low fuel consumption.3.High strengthSiC has the same crystal structure of and comparable hardness to diamonds.This lends itself to high-durability, high-reliability applications.4.High heat resistanceSiC, with a sublimation point at 2000a,,f or higher, retains its characteristics without melting or becoming deformed under any thermal environment encountered in internal combustion engines.5.High chemical stabilitySiC is also chemically stable, and is hardly soluable even in strong acids such as sulfuric acid and nitric acid.However, reactions may occur under special conditions.6.High shock resistanceWe have reduced fracture stress generated by temperature differences inside DPFs by employing a segmented structure, allowing retention of the DPF shape under any operating condition.Working principle for removing SPM Install the SIC-DPF between the engine and the muffler to remove suspended particulate matter (SPM) in the exhaust gas of the diesel engine. DPF features a honeycomb structure where adjacent gas channels are alternately closed.Because ends are alternately closed on exhaust inlet and outlet ends, exhaust gas is forced to go through filter walls made of SiC, and exiting as a clean gas. |

Product Overview

Key Features

The fine nanoparticels ,inchuding soot ,known as particulate matter(PM),can penetrate deep into our lungs and pose serious health risks ,including aggravated asthma ,lung damage and human carcinogenic effects. Hence in many countries ,stricter exhast emission standards, such as Euro V,are bening set, and a diesel exhaust after-treatment is needed.

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

300

Establishment

2013

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Cangzhou, Hebei

Sales Manager

Ms Kerry

Address

Guanting Industrial Park, Cangzhou City, Hebei Province China, Cangzhou, Hebei, 061034, China

Report incorrect details