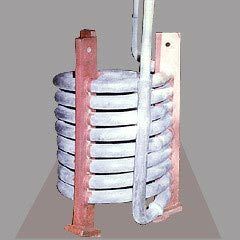

Shell Heat Exchanger By Micro Finish Engineering Co.

Price:

Get Latest Price

In Stock

Product Specifications

| Shell | Mild Steel |

| Tubes | Copper |

| Baffles | Precision Punched |

| Tube Sheets | Carbon Steel |

| End Bonnets | Cast Iron |

| Flow | One, Two |

| Applications | Industrial |

| Features | Robust Design, Corrosion Resistance, Low Maintenance, Maximum Service, Minimum Cost, Quality Material, Precision Machining |

Product Overview

Key Features

With the state-of-the-art the infrastructure facility, we are able to manufacture and supply Shell Heat Exchanger. Cast iron, gun metal and stainless steel are used to fabricate this exchanger. Our offered heat exchanger is designed and developed by a team of experienced professionals, who ensure to provide excellent output. This exchanger is known for its robust construction, abrasion and corrosion resistance and low maintenance. Shell Heat Exchanger is commonly used in marine & industrial applications.

Other details & specifications:

This line of pre-engineered compact heat exchangers is available in fixed tubesheet and removal tube bundle designs, the later with either straight tube or U-tube arrangements. Flow arrangements can be done one, two or four pass. Units are available as commercial, ASME or TEMA C. MFE heat exchangers are designed & manufactured to provide maximum service performance at minimum cost and lead time.

Quality & Reliability :

Reliability comes from using high quality materials in a well conceived design that is properly applied by knowledgeable engineers and manufactured by skilled personnel. MFE utilizes quality, precision machining centers to convert raw materials into high value component parts. Then experienced skilled welders and assemblers transform these components into superior quality finished heat exchangers.

Features

- Shell : Rugged shell available in Mild Steel and Stainless steel. Minimum clearance between shell and baffles reduce by-pass and maximize heat transfer.

- Tubes : Tubes are available in copper, 90:10 Cu-Ni, stainless steel, Admiralty or Titanium. Tubes are roller expanded. Seal welding and grooving available in some cases.

- Baffles : Precision punched baffles assure effective circulation by providing minimum clearance between tube hole and tube.

- Tube sheets : Thick Carbons steel, Stainless steel or 90:10 Cu-Ni tube sheets are welded to shell. Holes are precision drilled for proper fit.

- End Bonnets : End bonnets are of high quality cast iron, gun metal, bronze or stainless steel in 1, 2, 4, 6 or 8 pass configurations. Fabricated heads are available and are standard on TEMA C models. Zinc anodes to neutralize the effect of galvanic action can be furnished on special order.

Company Details

Focusing on a customer-centric approach, MICRO FINISH ENGINEERING CO. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Heat Exchangers in bulk from MICRO FINISH ENGINEERING CO. at Trade India quality-assured products.

Business Type

Manufacturer, Supplier, Trading Company

Employee Count

1217

Establishment

1982

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ahmedabad, Gujarat

Accepts only Domestic inquiries

Marketing Executive

Mr. Pratik Nayan Gosalia

Address

Plot No: 3005, Phase-IV, Opposite Sidhinath Ice Factory, GIDC, Vatva, Ahmedabad, Gujarat, 382445, India

shell tube heat exchanger in Ahmedabad

Report incorrect details