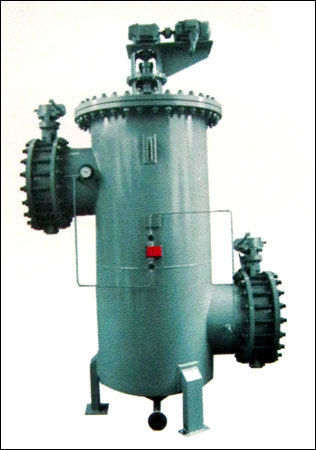

Self Cleaning Strainers - High-efficiency Back Flush Design | Automatic Filtration For High Suspended Solids And Viscous Materials

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Inlet Connection | Tangential |

| Outlet Connection | Tangential |

| Drain | Bottom |

| Pressure Drop | Adjustable |

| Valve Type | Shut Down |

| Element Type | Filtration |

| Features | Auto Cleaning, Process Continuity, High Viscosity, Slurry Filtration, Uninterrupted Filtration |

Product Overview

Key Features

OPERATION

Back wash type self cleaning filters work on a flow direction of outside to inside. Unfiltered fluid enters into filter housing through bottom tangential inlet connection. Contaminants are deposited on the outer surface of filter elements and clean filtrate passes through inside diameter of element and removed through the top tangential outlet. Users can set their differential pressure data within control panel. Once the differential pressure across the system reaches the pre-defined level of pressure drop, inlet and outlet valves shut down and the drain and backwash valves open for defined interval of time. During this process, debris deposited on outer surface of element shall be drained out and collected through bottom drain. This cycle continues as per pre-defined settings and process requirements.

Company Details

Harsha Filters is steadily growing in the industry, since its inception. Based in Bangalore (Karnataka), the company is renowned as an eminent Manufacturer, Exporter, and Supplier of Industrial Filters, Industrial Filter Elements, Filter Cartridges, Pulse Jet Dust Collection System and Industrial Strainers, in India. The products, that we provide, comply with international quality standards and have been proved to be exceptionally efficient and cost effective for the end users. The outstanding performance of our products has gained us a huge clientele from all over India and most parts of the world, such as in Indian Subcontinent, East Asia, Middle East, South East Asia, etc. To cater to the varying demands of the clients, we provide them with customization option. Not only this, our products are delivered to the clients within stipulated timeframe, which helps us in building long-term relationships with the clients.

Business Type

Exporter, Manufacturer, Supplier, Wholesaler, Fabricator

Employee Count

8

Establishment

2010

Working Days

Monday To Sunday

GST NO

29BGLPM9757J1ZE

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 29BGLPM9757J1ZE

Bengaluru, Karnataka

J. Mukunda

Address

No. - 17, Devanahalli Road, Opp. Old Madras Road, Virgo Nagar Post, Bengaluru, Karnataka, 560049, India

water strainer in Bengaluru

Report incorrect details