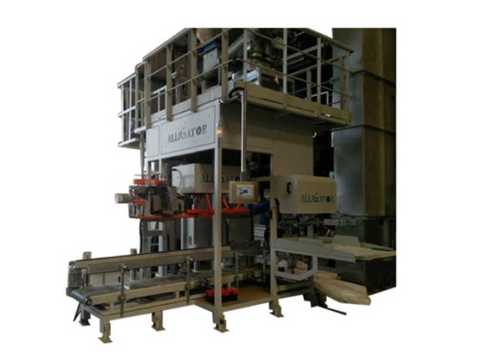

Screw-feed Bagging Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Dimensions | Customizable |

| Power | Variable |

| Capacity | High Volume |

| Weight | Variable |

| Accuracy | High Precision |

| Control | Digital Indicator |

| Features | Automatic Operation, Manual Operation, Easy Cleaning, Versatile Bagging, Easy Maintenance, High Capacity, Precise Weighing, Customizable Design |

Product Overview

Key Features

Features

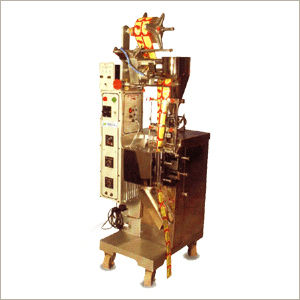

- Automatic and Manual mode.

- Designed to suit open mouth bags.

- Multiple product types can be bagged.

- Easy to clean, easy to maintain.

- System can accommodate different bag sizes using bolt-on fittings.

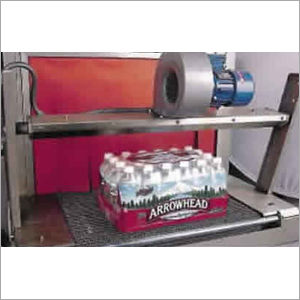

- Easy integration with a conveyor.

- Can be designed as a free-standing (as shown at left) or bolt on to existing supply bin arrangement.

- Up to 100 different product target weights can be stored and recalled using the digital indicator.

- Product in-flight is taken into account.

- Units are built to Customer's requirements, including bin sizes, bin finishes (painted or stainless steel), mounting frame, discharge arrangement, etc.

- Conveyors with VF drive & RFI filter.

- Sewing machines with adjustable stand.

- Check weighers for trade applications.

- Size & finish of all bins to suit Customer requirements.

A dual, net, screw bagging machine is ideally suited to a high volume process factory and for dry, large particle products, such as grain and cotton seed. The bag per minute rate is only limited to the speed at which an operator can fit a bag. As one weigh bin is being discharged, the other is being filled, enabling minimal time lost.

Net bagging machines pre-weigh the product in a separate bin before discharging the product in to the bag.

Typical Operation

- The Operator uses the digital indicator to recall the required target weight (setpoint).

- The Operator initiates the automatic mode.

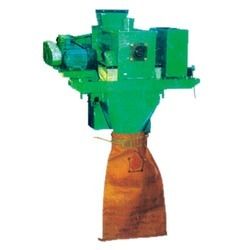

- Screw/auger 1 begins supplying product to weigh bin 1 until the setpoint is reached.

- The Operator fits a bag to the discharge chute and activates the bag clamp.

- When the setpoint of weigh bin 1 is reached, and a bag is fitted to the discharge chute, the product discharges in to the bag.

- When filled, the bag is released, and the operator fits another bag.

- Meanwhile, screw/auger 2 begins supplying product to weigh bin 2 until the setpoint is reached.

- When the setpoint of weigh bin 2 is reached, and a bag is fitted to the discharge chute, the product discharges in to the bag.

- The process is repeated from step 3.

Company Details

Focusing on a customer-centric approach, SHARP PACK MACHINES & EQUIPMENTS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from SHARP PACK MACHINES & EQUIPMENTS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

8

Establishment

1982

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Thane, Maharashtra

Accepts only Domestic inquiries

Proprietor

Mr. Pradip Bholanath Kundu

Address

Office No. 7, Jyoti Industrial Estate-2, Behind Radha Krishna Hotel, Upvan, Thane, Maharashtra, 400606, India

automatic bagging machine in Thane

Report incorrect details