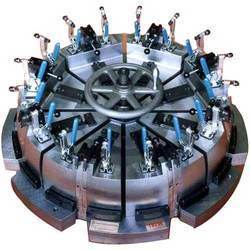

Sand Casting - Mass Limit 2300-2700 Kg, Part Weight 0.075-0.1 Kg | Versatile For Small Batches, Core And Riser Integration, Ideal For Rail Car Fabrication

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Metal Alloys |

| Weight Range | 0.075-2700 Kg |

| Manufacturing Process | Sand Casting |

| Mold Type | Two-Part |

| Accuracy | High |

| Surface Finish | Variable |

| Part Size | Customizable |

| Features | Cost-Effective, Versatile, Durable, Precise, High-Strength, Easy To Fabricate, Mass Production, Small Parts, Large Parts |

Product Overview

Key Features

* Mass limit of 2300-2700 kg

* Minimum part weight ranges from 0.075-0.1 kg

* Can create the entire bed for one rail car

It is the most popular and most basic of all the casting processes along with being economical. first a cavity in the sane is formed by using a pattern made of wood or metal. The cavity is contained in a flask. Cores are put in the cavity to form holes of the desired shapes.

An extra void called Riser is created in the mold to contain excessive molten material. The purpose of this is to prevent voids in the main casting. Generally sand casing consists of a two-part Sand Casting Mold. While the upper part is called the Cope, the lower part is called the Drag. A parting line or surface separates the two.

Some portion of the drag is filled with sand. The cores, core print, and the gating system are placed near the parting line. The cope and the drag are assembled then sand is poured in the cope half. That covers the pattern, core and the gating system.

Company Details

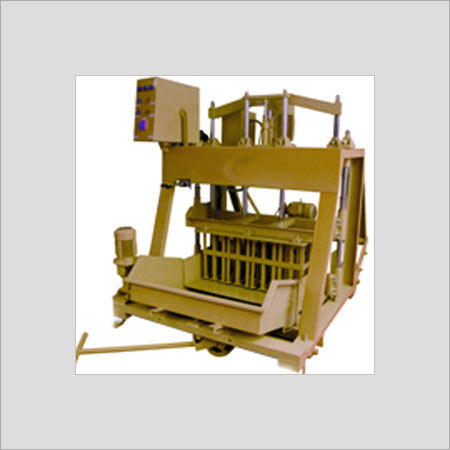

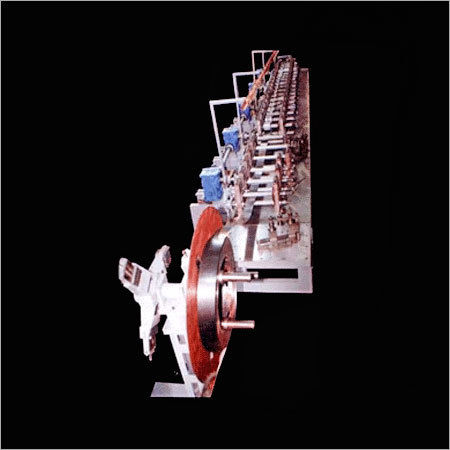

Focusing on a customer-centric approach, Casting India has a pan-India presence and caters to a huge consumer base throughout the country. Buy Roll Forming Machinery in bulk from Casting India at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

13

GST NO

33AAFFC6122Q2ZB

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 33AAFFC6122Q2ZB

Coimbatore, Tamil Nadu

Chief Executive - Operation

Mr. G. T. Bharath

Address

Post Box No. - 5123, No-12, Natesa Gounder Layout-II, Rathinapurai, Coimbatore, Tamil Nadu, 641027, India

castings in Coimbatore

Report incorrect details