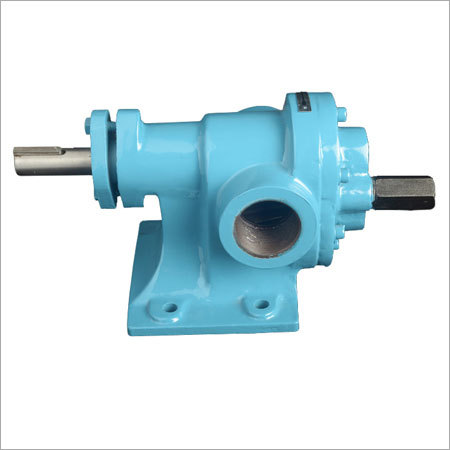

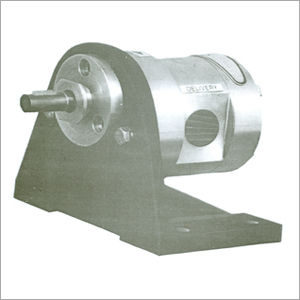

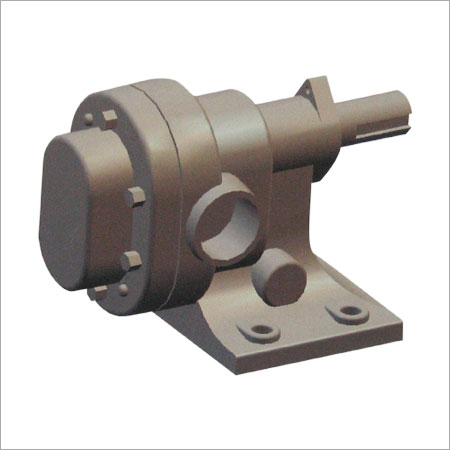

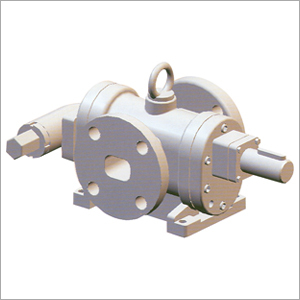

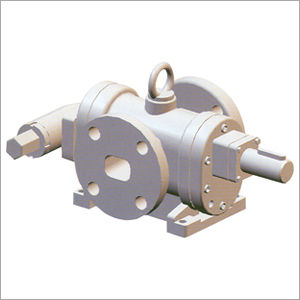

Rotary Twin Gear Pump ( Type Dpms )

Price:

Get Latest Price

In Stock

Product Specifications

| Casing | CF8 |

| Front Cover | CF8 |

| Back Cover | CF8 |

| Rotor Gear | SS-316 |

| Stator Gear | SS-316 |

| Rotor Shaft | En-57/SS410 |

| Stator Shaft | En-57/SS410 |

| Features | Positive pressure, Self priming, SS pump, Adjustable R.V. |

| Packaging Details | Wooden Box Packing. |

| Main Domestic Market | All India |

| Certifications | ISO Certified Co. |

Product Overview

Key Features

General

ROTOJET Rotary gear pump type DPMS is a positive displacement pump with positive pressure characteristic. Rotojet Rotary gear pump type DPMS is all SS pump, specially designed to handle thinner or thicker even corrosive liquid having lesser or no liberating value. ROTOJET rotary gear pump has a self priming capability however some net positive suction head is always required to avoid cavitations depending upon the liquid to be handled & the pump speed

MOC

- Casing CF8

- Front Cover CF8

- Back Cover CF8

- Rotor Gear SS-316

- Stator Gear SS-316

- R.V. Body CF8

- Rotor Shaft En-57/SS410

- Stator Shaft En-57/SS410

- Gland Cover CF8

- Sleeve En-57

- Seal Zpack/PTFE/Mech Seal

- W. Plate LTB/W.M./Grafite

| Pump Model | Capacity At 1440 RPM | Power Req. No Load Viscous H.P. | Pump Dimensions | ||||||||||||||||||||||||

| Port Size | LPM | M3/Hr | US GPM | Over All | Mounting | Shaft | Flange | ||||||||||||||||||||

| 200 CST | 250 CST | 750 CST | A | B | C2 C3 | A1 | B1 | B2 | C4 | D4 | diaD | C | C1 | B3 | B4 | A2 | C5 | R | M | N | G | Wt. Kg. | |||||

| DPMS-050 | S | 13 | 0.75 | 3.30 | 0.75 | 0.11 | 0.20 | 150 | 220 | 130 | 80 | 100 | 75 | 1/2" | 08 | 12 | 80 | 70 | 26 | 38 | 04 | 13 | 4 | 16 | 60 | 89 | 8.5 |

| M | 16.6 | 1.00 | 4.40 | 0.11 | 0.15 | 0.25 | - | ||||||||||||||||||||

| DPMS-100 | S | 30 | 1.80 | 7.92 | 0.15 | 0.30 | 0.42 | 160 | 255 | 135 | 90 | 100 | 90 | 1" | 10 | 15 | 90 | 75 | 29 | 38 | 05 | 18 | 4 | 16 | 79 | 108 | 9.1 |

| M | 37.5 | 2.25 | 9.90 | 0.21 | 0.36 | 0.51 | - | ||||||||||||||||||||

| DPMS-150 | S | 60 | 3.60 | 15.8 | 0.33 | 0.53 | 0.62 | 180 | 300 | 155 | 105 | 130 | 103 | 1 1/2" | 10 | 21 | 100 | 80 | 34 | 45 | 06 | 24 | 4 | 16 | 98 | 127 | 12 |

| M | 75 | 4.50 | 19.8 | 0.40 | 0.67 | 0.76 | - | ||||||||||||||||||||

| DPMS-200 | S | 100 | 6.00 | 26.4 | 0.42 | 0.68 | 0.85 | 200 | 335 | 165 | 110 | 150 | 118 | 2" | 12 | 24 | 112 | 90 | 40 | 55 | 06 | 27 | 4 | 19 | 121 | 152 | 22 |

| M | 125 | 7.50 | 33.0 | 0.51 | 0.85 | 1.05 | - | ||||||||||||||||||||

| DPMS-250 | S | 150 | 9.00 | 40.0 | 0.72 | 0.95 | 1.15 | 220 | 370 | 200 | 130 | 160 | 140 | 2 1/2" | 15 | 28 | 132 | 105 | 40 | 55 | 08 | 31 | 4 | 19 | 140 | 178 | 28 |

| M | 200 | 12.00 | 52.9 | 0.95 | 1.30 | 1.55 | 55 | ||||||||||||||||||||

| DPMS-300 | S | 250 | 15.00 | 66.0 | 0.96 | 1.30 | 1.50 | 235 | 455 | 240 | 160 | 220 | 160 | 3" | 19 | 32 | 160 | 130 | 55 | 75 | 10 | 37 | 4 | 19 | 152 | 190 | 40 |

| M | 333 | 20.00 | 28.0 | 1.25 | 1.75 | 2.00 | 55 | ||||||||||||||||||||

| DPMS-400 | S | 415 | 25.00 | 111.0 | 2.92 | 4.20 | 5.00 | 275 | 530 | 270 | 180 | 270 | 170 | 4" | 19 | 36 | 180 | 145 | 65 | 85 | 10 | 41 | 8 | 19 | 190 | 229 | 69 |

| M | 500 | 30.00 | 132.9 | .350 | 5.0 | 6.00 | 65 | ||||||||||||||||||||

R.V.

Adjustable type Relief Valve facility offered with all model of DPMS series pumps, to rescue the pump and drive by suddenly developed back pressure & also for bypass the flow. Relief Valve is Designed to relieve 100% of capacity with in 10% to 25% of set pressure.

Speed

All model of DPMS series pumps are designed to run at 1440 rpm up to viscosity of 500 Cst however in higher size of above 2" pump speed is required to be reduced with increase in viscosity for consult the work. By reducing the speed the pump shaft should not be loaded with heavy gears or pulley use bearing block to take up such load.

Uses

Rotojet Rotary DPMS series gear pumps are ideally suited for handling thinner liquid at moderate pressuring viz. foam pressurizing application for fire fighting, medium pressure coolant transfer application, light fuel pressurizing application, heavy viscous liquid transfer application such as Molasses, Magma, Soap sock, Tar, Bitumen, Paints, Varnish, Crude, sodal etc.

Future

Double Helical Herringbone gear ensure no side thrust, maintains constant volumetric efficiency over longer period. Modified tooth profile enhances the tooth life, increase volumetric efficiency. Sleeve on shaft make maintenance economical & easy. Extra thick shaft gives higher bearing life, withstands bending effectively.

Company Details

Focusing on a customer-centric approach, P & D PUMPS & GEARS INDUSTRIES has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pumps & Pumping Equipment in bulk from P & D PUMPS & GEARS INDUSTRIES at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

16

Establishment

2007

Working Days

Monday To Sunday

GST NO

24AAJFP2497F1Z3

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AAJFP2497F1Z3

Wadhwan, Gujarat

Accepts only Domestic inquiries

Partner

Mr. Pinakin Patel

Address

Plot No.- 2619, Phase-4, Near Ultra Minerals, GIDC, Wadhwan, Gujarat, 363035, India

rotary gear pump in Wadhwan

Report incorrect details