Roll Shutter Door Forming Machine - Aluminum, Galvalume, Galvanized, 0.3-0.7mm Thickness | 11 Forming Stands, 12 M/min Speed, Siemens Plc Control

Price: 155000.00 INR / Unit

Get Latest Price

Minimum Order Quantity :

1 Unit

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Material | Steel |

| Dimensions | NA |

| Power | 7kW |

| Cutting Tolerance | ±3.0mm |

| Speed | 12m/min |

| Voltage | Customizable |

| Stands | 11 |

| Features | High speed, Durable, Precise, Efficient, Cost-effective, Easy operation, Customizable |

| Price | 155000.00 INR (Approx.) |

| Product Unit | 1 Unit/Units |

| Mop | 1 |

| Stock Quantity | 5 |

| Moq | 1 |

| Packsize | 1 |

| Returnable | No |

| Unit Type | Unit/Units |

| Price Type | fixed |

| Currency | INR |

| Minimum Ordered Packs | 1 |

| Minimum Order Quantity | 1 |

| GSTIN | 0% |

Product Overview

Key Features

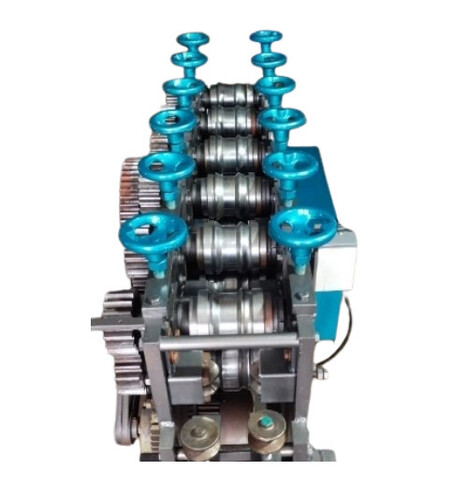

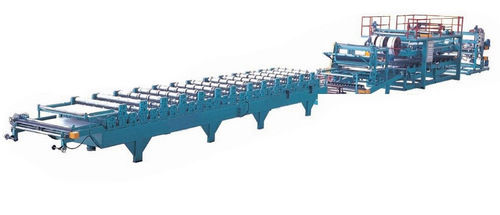

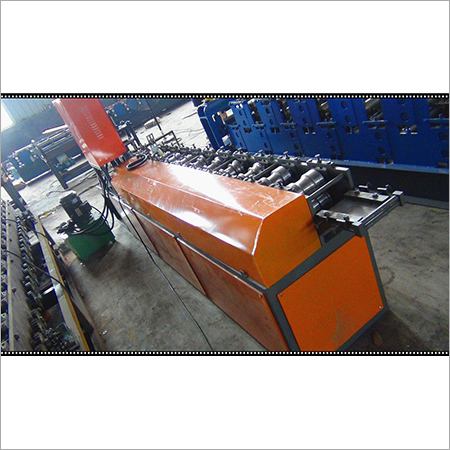

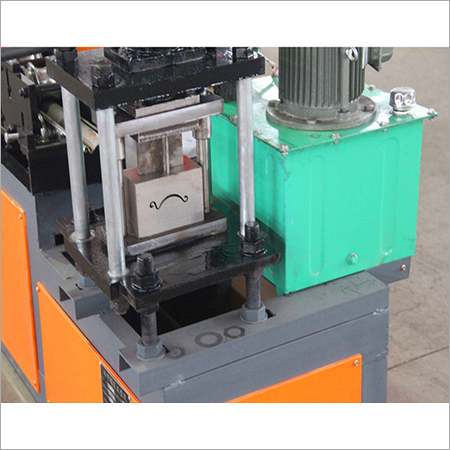

1. Components of roll shutter door forming machine:-

The roll forming machine consists of manual uncoiler, infeed guide, fixed position driven forming stations, cutting equipment, hydraulic station, control console, and manual unload product run out table.

2. Technical Parameters

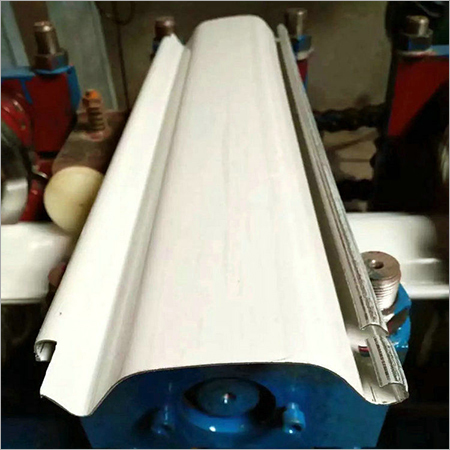

1) Material specification: Aluminum, galvalume, galvanized and pre-painted galvanized steel.

2) Thickness: 0.3 mm to 0.7mm.

3) Main motor power: 4 kw.

4) Hydraulic station power: 3 kw.

5) Feeding width: Depends on the model of profile.

6) Yield stress: 235Mpa(33KSI) ~ 345Mpa (50KSI).

7) Roll forming Speed: 12 m/minute.

8) Cutting Tolerance: +/-2.5mm(lengtha 5000mm); +/-3.0mm(5000mm

10) Coil inner diameter: 508mm.

11) Voltage: As per customera s request.

12) Numbers of stands: 11 stands/stations.

3. Material of Main Equipment

1) Roller Material: High grade No.45 forged steel, coated with hard chrome.

2) Active Shaft Material: High grade No.45 carbon wrought steel, which can improve the integrated mechanic feature of the shaft.

3) Electric Elements: PLC control panel, transducer imported from Siemens, Germany. Other elements are from Schneider Electric, Germany.

4) Cutter Blades: Cr12 mould steel with quenched treatment.

Clients can avail this Roll Shutter Door Forming Machine at industry leading prices from us.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Establishment

2004

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Hangzhou, Zhejiang

Sales Manager

Ms Juliette

Members since

6 Years

Address

Room 2511, Taigu Plaza, Jingcheng Road, Xiaoshan District, Hangzhou, Zhejiang, 311202, China

rolling shutter machine in Hangzhou

Report incorrect details