Refractory Insulation Material Application: Home

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Calcium Silicate |

| Dimensions | Variable |

| Density | 220-280 kg/m³ |

| Compressive Strength | 720 kN/m² |

| Thermal Conductivity | Low |

| Temperature Range | 900-1100°C |

| Service Life | 20+ years |

| Features | High Strength, Energy Saving, Low Conductivity, Long Lifespan, Easy Application, Fire Resistant, Eco-Friendly, Moisture Resistant |

Product Overview

Key Features

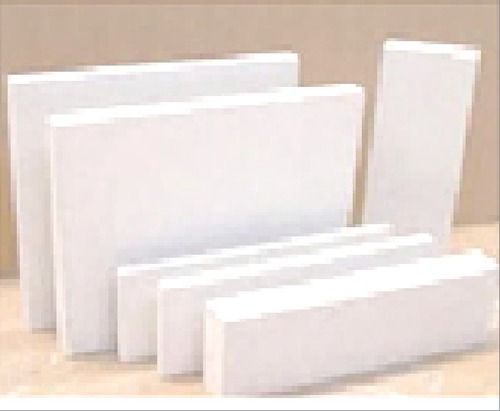

Refractory Insulation Material

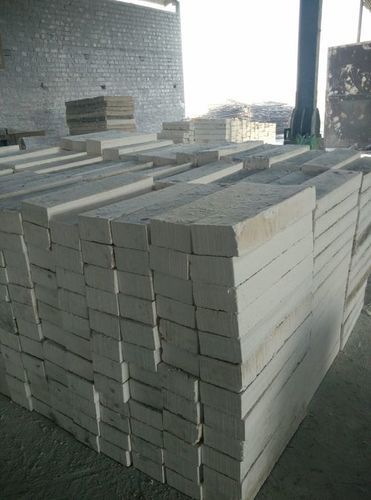

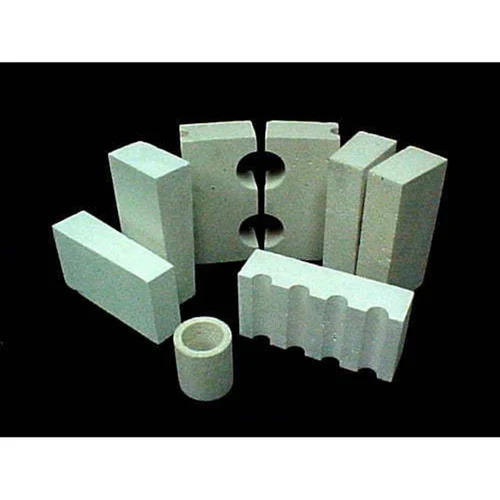

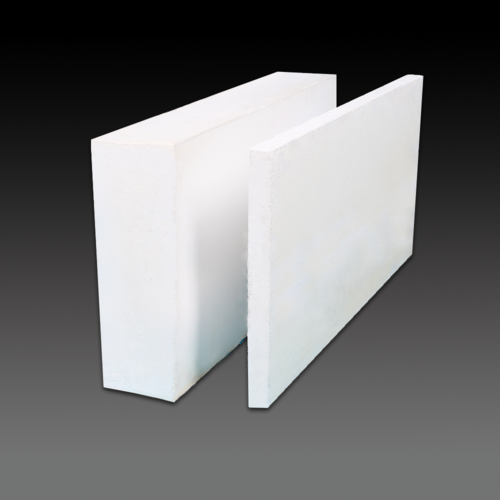

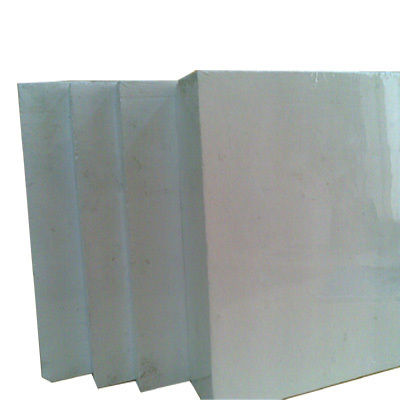

Calsicate is SIR's ground breaking innovation in green industrial building products. Versatile, this product is the ideal thermal insulation solution for a wide range of Refractory Insulation Material. These blocks are made with calcium silicate and can be used for to insulate high-temperature applications like ducts, boilers, steam pipe lines and furnaces among many others. Their high load-bearing capacity makes them ideal for heavy-duty equipment across industries. In addition, Refractory Insulation Material are literally maintenance-free and have a life of more than 20 years.

Their inherent low thermal conductivity provides enormous savings in energy consumption. Enhanced operational efficiencies, lower energy costs and eco-friendliness make Calsicate a revolutinary product in industrial insulation.

Properties

- Strong in intensity: The strongest inorganic thermal insulation material in intensity as compared with other nearest density products.

- Hot-resistant: Not out of shape under the service temperature

- Water-resistant: Strong in intensity wet or dry

- Thermal insulation: The lower thermal conductivity than other hard mass thermal insulation materials.

Uses

Cacium silicate thermal insulation widely be used in Electrical power, Petroleum and chemical industry, Ship-Building, Machining units, Glass industry, and other equipments and pipes of thermal networks in order to conserve energy, reduce the hot-loss, lower the environmental temperature, improve working conditions, raise efficiency. It is main thermal insulation material in industry, such as Boilers, Steam Engines, Steam pipe, Ovens, Distillation tower etc. Moisture resistant thermal insulation material is also used in waterproofing.

Major Applications

- Lining for industrial furnaces(heating furnace, soaking pit, metallurgy industry)

- Cooling machine in cement kiln

- Glass furnace

- Pottery kiln

- Petrochemical industry

- High temperature flue in metallurgy industry

- Power plants

- Shipyards

- Paper mills

- Banking material of refractory bricks

- Electrolyzing cell in nonferrous metal industry

Advantages

- Temperature range 900oC to 1100oC

- Exceptional strength

- Low thermal conductivity

- Easy application: Available sizes and shapes reduce the number of required joints and make

- Calcium silicate easy to work with

- Energy saving: Low thermal conductivity provides significant energy savings.

- Adaptable: Calcium silicate can also be used on a various shapes and sizes of surfaces

- Fire resistant

- Low chloride content

- Asbestos-free

| Properties | IS 9428 1993 limit | Calcium Thermal 950 observed | Calcium thermal 1100 observed |

| Temperature(oC), max, service temperature oC | 950 | 950 | 1100 |

| Bulk Density (kg/m3), day | 220-280+10% | 256 | 270 |

| Compressive strength, reduction in thickness Not to exceed under a load of Dry, 415kN/m2, Wet, after 18 hrs, immersion in water, 170kN/m2 |

5% 5% |

1.1% 1.3% |

0.6% 0.9% |

| Flexural strength(kN/m2), min | 240 | 430 | 680 |

| Cold crushing strength, kN/m2, min |

| 720 | 1350 |

| Hot resistance under heat soaking for 24hrs Linear shrinkage (length), max at 950oC Linear shrinkage (length), max at 1050oC Loss in mass, max Compressive strength, reduction in thickness not to exceed under a load of 345 kN/m2 |

2%

15%

5% |

1.5%

11.5%

2.4% |

1.2%

9.5%

1.7% |

| Thermal conductivity(W/m K), maximum |

|

|

|

| At mean temperature 200oC | 0.080 | 0.070 | 0.070 |

| 250oC | 0.088 | 0.073 | 0.074 |

| 300oC | 0.097 | 0.079 | 0.080 |

| 350oC | 0.110 | 0.086 | 0.088 |

| 400oC | 0.121 | 0.093 | 0.095 |

| 450oC | 0.135 | 0.096 | 0.098 |

| 500oC | 0.148 |

| 0.102 |

| As dispatched, moisture content (%), max | 7.5 | 5.5 | 5.2 |

| Alkalinity, pH | 8-11 | 10 | 10 |

| Dimensional tolerance(mm) Length/width Thickness | +3 -1.5, +3 | +2 -1.5, +2 | +2 -1.5, +2 |

Company Details

Focusing on a customer-centric approach, Sharda Insulation And Refractories has a pan-India presence and caters to a huge consumer base throughout the country. Buy Insulation Material in bulk from Sharda Insulation And Refractories at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

125

Establishment

2012

Working Days

Monday To Saturday

GST NO

22AEHPP6980M1ZX

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 22AEHPP6980M1ZX

Champa, Chhattisgarh

Sales Head

Mr. Raja Rao Kamarsu

Members since

1 Years

Address

Sharda Insulation, Ghutiya, Champa, Chhattisgarh, 495671, India

calcium silicate block in Champa

Report incorrect details