Chemical Reactor - High-efficiency Stainless Steel, Advanced Chemical Reaction Engineering Design, Optimal Heat & Mass Transfer Solutions

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless steel |

| Capacity | 100-5000L |

| Dimensions | Variable |

| Pressure rating | 10-50 bar |

| Temperature range | 0-250°C |

| Agitator type | Anchored |

| Usage | Chemical, pharmaceutical, food, rubber, paint, textile, paper and pulp industries for mixing, catalysis, mass and heat transfer, environmental control, and containment. |

| Features | Chemical reactions, Efficient mixing, Versatile usage, Durable design, Precise control, High yield, Cost effective |

Product Overview

Key Features

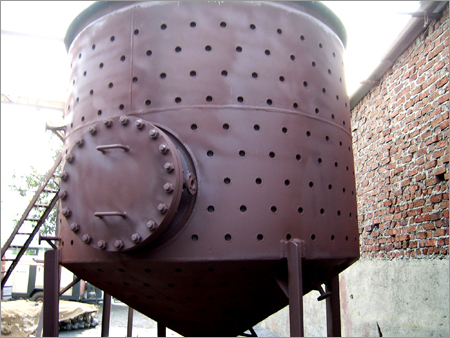

The Reactor vessel is used to achieve desired product in various industries i.e. Chemical, Pharmaceutical, Food, Rubber, Paint, Textile, Paper and Pulp etc.

The main purpose of Reactor in these industries is:

i Mixing of subtracts, contacting catalyst for rapid reaction.

i Mass transfer i.e. Gas/Liquid, Liquid/Liquid, Gas/Solid, Liquid/Solid.

i Heat Transfer.

i Control of Environment.

i Containment (protection from/of environment).

The design of a Chemical Reactor deals with multiple aspects of Chemical Engineering. Chemical Engineers design Reactors to maximize net present value for the given Reaction.

Company Details

Focusing on a customer-centric approach, Sahyadri Engineering Corporation has a pan-India presence and caters to a huge consumer base throughout the country. Buy Industrial Machinery & Parts in bulk from Sahyadri Engineering Corporation at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

20

Establishment

1982

Working Days

Monday To Sunday

GST NO

27AWVPS9253J1ZF

Payment Mode

Online Payments (NEFT/RTGS/IMPS)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AWVPS9253J1ZF

Mumbai, Maharashtra

Accepts only Domestic inquiries

Proprietor

Mr. Dinesh B Shelke

Members since

3 Years

Address

UNIT No.7, Diamond Industrial Estate, Opposite Virwani Industrial Estate, Goregaon (East), Mumbai, Maharashtra, 400063, India

chemical reactors in Mumbai

Report incorrect details