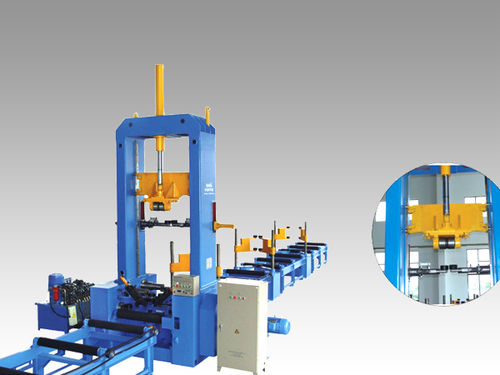

Pull Thru Welding Machine

Price Trend: 5500000.00 - 10000000.00 INR / Piece

Get Latest Price

Minimum Order Quantity :

1 Piece

In Stock

Product Specifications

| Welding Process | Submerged Arc Welding |

| Beam Configuration | Horizontal |

| Model Number | Abw Series |

| Control System | Plc Controlled |

| Hmi | Touch Screen |

| Material Handling | Automated |

| Production Capacity | 600-700 Tons/Month |

| Features | Precise Control, High Productivity, Reliable Design, Automated Process, Scalable System, Low Rework, Flexible Machine, Efficient Welding |

| Delivery Time | 1 Months |

| Sample Available | No |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Domestic Market | All India |

Product Overview

Key Features

PRIMO - Leading manufacturer of PEB Beam Welding Machines which will aid the customer enhance their productivity and Quality. We have got a wide range of products to suit Various customer needs with varied level of Automation and Beam Handling equipment.

We are a one stop solution provider for Beam Welding offering complete turnkey solutions, for Pre- Engineered building applications. Automation helps in not only deskilling, it results in low rework( especially in flange & web assembly). We have supplied and exported beam welding lines since the year 1999, and till date we have installed 150+ Beam Welding Lines overseas and in India.

PRIMO has got a strong foothold in Southeast Asia, Middle East & African market. We have catered to almost all the major Structural PEB giants in the market to meet their Project demands.

Our H Beam Welding is configured to Weld and Produce beams in H format or Horizontal format. When you buy a Beam Welding machine from Primo, you can be assured that your investment is on a most Up to date, Flexible, Scalable, Reliable & Proven machine design.

Most of our customers are using our machines for producing more than 600-700 tons per month production, which speaks volumes about our machines, their capability and reliability.

PRODUCT SPECIFICATIONS :

FEATURES

BRIEF MACHINE SPECIFICATION

Process Type

Submerged Arc Welding for fabricating Steel Beams

Horizontal Beam Welding configuration

Model Name/Number

ABW Series

ABW-2100, ABW-1850, ABW-1500, ABW-1200, ABW-1000

Usage / Application

Pre Engineered Beam Fabrication

Plate to Beam Conversion

Structural Beam Welding

Automatic SAW Beam Welding

High Rise Beam Welding Fabrication

Railway Beam Fabrication / welding

Crane Beam Welding

Trailer beam Welding

Box Beam Welding

Curved Beam Welding

Architectural Beam Welding

Tapered rafter beam welding

Machine Controls / Features

Standard Features :

Only entry Tacking is required. No full tacking needed.

Automatic aligning of beams inside Pull Thru Welder

Highly Precise Machine Controls such as Hydraulic Beam Clamping, Positioning and Pull Thru Beam transfer,

PLC Controlled Machine, Touch Screen HMI.

Advanced Single Window Parameterization / Recipe function for control of Welding Current, Beam Pull Thru Speed, Inlet & Outlet Conveyor speed & any other important parameters.

Optional features :

Laser Seam Tracking of Flange and Web beam welding

Automatic beam positioning and clamping system eliminating machine setting time.

Automatic program selection of welding parameters for various Flange and Web dimensions

Machine Modules

Standard Options :

Plate Seamer or Splice Welder

Beam Assembly and Tack Welder

Pull Thru Welder Main Welding machine

Conveyor Modules for inlet and Outlet Beam Transfer

Optional Modules Offered :

PRIMO can offer complete Material Handling systems for Beam Maneuvering such as

Beam Flipping Device

Beam Cross Transfer Device

Beam Straightening Machine

Welding Current Range

Adapted to suit various thicknesses of beams

Automation Grade

Fully Automatic / Semi Automatic

Special Application Welding

Please discuss with our Sales / Technical team about your exact requirement to offer our Best available Beam Welding Automation Solutions.

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

150

Establishment

1995

Working Days

Monday To Sunday

GST NO

33AABCP9366Q1ZP

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 33AABCP9366Q1ZP

Kanchipuram, Tamil Nadu

Deputy General Manager Sales Coordination

Mr K. Prakash

Address

Survey No. 500/5 to 500/8, Patta No. 233, Amarambedu Village, Kundrathur Post, Kanchipuram, Tamil Nadu, 600069, India

h beam assembly machine in Kanchipuram

Report incorrect details