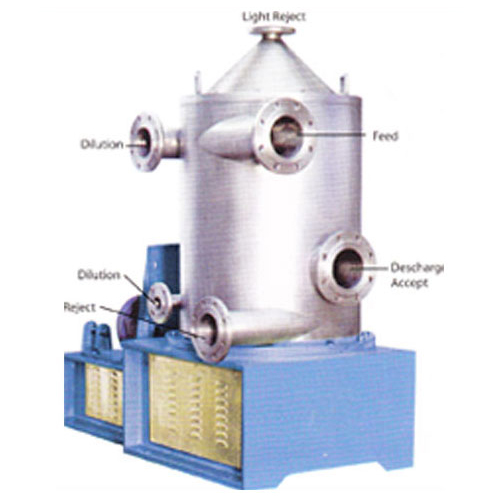

Pressure Screen - Stainless Steel, 24-hour Continuous Operation | High Strength, Rust Resistance, Easy Installation

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Dimensions | Varying |

| Operation | Continuous |

| Seals | Backup O-Rings |

| Rotor | Aerofoil Drum |

| Motor | Integral Mount |

| Basket | Wedge Wire |

| Features | High Strength, Durable Quality, Easy Install, 24-Hour Operation, Long Life, Low Pulsation, Low Friction, Easy Maintenance |

Product Overview

Key Features

Backed by extensive years of market experience and in-depth knowledge, we are able to manufacture and export a superior grade Pressure Screen. These screens are acknowledged for excellent strength & rust resistance, demanded in several industries for monitoring and analyzing pressure rate in devices or machines. Our entire range is designed by utilizing premium quality materials as per set industrial standards at well managed production unit. We offer this Pressure Screen for our clients in several dimensions at pocket friendly price.

Features:

-

High strength

-

Durable quality

-

Easy to install

Specifications:

The drive element is configured in such a way that gland housing is easily maintained without removal of the rotor and basket. The rotating assemblies are designed for continuous operation and take up belt tension/rotor radial load ensuring long life for bearing.

Stuffing box: The maintenance prone area is fitted with long life gland ropes with hardend shaft protecting sleeves and in stainless construction ensuring long life and easily approachable from the outside

Back up seals: To prevent water ingress to the top bearing oil seals are provided on hardened and ground sleeves. At all points back up O rings are provided for safety against water entering into the rotating elements through threaded holes etc.

Drum rotor: Our rotor is a special aerofoil drum rotor with continuous sweeping action with low pulsation. This improves screen life. The rotor has less friction due to load acting only on one surface of the rotor. Unlike other designs in which drag load acts on both sides of aerofoil. Power consumed by our screens is less by about 30% compared to competitors.

Lightweights: The screen is provided with light weight extraction point on the top of the screen door.

Dilution line: A dilution line is available at the bottom of the screen to counteract the problems faced by the thickening of pulp during its downward motion. This eliminates matting problem.

Motor mounting: Our screen comes with an integral base on which the motor can be mounted, avoiding additional foundations. Motor bracket is mounted on machined surface and aligned at our works and alignment will not be lost during belt change. (This facility is not provided by competitors.)

TECHNICAL DETAILS OF PRESSURE SCREENS

We have been manufacturing screens from 1994.Our first two screens were supplied to M/s.ASVPM with imported baskets of 0.25mm slot size from Finch West Germany, way back in 1994.

Pressure screen supplied

14 years back by UMAC Functions well customer ASVPM ,TN

We have supplied more than 50 pressure screens with drilled and slotted baskets.

Our design is a combination of BLACK CLAWSON and Voith. The baskets are imported from either AFT/Andao. The baskets are of wedge wire with high open

Maintenance

Lubrication points are bought outside the screen for ease of relubrication.

You can just unscrew few bolts and lift the shaft with bearings for bearing-change. Piping and body need not be touched at any time.

SIZES AND MODELS:

MODEL PS

40,PS,50,PS,60,PS,80,PS,100

Nominal throughput

BD tons/24hrs,40 70 110 160 170

Stock consistency % 0.8-

1.2%,0.8-,1.2%,0.8-,1.2%,0.8-,1.2%,0.8-,1.2%

Slot width mm 0.3- 0.3- 0.3 0.3- 0.3-

Motor speed rpm 1500 1500 1500 1500 1500

Nominal Motor

Rating Kw

15 22 30 37 55

Hydraulic capacity lpm 2500 7,000 9,000 12,000 27,000

INLET & OUTLET PIPE

SIZES

Nom.Bore

150 dia 250 dia 250 dia 400 dia 400

Company Details

Focusing on a customer-centric approach, UNIQUE MACHINE AND SYSTEMS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Paper, Paper Converting Machinery in bulk from UNIQUE MACHINE AND SYSTEMS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

10

Establishment

1990

Working Days

Monday To Sunday

GST NO

33AAHPU1720E1Z2

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 33AAHPU1720E1Z2

Coimbatore, Tamil Nadu

Ceo

Mr. K. Unni Krishnan

Address

566, First Cross Kuppanaickenpalayam, Thadagam Road, Coimbatore, Tamil Nadu, 641108, India

pressure screen in Coimbatore

Report incorrect details