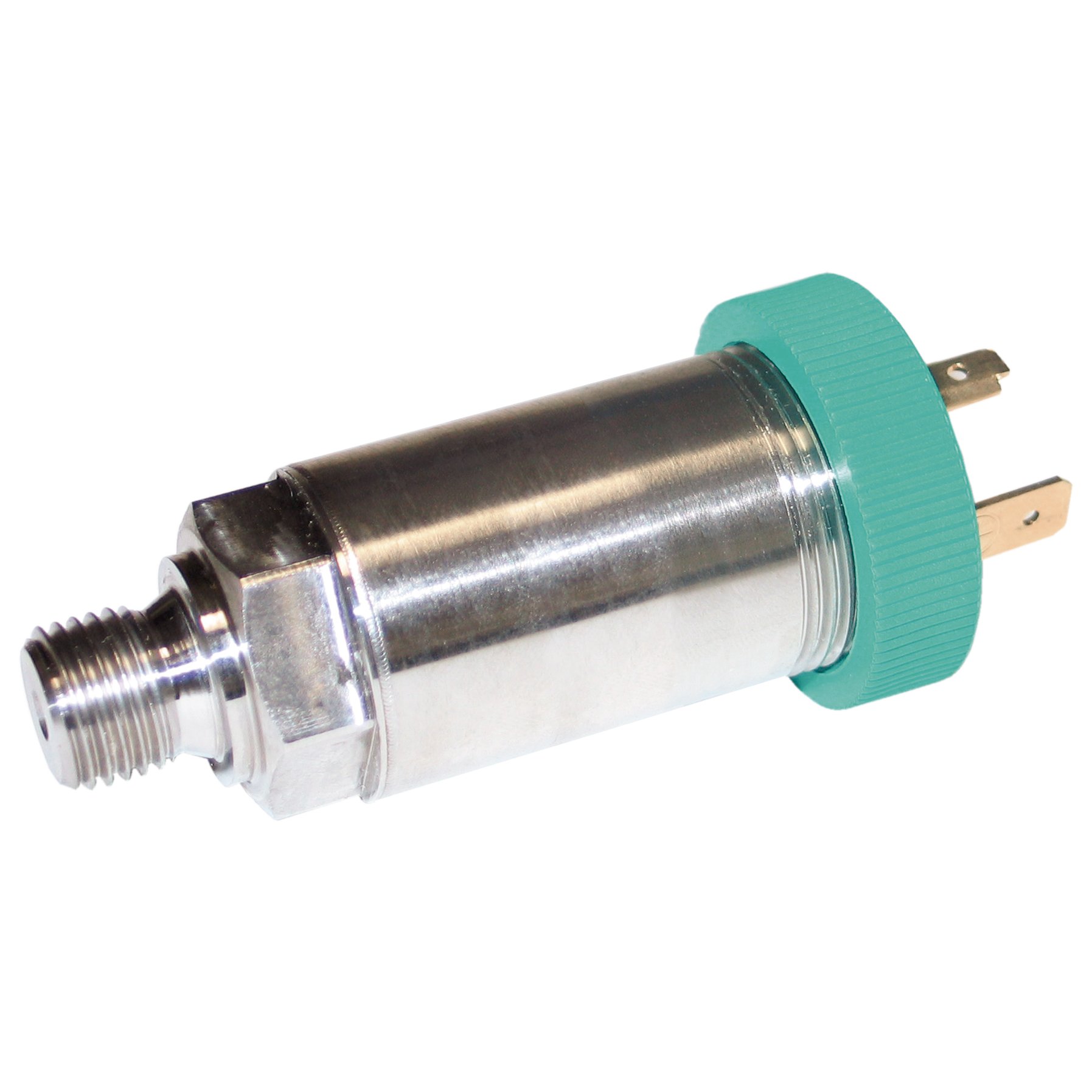

High Precision Torque Sensor - 8661

Price Trend: 2750.00 - 4800.00 EUR / Piece

Get Latest Price

Minimum Order Quantity :

1 Piece

In Stock

Product Specifications

| Material | Aluminum, Steel |

| Dimensions | Variable |

| Accuracy | 0.1% |

| Output | 0-10V, USB |

| Speed | 25000 rpm |

| Resolution | 0.045deg |

| Encoder | Optional |

| Features | High accuracy, Low linearity error, Non-contact operation, Zero-maintenance, Digital interface, Easy integration, Versatile applications |

| FOB Port | Hamburg |

| Delivery Time | 1 Week |

| Sample Available | No |

| Packaging Details | Weight: 1Kilograms |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

Product Overview

Key Features

The 8661 precision torque sensor is the ideal choice for reliable measurement of static and dynamic clockwise and counter-clockwise torques. Thanks to its high measurement quality and low linearity error, the sensor is equally at home in quality control or research & development. Designed for non-contact operation and zero-maintenance, the 8661 is also ideally suited to the production environment, whether on shift-based production lines, test benches or end-of-line test systems. The 8661 torque sensor is the specialist device for constant torque measurements during continuous operation and for test-bench measurements of holding, friction, break-away or tightening torques.

Company Details

With passion for precision and quality the German brand burster precision measurement technology develops and manufactures since 60 years as one of the most important suppliers precision instruments, sensors and systems for sensor signal processing and process monitoring. burster applies highest quality standards in its production of components and systems in accordance with EN ISO 9001:2015. burster supplies 7500 customers worldwide. bursters innovative and experienced team provides intensive application support even before a decision to buy is made. Solving complex measurement problems and integrating measurement and test technology into production environments for production control, quality assurance and test-equipment monitoring are everydays instrumentation tasks. burster supplies measuring technology ranging from individual sensors to system solutions, with emphasis on plant construction and engineering, automation, the automotive industry and its suppliers, electrical and electronic engineering and chemicals industry. It also has a presence in numerous other sectors and future markets such as electro-mobility, alternative energies, medical engineering and biotechnology. In addition to solutions employing standard products, burster provides custom OEM solutions. Many years of experience as manufacturer of measuring sensors and instruments guarantee optimum solutions. This has earned burster an international reputation for innovation geared to customers needs.

Business Type

Manufacturer

Employee Count

150

Establishment

1961

Working Days

Monday To Friday

Payment Mode

Letter of Credit (L/C), Telegraphic Transfer (T/T)

Certification

DAkkS-Akkreditierung, ISO 17025, ISO 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Gernsbach, Baden-Wurttemberg

Marketing Manager

Mr Matthias Bodemer

Members since

7 Years

Address

Talstrasse 1-5, Gernsbach, Baden-Wurttemberg, 76593, Germany

torque sensors in Gernsbach

Report incorrect details