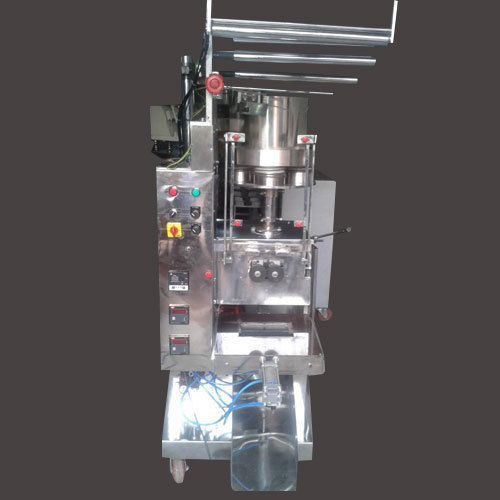

Plodder Machine - Premium Quality Alloy Components , Superior Strength And Rust Proof Design For Continuous Soap And Detergent Production

Price: 600000 INR / Unit

Get Latest Price

Minimum Order Quantity :

1 Unit

In Stock

Product Specifications

| Material | Stainless Steel |

| Dimensions | Variable |

| Power | Variable |

| Capacity | Variable |

| Weight | Variable |

| Motor | Electric |

| Warranty | 1 Year |

| Features | Durable Design, High Output, Easy Operation, Precise Dimensions, Continuous Production, Affordable Price, Rustproof, Fine Strength |

| Type | Other |

| Automatic Grade | Automatic |

| Color | Metallic |

| Payment Terms | Cash Advance (CA), Cash in Advance (CID) |

| Supply Ability | 2 Per Month |

| Delivery Time | 60 Days |

| Main Domestic Market | All India |

Product Overview

Key Features

Toilet Soap Plodder Machine (Soap Extruder)

A toilet soap plodder machine, also known as a soap extruder, is a piece of equipment used in the final stages of soap production to extrude a continuous bar of soap. It transforms the raw soap mixture into solid bars by squeezing and extruding it through a die. The plodder compresses, homogenizes, and air-free extrudes the soap, resulting in a high-quality, finished soap bar.

Industrial Applications:

Small scale toilet soap making machine, bar soap, home laundry soap, mini toilet soap plodder.

How It Works:

Compression and Mixing: Uses twin worm screws moving in opposite directions to generate high squeezing force, ensuring thorough mixing and compression.

Refining: Soap mixture is passed through a refining plate or screen to remove impurities and ensure a consistent texture.

Extrusion: Compressed and refined soap is forced through a die or nozzle to shape it into a continuous bar.

Vacuum Chamber: Removes air bubbles from the soap mass, producing a denser and uniform bar.

Cutting and Stamping: Continuous bar is cut into individual pieces and stamped with desired shape or logo.

Types of Plodders:

Duplex Vacuum Plodders: Two stages a a refiner and an extruder, connected by a vacuum chamber.

Simplex Plodders: Single screw or worm for extrusion.

Key Features:

High compression for dense and uniform soap bars

Vacuum system for air bubble removal

Refining capabilities for smooth texture

Customizable die shapes for various sizes

Durable stainless steel construction for corrosion resistance

Technical Details (Sample Model):

Power: 5 HP

Function: Uses two worm screws moving clockwise and anticlockwise at similar RPMs

Sources:

Jagdish Group: Soap Duplex Plodder Machine | Toilet Soap Making Plant

Atom Machinery: Demystifying Toilet Soap Plodder Machines

Company Details

Business Type

Exporter, Importer, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler

Employee Count

35

Establishment

2006

Working Days

Monday To Saturday

GST NO

24ABFPL9700J1ZN

Payment Mode

Cheque

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24ABFPL9700J1ZN

Ahmedabad, Gujarat

Manager

Mr Rameshbhai

Members since

2 Years

Address

31, Shayona Industrial Estate, Nr. Panchratna Estate, Ramol Chokdi, Vatva, Ahmedabad, Gujarat, 382445, India

toilet soap making machine in Ahmedabad

Report incorrect details