Plastic Injection Moulding - High-quality Plastic Components Manufacturing, Custom Molds And Precision Auxiliary Equipment

Price:

Get Latest Price

In Stock

Product Specifications

| Machine Capacity | 100-1300 tons |

| Material Types | Various plastics |

| Mold Material | Tool steel |

| Accuracy | ±0.01mm |

| Production Rate | Variable |

| Usage | Air conditioner components, consumer durables |

| Compliance | ISO 9001 |

| Features | High precision, Customizable parts, Short lead times, ISO 9001, Premium quality, Fast turnaround |

Product Overview

Key Features

Plastic Injection Moulding

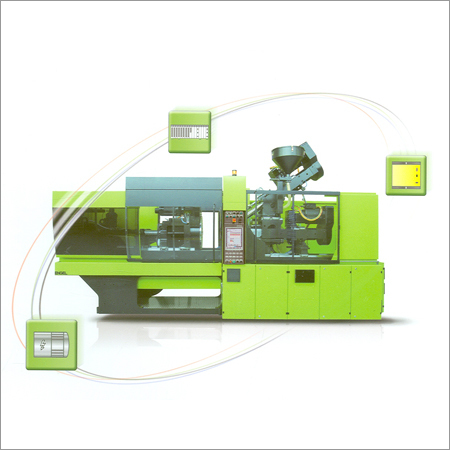

We have installed 8 high-end injection molding machines at Dehradun ranging from 100 tons to 1300 tons. These machines are of top quality Japanese makes like Toshiba, Mitsubishi, and Ube Max while our Negri Bossi machine is from Italy.

We have all the essential auxiliary equipment required for precision molding in place. We manufacture plastic components, assemblies and sub-assemblies for sale to clients and also equipment for captive consumption like temperature controllers, chillers, hot runner temperature controllers etc.

At Amber we manufacture premium quality plastic molded components which are used in air conditioners and other consumer durables. The components are customized as per requirement and specifications provided by different companies and are always in conformity with international standards.

With our in-house mold manufacturing and maintenance capability, Amber can develop parts in extremely short time frames. Our experienced and well qualified team, world class machinery and well designed physical infrastructure coupled with ISO 9001:2008 certified manufacturing processes give us the ability to deliver high quality injection molded parts to our customers as per schedule and as per specification day after day.

Injection Molding

Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts. A wide variety of products are manufactured using injection molding, which vary greatly in their size, complexity, and application. The injection molding process requires the use of an injection molding machine, raw plastic material, and a mold. The plastic is melted in the injection molding machine and then injected into the mold, where it cools and solidifies into the final part.

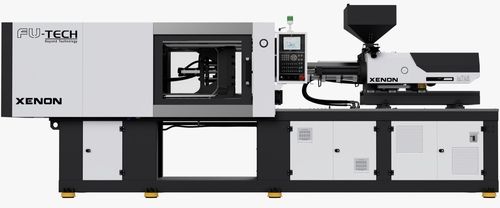

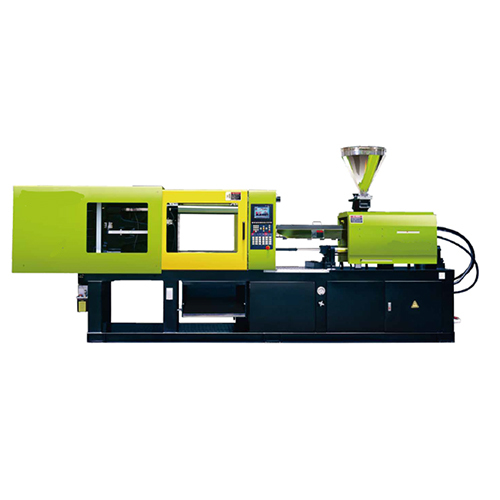

Injection Molding Machine

Injection molding machine is divided into 2 units i.e. a clamping unit and an injection unit. The functions of the clamping unit are opening and closing a die, and the ejection of products. There are 2 types of clamping methods, namely the toggle type shown in the figure below and the straight-hydraulic type in which a mold is directly opened and closed with a hydraulic cylinder.

The functions of the injection unit are to melt plastic by heat and then to inject molten plastic into a mold. The screw is rotated to melt plastic introduced from the hopper and to accumulate molten plastic in front of the screw ( to be called metering ) . After the required amount of molten plastic is accumulated, injection process is stared. While molten plastic is flowing in a mold, the machine controls the moving speed of the screw, or injection speed. On the other hand, it controls dwell pressure after molten plastic fills out cavities. The position of change from speed control to pressure control is set at the point where either screw position or injection pressure reaches a certain fixed value.

Mold

A mold is a hollow metal block into which molten plastic is injected to from a certain fixed shape. Although they are not illustrated in the figure shown below, actually there are many holes drilled in the block for temperature control by means of hot water, oil or heaters.

Molten plastic flows into a mold through a sprue and fills cavities by way of runners and gates. Then, the mold is opened after cooling process and the ejector rod of the injection molding machine pushes the ejector plate of the mold to further eject moldings.

Company Details

Focusing on a customer-centric approach, AMBER ENTERPRISES INDIA PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Injection Moulding in bulk from AMBER ENTERPRISES INDIA PVT. LTD. at Trade India quality-assured products.

Business Type

Exporter, Supplier

Establishment

1994

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Mon, Nagaland

Marketing Manager

Mr. Mukesh Chopra

Address

No. C-38, Engin Part-2, gagan vila, Mon, Nagaland, 798602, India

injection moulds in Mon

Report incorrect details