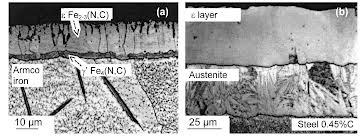

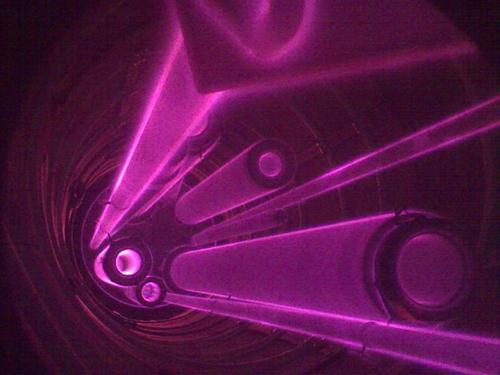

Owing to our access to advanced resources and technology we are able to provide world-class Plasma Nitriding Services. These are services are ensure optimum wear resistance of different types of metallic components. We have established advanced facilities that help us to provide our services in accordance with the clients' expectations. Our Plasma Nitriding Services are demanded in the market and acclaimed by clients owing to their high reliability flexibility and time-execution.Other details:Plasma heat treatment especially PulsPlasma nitriding and pulse plasma nitrocarburizing is used for surface treatment of work pieces for protection against wear. For the treatment by plasma the parts have to be placed in a vacuum chamber and are electrically insulated from the case. At a pressure of 100 - 1000 Pa a pulsed electrical D.C. voltage of several hundred volts is used between work piece and chamber whereby the workload is switched cathodically. The ionizing of the remaining gas in the chamber results in a glow discharge. The electrical positive ions are moving towards the work piece and impact with high kinetic energy. Specification: 4TON(1200 W X 1200 H X 1800 D)mm Hot Wall Bell Type Furnace Vacuum Chamber with Plasma View Port 3-Zone Heating 75KW 2 main X 3 workload Thermocouple for Regulation Supervision & Recording 5 Gas Control Unit Gas Mixture & Gas Regulation including mass flow controllers(MFC). Internal Fan for Regulation Special Features: Pulsed Technique by PLATEG Auxiliary Heating & Thermal insulation Gas Control Unit Process Control & Regulation Applications: Plasma Nitriding Plasma Nitrocarburizing Pre & Post Oxidation (PulsPlasma) Oxynitrocarburising LPlasma Assisted Carbonitriding