Vacuum Carburizing Services By Metals India

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Capitalizing on advanced resources, our firm has been able to provide highly effective Vacuum Carburizing Services. These services are known for their variegated benefits such as case depth uniformity, wear resistant part surfaces, bright & clean parts and minimal distortion. We ensure timely execution of these services incorporating latest machines and tools. Furthermore, clients expectations are paid optimum attention while providing our highly cost-effective and reliable Vacuum Carburizing Services.

Other details:

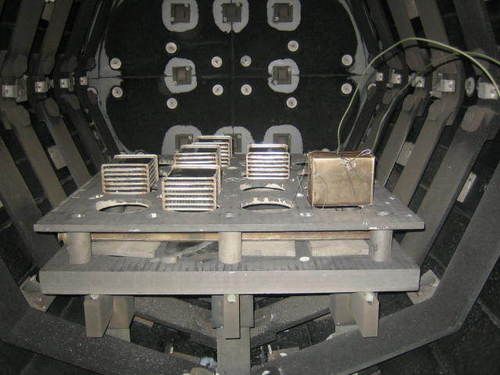

Low torr(pressure) range vacuum carburizing for optimum case hardening. The benefits are wear resistant part surfaces, case depth uniformity, minimal distortion and bright, clean parts.

Low pressure Carburizing reduces part distortion & precise control of temperature & acetylene gas mixtures for optimal case depth.

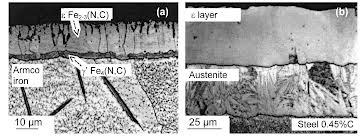

Metallurgically Low torr range vacuum carburizing prevents microstructure surface intergranular Oxidation(IGO) and decarburization. The avoidance of IGO provides high integrity to the case. The presence or absence of carbides can be controlled according to the specification requirements. Additionally the process produces compressive residual stress for improved fatigue life. Metallurgical properties attained provide optimal surface & core hardness extending part performance & wear life.

ADVANTAGES:

- Efficient part handling improves quality & turnaround

- Capacity to process mixed parts with various packed densities & materials

- High carburizing temperature possible up to 1980OF (1080OC) resulting in faster diffusion stages

- Environmentally friendly process

- Eliminates soot and tar

- P class="prhdl"Free of surface oxidation

- Uniform case depth including improved gear root to pitch ratios

- Elimination of intergranalar/internal oxidation, which may occur during gas carburizing

- Minimal distortion with precision controls

- Ability to carburize blind holes

- Excellent carbon penetration in to dense loads

- Bright metallic & dry parts, no washing required

- No surface Decarburization

Company Details

Focusing on a customer-centric approach, METALS INDIA has a pan-India presence and caters to a huge consumer base throughout the country. Get Others from METALS INDIA at Trade India quality-assured services.

Business Type

Service Provider

Employee Count

8

Establishment

1994

Working Days

Monday To Sunday

GST NO

06AAAFM0122B1ZB

Certification

ISO 9001 : 2000

More Product From This seller

Seller Details

GST - 06AAAFM0122B1ZB

Ballabgarh, Haryana

Accepts only Domestic inquiries

Director

Mr Ankit Gupta

Address

Plot No. 128, 130 & 139, Sector-25, Ballabgarh, Haryana, 121004, India

Report incorrect details