Petroleum Denitrification(denox) Additive

Price:

Get Latest Price

In Stock

Product Specifications

| Color | Off-white |

| Form | Powder |

| Packaging | 25kg drums |

| Particle size | Microsperoidal |

| Dosage | 1-2.5 wt% |

| Application | FCCU regenerator |

| Composition | Catalytic additive |

| Features | NOx reduction, Emission control, Regulatory compliance, Cost effective, Improved efficiency, Easy to use, Wide application |

Product Overview

Key Features

RDNAAR is a NOx reduction additive, designed to catalytically reduce NOx emissions from an FCCU regenerator flue gas stack.

RDNAAR has been utilized to:

a c Meet local/federal NOx regulations

a c Balance refinery wide NOx emissions

a c Provide economic flexibility to process feeds high in nitrogen

a c Avoid issues associated with SCR installations

Commercial experience

Since its introduction in 1997, RDNAAR has been successfully evaluated in a wide range of FCCUs. In commercial application, RDNAAR provides an average 40 a 50% NOx reduction, when dosed at rates of 1.0wt% to 2.5 wt% of fresh catalyst additions.

RDNAAR can be used effectively with conventional platinum based CO combustion promoters. However, for the best NOx reduction performance, Shanghai Rich company recommends using RDNAAR in combination with our CO combustion promoter, RCAAR has also been utilized with other additives, such as Super RDSAAR, without any debit to performance of either additive.

Why it works

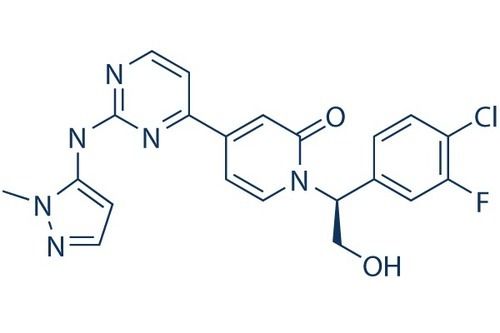

The chemistry of NOx formation within the FCCU regenerator is extremely complicated and typically unit specific. Early experiments by Shanghai Rich company showed that the source of NOx is the nitrogen bound to heavy molecules in the FCCU feed, which are ultimately burned as coke in the regenerator. About 50% of the nitrogen in FCCU feed typically enters the regenerator; however, less than 10% of this nitrogen is usually emitted as NOx. Coke bound nitrogen can take one of three paths: it can be reduced to N2, oxidized to NO and NO2, or it can remain in an intermediate stage, such as NH3 or HCN. These intermediate stage nitrogen species have the potential to oxidize to N2 or NOx, and there are multiple unit factors which can play a role in the direction they take. For example, high dosing rate of a CO promoter can cause these species to be oxidized to NO, increasing overall emissions. Use of CO promoters will also reduce the amounts of various reductants present in the regenerator; thereby further exacerbating NOx emissions in the flue gas. The simplified mechanism of NOx formation is shown below .

The discovery of this NOx formation mechanism led to the development of catalytic NOx control technologies. Shanghai Rich company offers RDNAAR as a NOx reduction additive.

Product options

RDNAAR additive is a microspheroidal powder, having physical characteristics similar to those of fluid cracking catalyst and is available in the following packaging options:

a c 25 kg drums of bulk product

a c Pre-blended with cracking catalyst

Company Details

Based in international business center Shanghai/China, Richemi established in 2005, registered capital of 20 million CNY. As one of biggest manufacturers in China, under fully effort on business development in last decades, invest factories producing chemicals as well as build strategy partnership of domestic site and company in terms of research, manufacture, marketing and sales along with import/export chemicals, such as: Petroleum addtitive; phthalic anhydride, DOP plasticizer; Indole, pyridine etc..

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

50

Establishment

2005

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Shanghai, Shanghai

Sales Director

Mr Siegen Wang

Address

No. 285, West Jianguo Road, Shanghai, Shanghai, 200031, China

petroleum additives in Shanghai

Report incorrect details