Stainless Steel Ointment Manufacturing Plant With Capacities Ranging From 100 Kg To 1000 Kg

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Drive Type | Electric |

| Color | Other, Silver |

Product Overview

Key Features

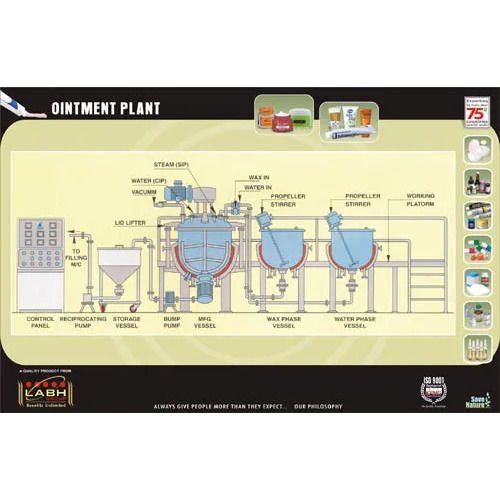

Water Phase Vessel:

The Water Phase Vessel is a jacketed cylindrical tank with torrispherical dish ends. A propeller type stirrer is provided for agitating the liquid.

Wax Phase Vessel:

The Wax Phase Vessel is a jacketed cylindrical tank with torrispherical dish ends. A propeller type stirrer is provided for agitating the wax or oil. A conical filter filters out impurities before the wax is transferred to the manufacturing vessel.

Manufacturing Vessel:

The Manufacturing Vessel is a jacketed cylindrical vessel with a conical bottom and anchor type agitator. It is used to mix the viscous product from the Water and wax phase vessels.

Homogenizer:

The Homogenizer Tank or Online is used with the manufacturing vessel to reduce particle size and promote uniform mixing.

Storage Vessel:

The Storage Vessel is a tank with a conical bottom in which the product is collected and stored until it has to be transferred to the filling line. It can be provided with an anchor type stirrer and a jacket as per requirement.

Transfer Pump:

The Transfer Pump (twin lobe) is used to transfer the product from the manufacturing vessel to the storage vessel.

Metering Pump:

The Metering Pump is a positive displacement pump through which the product can be transferred to the filling line at a controlled flow rate.

Inter-Connecting Pipeline:

The Inter-Connecting Pipeline is provided for the plant as per the layout. All pipes are electro-polished from the inside.

Working Platform:

A suitable Working Platform is provided to help in the maintenance and operation of the plant.

Control Panel:

The electrical control panel houses the necessary electrical components and controls needed to operate the plant. Custom built automation can be incorporated to improve efficiency and reduce errors.

Company Details

Prominent Manufacturer of Mixing Equipment's, Our Equipment's Range is Mixing Tank, Agitator, Jacketed Tank, Storage Vessel, Ointment Manufacturing Plant, Sugar Syrup Manufacturing Plant, High Shear Mixer, High Shear Batch Mixer, Bottom Entry High Shear Mixer, Bottom Entry Agitator, Side Entry Agitator, Cartridge filter with SS housing, High Shear Mixer with Up Down Mechanical Stand, Motorized Up Down Stand and all the Fabrication Items.

Business Type

Manufacturer, Supplier

Employee Count

10

Establishment

2019

Working Days

Monday To Saturday

GST NO

24DCOPP9801D1ZG

Payment Mode

Cash on Delivery (COD)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24DCOPP9801D1ZG

Ahmedabad, Gujarat

Proprietor

Mr. Sagar Panchal

Address

132, Adarsh Silver Indl Est,B/H Kotak Mahindra Bank,Road No.5, Kathwada GIDC, Ahmedabad, Gujarat, 382350, India

ointment manufacturing plant in Ahmedabad

Report incorrect details