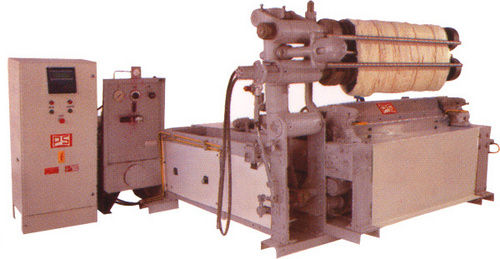

Nylon Crimped Yarn Machine

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Heater | Vapour phase |

| Temperature | 160-240*C |

| Cooling Track | Nitrogen Ultra Finished |

| Twist unit dia | 54.5mm |

| Discs | PU/Ceramic |

| Package Dia | 435mm |

| Stroke | 250mm |

| Features | High speed, Stable process, Power efficient, High stability, Precise package, Low maintenance, Simple yarn path, Temperature control |

| Payment Terms | Cheque |

| Supply Ability | 50-60 Machines Per Month Per Month |

| Delivery Time | 5-8 Weeks Week |

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Western Europe, Africa, Central America, Eastern Europe, Middle East, South America, Asia, North America, Australia |

| Main Domestic Market | All India |

Product Overview

Key Features

- Twist stopper giving stable process at high speed

- New high curvature 2.0 MTR. Vapour phase power efficient open heater, Temperature range 160*C to 240*C.

- Hight curvature Nitrogenesefd Ultra Finished Cooling Track

- High stability friction twist unit 54.5mm Dia. 9mm PU Discs/ Ceramic Discs

- Yarn Cutter

- 1 / 2 FR Nip roller

- Optional tension monitor fully featured system

- Four high rotary creel simple yarn path to input feed with minimum drag

- Maximum package 435mm Dia

- Yarn take up using heavy duty low maintenance cradles. Revised traverse box for high speed. Package 250mm stroke max. Dia. 250mm max. Taper Angle option 3,9 and 18 Degree, Revised multiple axial disturbance program for precise package build.

Company Details

Welcome to Himson Himson Engineering Pvt.Ltd. is the flagship company of the Himson Bhogibhai Group. It is one of the largest manufacturer of textile machinery in India with the experience of more than 3 decades. The engneering activities of the group are carried out under different divisions as independent profit centers. Each center is self sufficient and has its own management systems which works under the direct control of Head-Quarters located at Surat, Gujarat, India. Initially , in the year 1978, HIMSON tied up with Earnest Scragg Sons Ltd., UK to manufacture Draw Texturising Machines in India. Since then, the strategy has been to acquire the best available technology from the reputed and innovative internationally leading companies and upgrade the same with help of the experts around the world in conjuction with our in-house development experts and considerably long machine-building experience. This strategy has worked very well and eventully, made the company successful in its field in India & Abroad. Today, the company enjoys significant market share of Synthetic Yarn Processing Machinery in India. (Supplied more than 3000 Draw Texturising machines - DTY) the fast growth has been sustained on continuous upgradation & design and manufacturing facilities by installing most modern CNC machining centers, fabrication units and metal finishing shop in-house together with the latest Design and Development Center equipped with modern CAD/CAM facilities and latest state-of-the art designing softwareâÂA ÂA s to achieve highest accuracy and maintaining stringent quality standards, benchmarked against the best in the world. Himson Engineering Pvt Ltd is accredited with ISO 9001:2000 Certification. Today, HIMSON enjoys high reputation for in-house research and technology developments and an efficient and reliable After-Sales-Services. In year 1998, HIMSON entered into a technical collaboration with M/s. Teijin Seiki Textile Machinery Co. Ltd., Japan to manufacture High Speed Draw Texturising Machines (DTY) with Energy Conserving Short Heaters and Auto Doffing. Himson Engineering enjoys a very respectful image as supplier of world class textile machines and is the leader in almost all the products that it manufactures. Many of the products are exported to developed as well as developing countries. The manufacturing facilities are now also offered to the Indian & International industries, to fully exploit the capacities which has been generates over the years. In the year 2008, Himson Engineering Pvt Ltd also received a prestigious order from Alok Industries Ltd, one of the leading textile unit in India for supply of Auto âÂA ÂA Doffing Draw Texturising Machine (DTY). Himson Engineering Pvt Ltd has executed this prestigious order for supply of Himson TMT Draw Texturising Machine Model ATH âÂA ÂA 12 F/V each with 288 spindles in joint corporation with world re-known TMT Japan (TMT Machinery , Inc Japan) This is the 1st time in India Auto Doffing Machines are manufactured and installed , also its 1st time in world to supply this machine with 288 spindles.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

300

Establishment

2006

Working Days

Monday To Saturday

GST NO

24AABCH7916A1Z1

Payment Mode

Cash on Delivery (COD), Cash in Advance (CID)

Certification

ISO 9001:2000

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AABCH7916A1Z1

Surat, Gujarat

Marketing Manager

Mr. Girish Purohit

Address

Hiralal Colony, Ashwani Kumar Road Surat, Gujarat, 395008, India

yarn machine in Surat

Report incorrect details