Nitrogen Plant

Price:

Get Latest Price

In Stock

Product Specifications

| Purity | 99.9995% |

| Technology | PSA |

| Production | On-site |

| Material | Steel |

| Dimensions | Variable |

| Power | Variable |

| Usage | Industrial nitrogen generation for various sectors including metallurgical, chemical, pharmaceutical, and petroleum industries. |

| Compliance | ISO |

| Features | High purity, Low costs, PSA tech, On-site gen, Reliable supply |

Product Overview

Key Features

Since commencement, we are prominent manufacturer and supplier of Nitrogen Plant that is designed for numerous applications, wither its small or large. This plant allows the user to generate their own nitrogen by making use of atmospheric air as raw material with well approved PSA technology. Our Nitrogen Plant is demanded and required in various industries including Metallurgical, Chemical, Synthetic & Fiber, Pharmaceutical, Petroleum, Optical Fiber, Aircraft & motor vehicle tires, Electronic and Hypoxic air fire prevention system

Other Detail:

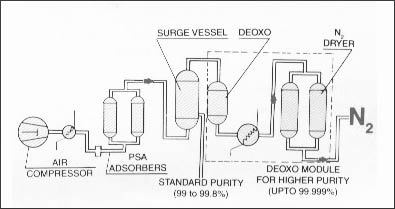

The technology of air-to-nitrogen production with the use of adsorption processes in nitrogen generators is well studied and widely applied at industrial facilities for the recovery of high-purity nitrogen.

The operating principle of a nitrogen generator utilizing the adsorption technology is based on the dependence of the adsorption rates featured by various gas mixture components upon pressure and temperature factors. Among nitrogen adsorption plants of various types, pressure swing adsorption (PSA) plants have found the broadest application world-wide. The system's design is based on the regulation of gas adsorption and adsorbent regeneration by means of changing pressures in two adsorber-adsorbent-containing vessels. This process requires constant temperature, close to ambient. With this process, nitrogen is produced by the plant at the above-atmospheric pressure, while the adsorbent regeneration is accomplished at below-atmospheric pressure.

The swing adsorption process in each of the two adsorbers consists of two stages running for a few minutes. At the adsorption stage Oxygen, H2O and CO2 molecules diffuse into the pore structure of the adsorbent whilst the nitrogen molecules are allowed to travel through the adsorber-adsorbent-containing vessel. At the regeneration stage the adsorbed components are released from the adsorbent vented into the atmosphere. The process is then multiply repeated.

Advantages:

High nitrogen purity

PSA nitrogen generator plants allow production of high-purity nitrogen from air, which membrane systems are unable to provide - up to 99.9995% nitrogen. This nitrogen purity may also be ensured by cryogenic systems, but they are considerably more complex and justified only by large consumption volumes. The nitrogen generators use CMS (carbon molecular sieve) technology to produce a continuous supply of ultra high purity nitrogen and are available with internal compressors or without.

Low operating costs

- By substitution of out-of-date air separation plants nitrogen production savings largely exceed 50%.

- The net cost of nitrogen produced by nitrogen generators is significantly less than the cost of bottled or liquefied nitrogen.

Company Details

Focusing on a customer-centric approach, SAI SATYA ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Get Oxygen & Nitrogen Gas Plants from SAI SATYA ENGINEERS at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

10

Establishment

2011

Working Days

Monday To Sunday

GST NO

07AUBPD0281F1Z7

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AUBPD0281F1Z7

New Delhi, Delhi

Manager

Mr. Nivit Dahiya

Address

G-2, Rama Park Road, Mohan Garden From Pillar No. 764, Uttam Nagar, New Delhi, Delhi, 110059, India

Report incorrect details