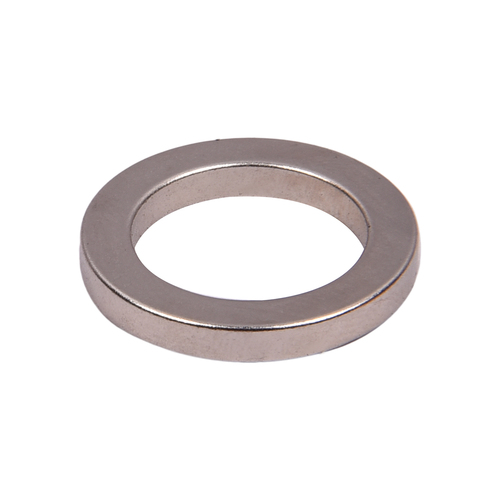

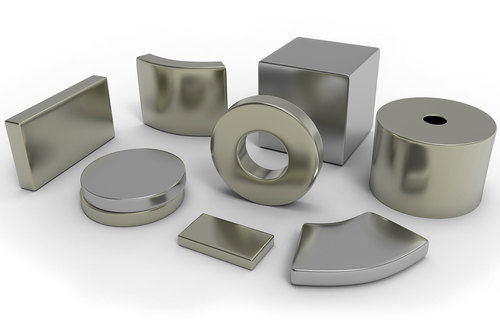

Neodymium Magnets - Neodymium Iron Boron Alloy, Silver Color, Multi-purpose Permanent Magnet Solution

Price Trend: 10.00 - 10000.00 INR

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Application | Multi Purpose |

| Product Type | Magnets |

| Magnet Category | Permanent Magnets |

| Magnet Type | Neodymium Iron Boron Magnet |

| Color | Silver |

| Payment Terms | Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Western Union, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Delivery Point (DP), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA) |

| Supply Ability | On Order Per Day |

| Delivery Time | 2 Week |

| Main Export Market(s) | Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia |

| Main Domestic Market | All India |

Product Overview

Key Features

A Neodymium magnet, also known as NdFeB or Neo magnet, is the strongest known type of permanent magnet. Because of their lightweight, strength and the consistency of their magnetization, Neodymium Magnets have become a popular choice for a wide variety of applications, from loudspeakers to magnetic therapy jewelry. A rare earth magnet is made from an alloy of neodymium, iron, and boron.

Machining & Magnetization

Adams designs and manufactures its own magnetizing fixtures either for use in house by customers as required.

Unlike other types of magnets, Neodymium magnets have a high resistance to demagnetization. They cannot be formed with conventional drilling, turning or milling processes, and must be ground before they are magnetized. Additionally, large or complex assemblies are usually magnetized prior to assembly. Standard tolerances for Neo magnetsare +/-.005 for ground dimensions. They require extremely high magnetizing fields and particular consideration must be given to this when designing complex assemblies. A Neodymium magnetcan be magnetized in any direction as long as it is aligned properly. In some instances multiple pole magnetization is not possible; when it is possible, special fixtures are required.

Temperature Considerations with Neodymium Magnets

A low coercivity grade Neodymium magnet may begin to lose strength if heated above 176A A F (80A A C). High coercivity grade Neodymium Magnets have been developed to function at temperatures up to 428A A F (220A A C) with little irreversible loss. The need for low temperature coefficient in neodymium magnet applications has triggered several grades to be developed to meet specific operating requirements. Please refer to our chart of magnetic properties to compare the characteristics of each grade.

Demagnetization Curves

A second quadrant demagnetization curve provides information about the magnetic characteristics of a magnet, including the magnetic field strength and how resistant it is to demagnetize. How it is used in a magnetic circuit will affect its performance. When a permanent magnet is fully magnetized, its magnetic domains are aligned. Certain conditions such as temperature and reverse magnetic fields can cause some of the domains to lose this alignment and reverse, triggering the magnet to lose some or all of its magnetic field.

Corrosion Protection

While today's Neo magnets are more temperature and corrosion-resistant, a protective coating is still necessary for certain applications.

Gluing Magnets

Several factors must be considered to assure the effective performance of the magnet, the adhesive and the resulting bond. These include the chemical and physical properties of the magnets and the surfaces to which they are affixed. Detailed coverage of all these factors, along with some adhesives to try, is covered in our white paper Gluing Magnets.

Neodymium Magnet Applications

Neodymium magnets have replaced Alnico and ferrite magnets in many applications where strong permanent magnets are required, because their greater strength allows the use of smaller, lighter magnets.

Company Details

MAXIMA RESOURCE was founded in the year 1996 by professional entrepreneurs, Since then it has emerged as an industry pioneer and leader in the field of Magnets & Magnetic solutions, Vacuum Pumps and Systems , apart from helical Springs and Disc Springs

Business Type

Manufacturer, Supplier

Employee Count

25

Establishment

1996

Working Days

Monday To Sunday

GST NO

29AITPC5245J1ZT

Payment Mode

Cash Advance (CA)

Certification

ISO 9001 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 29AITPC5245J1ZT

Bengaluru, Karnataka

Director

Mr Chandra Hasa G K

Address

N0 18/1, Survey No 8371/ 824 3rd A Cross , Vrushabhavathi Nagar, Kamaksipalya, Bengaluru, Karnataka, 560079, India

ndfeb magnet in Bengaluru

Report incorrect details