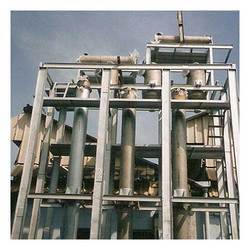

Multiple Effect Evaporators - Advanced Evaporation Technology For Water Recovery | Eco-friendly, Easy To Install, High Efficiency

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Capacity | Variable |

| Stages | Multiple |

| Pressure | 1-10 bar |

| Temperature | 50-150 °C |

| Dimensions | Customizable |

| Usage | Dairy, pharmaceuticals, food processing, chemical industries |

| Features | Eco-friendly, Easy install, Water recovery, Efficient process, High capacity, Cost-effective, Reliable operation |

Product Overview

Key Features

With dedicated and untiring support of our experts, we are manufacturing

and supplying highly reliable stock of Multiple

Effect Evaporators. Our technologically advanced plants are useful for evaporation of dilute solutions of various industries. All our evaporators are also used for concentration of slurry that is present in the solution as settled material. To

ensure quality parameters, we always follow latest norms for the development of

Multiple Effect Evaporators.

Features:

- Eco friendly

- Easy to

install - Recover

evaporated water

Further Details:

Evaporation Process Principles: Evaporation is the process used to concentrate a solution by removing the solvent (mainly water) in a purified form by the application of heat.

The evaporation process starts with a dilute solution and ends up with a more concentrated liquid. There are very few instances where the evaporated solvent is the required product.

Evaporator Process Applications

- Product concentration

- Dryer feed pre-concentration

- Solvent Volume reduction in a solution

- Water/solvent recovery

- Crystallization

- Falling Film Evaporators

- Rising Film Evaporators

- Forced Circulation Evaporators

- Thermal and Mechanical Vapor Recompression (TVR & MVR)

Forced Circulation Evaporators: Forced circulation evaporators are used if boiling of the product on the heating surfaces is to be avoided due to the fouling characteristics of the product, or to avoid crystallization. The flow velocity in the tubes must be high, and high-capacity pumps are required.

The circulating liquid is heated when it flows through the heat exchanger and then partially evaporated when the pressure is reduced in the separator, cooling the liquid to the boiling temperature corresponding to this pressure.

The heat exchanger can be arranged either horizontally or vertically depending on the specific requirements in each case.

Rising Film Evaporators: These operate on a "thermo-siphon" principle. Feed enters the bottom of the heating tubes and as it heats, steam begins to form. The ascending force of this steam produced during the boiling causes liquid and vapors to flow upwards in parallel flow. At the same time the production of vapor increases and the product is pressed as a thin film on the walls of the tubes, and the liquid rises upwards.

Multiple Effect Evaporators with Thermal Vapor Recompression (TVR): In multiple-effect evaporators the heating medium in any subsequent effect is the vapor generated in the previous effect and thereby achieves a great steam economy.

The purpose of TVR in a multiple effect evaporator is to compress the product vapor from an effect, to a higher temperature level by means of a steam ejector (TVR) to use it as the heating medium in that effect itself thereby reducing the prime steam consumption.

Company Details

Focusing on a customer-centric approach, KWS EVAPORATORS PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Water Treatment Plants in bulk from KWS EVAPORATORS PVT. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

67

Establishment

2013

Working Days

Monday To Sunday

GST NO

33AAFCK1125J1ZV

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 33AAFCK1125J1ZV

Chennai, Tamil Nadu

Accepts only Domestic inquiries

Director

Mr. Saviya Sathu

Address

NO:40/24, Welcome Colony, Opposite to CSI Church, Anna Nagar West Extn., Chennai, Tamil Nadu, 600101, India

evaporator in Chennai

Report incorrect details