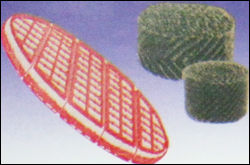

Multi Mesh Column Packing - Stainless Steel, Efficient For Distillation Towers, High Voidage, Low Bulk Density, Excellent Capillary Effect

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless steel |

| Sizes | Various |

| Density | 432 kg/cu.mtr |

| Surface Area | 1780 sq.mt./cu.mtr |

| Voidage | 94.5% |

| HETP | 12 cm |

| Pressure Drop | 0.07 mmHG |

| Features | High voidage, Low pressure drop, High surface area, Low HETP, Low bulk density, High flooding velocity, Cost effective, Improved efficiency |

| Payment Terms | Cash in Advance (CID), Cash Advance (CA) |

| Supply Ability | As Per Client Requirement |

| Certifications | ISO 9001 : 2008 |

Product Overview

Key Features

Multi Mesh Column Packing

Our company got incepted in the year 1980 as the best manufacturers of Multi Mesh Column Packing.This column packing has been considered as the most efficient packing for distillation towers that are operating at reduced pressure level. At our end, we make these packing through knitting a bunch of fine wires in to mesh that is further crimped and wounded in to a roll. Available in different column diameters, these packings use stainless steel as their construction of materials. In the market, this Multi Mesh Column Packing is known for its excellent capillary effect, low bulk density and high voids.

Salient Features:

- High voidage of Multi-Mesh column packing ensures free flow of both vapor and liquid through the packed column, resultant in low pressure drop / unit height of the packing P/Theoretical = 0.05 0.75.

- High area of surface of Multi-Mesh column packing allows an close contact between vapor and liquid, providing low values of HETP 100 to 200 mm, in production column.

- Low bulk density of Multi-Mesh column packing ensures decrease in the dead weight of the packed column. Also, it results in a lower thickness of shell.

- Multi Mesh column packing HETP (Height equivalent of theoretical plate) is less than 15 cm for the entire velocity range.

- Capillary effect / Multifilament mesh of Multi Mesh column packing wall effect is completely eliminated.

- As compared to conventional packing, flooding velocity of Multi-Mesh column packing is 2 to 2.5 times higher.

- As per the requirement, will reduce the diameter of column or will increase the throughput.

Advantages:

- Better the performance of existing columns. Also, you can upgrade the existent processes by replacing the trays or random packing with Multi-Mesh column packing. This easy change can result in higher production capacity, enhanced product quality and lower pressure by allowing the use of lower reflux ratios.

- Decreased cost of systems of new packed column. Good efficiency of Multi-Mesh column packing ensures important reductions in tower diameter & height, minimizing structural, piping, foundation, insulation and installation costs on new projects. Turn down due to capillary nature, and the Multi Mesh column packing efficiency increase with decreasing in loading, thus providing a super broad reach of operating capabilities.

Typical Applications:

Technical Details:

| Sr No. | Packing Type | Sizes | Density Kg./cu.mtr. | Sur Area Sq.mt./Cu.mtr. | Voidage % | HETP cm | PDTS mm HG |

| 1 | Multi Mesh | ALL | 432 | 1780 | 94.5 | 12 | 0.07 |

| 2 | Raschig Ring (Ceramic | 12.5mm | 804 | 410 | 64 | k | k |

| 3 | Do | 25mm | 641 | 190 | 73 | 29 | 0.53 |

| 4 | Beri Saddles (Ceramic) | 24mm | 722 | 253 | 69 | k | k |

| 5 | Intalox Saddles (Ceramic) | 12.5mm | 545 | 633 | 78 | 23 | 0.13 |

| 6 | Do | 25mm | 545 | 260 | 77.5 | k |

Company Details

Focusing on a customer-centric approach, SUMIT INDUSTRIES has a pan-India presence and caters to a huge consumer base throughout the country. Buy Wire Mesh in bulk from SUMIT INDUSTRIES at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

10

Establishment

1980

Working Days

Monday To Sunday

GST NO

27AAAPW4446Q1ZY

Payment Mode

Cash in Advance (CID), Others

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAAPW4446Q1ZY

Mumbai, Maharashtra

C.E.O.

Mr. Sumit A. Wadkar

Address

No.35, Virwani Industrial Estate, Ground Floor, W.E. Highway, Goregaon (East), Mumbai, Maharashtra, 400063, India

packed columns in Mumbai

Report incorrect details