Multi Effect Evaporation (Mee) System

Price: 300000 INR / Unit Number Number

Get Latest Price

Minimum Order Quantity :

1 Unit Number Number

Product Specifications

| Color | Gray |

| Weight | 100-5000 Kilograms (kg) |

| Product Type | Multi Effect Evaporator |

| Usage | Industrial |

| Condition | New |

| Process | Drum Evaporator |

| Application | Other, Chemical Industry |

| Material | Metal |

| Voltage | 220-415 Volt (v) |

| Warranty | 12 Months |

| Payment Terms | Cash in Advance (CID) |

| Supply Ability | 10 Per Week |

| Delivery Time | 1 Week |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Standard. |

| Main Domestic Market | All India |

Product Overview

Key Features

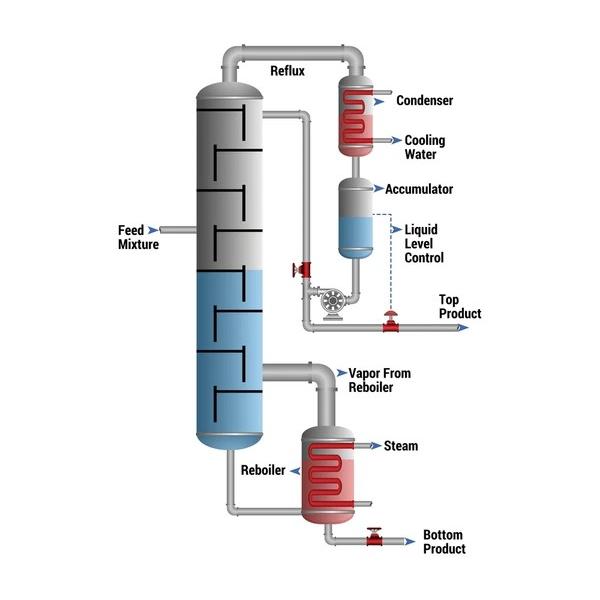

Multi Effect Evaporator (MEE) SystemAtSRP Engineering and Tech, we offer a state-of-the-art Multi Effect Evaporator (MEE) system, designed to meet the demanding needs of industries such as food and beverage, pharmaceuticals, chemicals, and more. Our MEE systems are engineered to deliver exceptional energy efficiency by maximizing heat recovery, making them an ideal solution for large-scale evaporation processes.TheMulti Effect Evaporator (MEE) systemutilizes multiple stages (or "effects") to concentrate liquids by evaporating solvents or water. Each subsequent effect operates at progressively lower pressures, using the vapor from the previous effect as the heating source, allowing the system to achieve high evaporation rates with minimal energy consumption.Our Multi Effect Evaporator (MEE) is an advanced system consist sequence or multi stages of Pre-Heater, Evaporator, Vapor Liquid Separator (VLS), and Condenser under different operating pressure. Multi Effect Evaporator (MEE) is widely used for many applications in industries to achieve evaporation and concentrate as output by using an efficient amount of heat source such as steam to evaporate low boilers such as water or solvents. Each stage of Multi Effect Evaporator (MEE) utilizes the vapor from the previous effect as a heating source, significantly reducing energy consumption and boosting overall efficiency.Pressure Range-Full Vacuum / Atm. / Under PressureOffered MOC-SS304L, SS316L, SS310, Duplex / Super Duplex Stainless Steel, Hastelloy C22 & C276, Mild Steel and any specific as per process requirement etc.Energy Efficient:By utilizing the latent heat from the vapor in successive effects, MEE systems can operate with very low specific energy consumption compared to single-effect evaporators. This makes them an ideal solution for industries aiming to reduce energy costs while maintaining high throughput.* Energy Efficient :By utilizing the latent heat from the vapor in successive effects, MEE systems can operate with very low specific energy consumption compared to single-effect evaporators. This makes them an ideal solution for industries aiming to reduce energy costs while maintaining high throughput.* Gentle Treatment of Heat-Sensitive Products :The short residence time and controlled heat input minimize the risk of degradation, making this system ideal for heat-sensitive liquids.* High Throughput :The MEE system can handle large volumes of feed material, making it a preferred choice for industries requiring high-capacity evaporation. The multi-stage process allows for efficient and effective concentration of liquids.* Versatility :Multi Effect Evaporators are versatile and can be adapted to a wide range of applications including the treatment of wastewater, concentration of fruit juices, dairy products, pharmaceuticals, and more. And also, a wide range of operating pressure.* Reduced Operational Costs :Although the initial investment in a Multi Effect Evaporator can be higher than single-effect systems, the long-term operational savings from reduced energy consumption and lower maintenance costs make it a cost-effective solution for large-scale operations.* Modular Design :Our MEE systems come with modular designs, making them scalable and customizable to meet specific requirements in terms of capacity, material properties, and energy usage.* Skid Mounted :For smaller capacities, we offer skid-mounted MEE systems that are easy to install and operate.* High Quality :Our Multi Effect Evaporator System (MEE) is designed to deliver superior performance with maximum efficiency, best manufacturing quality, durability, and reliability.

Company Details

SRP ENGINEERING AND TECH is leading Process Engineering Company in INDIA, engaged in Design, Engineering, Manufacturing, Supply & Commissioning of Industrial Process Plants and Equipment’s such as Evaporation, Distillation, Recovery, Extraction, Zero Liquid Discharge (ZLD), Drying, Mixing, Material Handling & other process equipment’s and process plants on Turnkey Basis.

SRP Engineering and Tech offers a comprehensive range of services to support industrial process plants and equipment’s, such as Basic Engineering Design, Process Simulation, and Feasibility studies.

SRP Engineering and Tech is ISO Certified company, established in 2017 by young and dynamic team of Engineers. We came in existence with latest technology and process development with expert and experienced engineered solution. We are highly technology driven, we use our skills as qualified and team work to achieve Excellency and quality Products. Every customer and his satisfaction are our asset.

Why us!

• Reliable, Advanced, Quality & Cost-Effective Solution.

• Appropriate Process Engineering.

• Basic Engineering Design, Process Simulation & Feasibility studies.

• Commitment to energy saving technology.

• Customer focused Approach.

Our Vision -

To be a world-wide leading Process Engineering solution provider company that is renowned for its innovation, advance technology and best quality products with customer satisfaction.

Industries We Serve -

• Pharmaceutical

• Chemical

• Agro-Chemical

• Food & Beverages

• Paint & Dyes

• Polymer

• Petrochemical

• Oil & Gas

• Automation

Our Turnkey Solution -

• Chemical Process Plant

• Pharmaceutical Process Plant

• Distillation System

• Solvent Recovery Plant

• Packing & Internals (Mass Transfer Products)

• Zero Liquid Discharge (ZLD)

• Multi Effect Evaporator (MEE)

• Agitated Thin Film Dryer (ATFD)

• Agitated Thin Film Evaporator (ATFE)

• Wiped Film Evaporator (WFE)

• Effluent Treatment Plant (ETP)

• Dissolved Air Floatation Plant (DAF)

Business Type

Manufacturer, Supplier

Employee Count

10

Establishment

2018

Working Days

Monday To Sunday

GST NO

27BZXPP0472J1ZM

Payment Mode

Cash in Advance (CID)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

Seller Details

GST - 27BZXPP0472J1ZM

Pune, Maharashtra

Founder

Mr Sharad Pawar

Address

915, 9th Floor, City Avenue, Near Phoenix Millennium Mall, Mumbai- Bengalore Highway, Wakad, PCMC, Pune, Maharashtra, 411057, India

multi effect evaporators in Pune

Report incorrect details