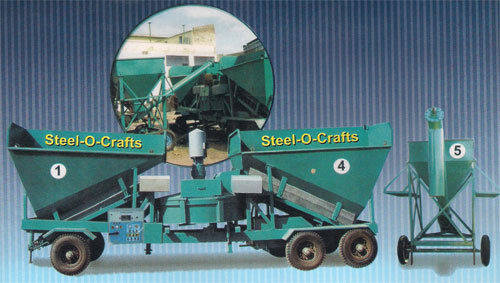

<div style="text-align: justify;"> <p style="text-align: justify;" class="MsoNormal"><font size="2" face="verdana,arial,helvetica,sans-serif"><strong>Mobile Concrete Batching Mixing Plant</strong></font></p> <p><font size="2" face="verdana,arial,helvetica,sans-serif">we manufacture a spectrum of Mobile Concrete Batching Mixing Plant. this plant is intended for high efficiency and with the help of our specialists we are on the brink of getting appreciated by our esteemed clients. our range is installed with fully automatic remote controlled systems which make the operations more convenient for the users. These plants can be mounted over the JCB and facilitates easy mobility. Our range is robust and do not require high maintenance and available in competitive prices in market. </font></p> <p style="text-align: justify;" class="MsoNormal"><font size="2" face="verdana,arial,helvetica,sans-serif"><br /></font></p><font size="2" face="verdana,arial,helvetica,sans-serif"><span style="font-weight: bold;">Salient Features</span></font><font size="2" face="verdana,arial,helvetica,sans-serif"><br /><span style="font-weight: bold;"></span></font></div><ul style="text-align: justify;"> <li><font size="2" face="verdana,arial,helvetica,sans-serif">Available in 15 m<sup>3</sup> / 20 m<sup>3</sup> / 125 m<sup>3</sup> / h - Capacity</font></li> <li><font size="2" face="verdana,arial,helvetica,sans-serif">Compact Design for easy to Transportation and Shifting by Towing Also</font></li> <li><font size="2" face="verdana,arial,helvetica,sans-serif">Loading of Aggregate / Sand Hoppers by Wheel Loader / JCB</font></li> <li><font size="2" face="verdana,arial,helvetica,sans-serif">Microprocessor Based Control Panel with integral Computerized Batch Controller accommodates Different Mix Receipes - 5</font></li> <li><font size="2" face="verdana,arial,helvetica,sans-serif">Fully Automatic Plant with Electronic Weighing of Agg. / Sand / Water / Cement</font></li> <li><font size="2" face="verdana,arial,helvetica,sans-serif">Plant can be Erected & Commissioned withing One Day</font></li> <li><font size="2" face="verdana,arial,helvetica,sans-serif">Complete Plant can be Transported in One 40 foot Trailer</font></li> <li><font size="2" face="verdana,arial,helvetica,sans-serif">Plant Only requires Electric power Supply, Water Piping / Agg. Sand Feeding</font></li> <li><font size="2" face="verdana,arial,helvetica,sans-serif">With Discharge Belt Conveyor</font></li> <li><font size="2" face="verdana,arial,helvetica,sans-serif">High Pressure Cleaner</font></li> </ul><div style="text-align: justify;"><font size="2" face="verdana,arial,helvetica,sans-serif"><span style="font-weight: bold;">Optional</span></font><font size="2" face="verdana,arial,helvetica,sans-serif"><br /><span style="font-weight: bold;"></span></font></div><ul style="text-align: justify;"> <li><font size="2" face="verdana,arial,helvetica,sans-serif">Chemical Additive System</font></li> <li><font size="2" face="verdana,arial,helvetica,sans-serif">Printout System</font></li> <li><font size="2" face="verdana,arial,helvetica,sans-serif">Cement Silo.</font></li> </ul><table border="1" cellspacing="0" cellpadding="2" style="width: 100%; text-align: left; margin-left: 0px; margin-right: 0px;"> <tbody> <tr> <td style="vertical-align: top; font-weight: bold;"><font size="2" face="verdana,arial,helvetica,sans-serif">Dimensions<br /></font></td> <td style="vertical-align: top; font-weight: bold;"><font size="2" face="verdana,arial,helvetica,sans-serif">4 Bins<br /></font></td> <td style="vertical-align: top; font-weight: bold;"><font size="2" face="verdana,arial,helvetica,sans-serif">4 Bins<br /></font></td> </tr> <tr> <td style="vertical-align: top;"><font size="2" face="verdana,arial,helvetica,sans-serif">Total Length<br /> Total Width<br /> Total Height<br /> net Weight<br /></font></td> <td style="vertical-align: top;"><font size="2" face="verdana,arial,helvetica,sans-serif">8705 mm<br /> 2135 mm<br /> 2750 mm<br /> 7 Ton<br /></font></td> <td style="vertical-align: top;"><font size="2" face="verdana,arial,helvetica,sans-serif">8705 mm<br /> 2135 mm<br /> 2750 mm<br /> 9 Ton<br /></font></td> </tr> <tr> <td style="vertical-align: top;" rowspan="1" colspan="3"><font size="2" face="verdana,arial,helvetica,sans-serif">Pan Mixer<br /></font></td> </tr> <tr> <td style="vertical-align: top;"><font size="2" face="verdana,arial,helvetica,sans-serif">Output Rate<br /> Volume<br /> Output / Mix<br /> Mixer Motor<br /></font></td> <td style="vertical-align: top;"><font size="2" face="verdana,arial,helvetica,sans-serif">12-15 m<sup>3</sup>/hr.<br /> 1200 Lt.<br /> 750 Lt.<br /> 20 HP<br /></font></td> <td style="vertical-align: top;"><font size="2" face="verdana,arial,helvetica,sans-serif">18-20 m<sup>3</sup>/hr.<br /> 1200 Lt.<br /> 750 Lt.<br /> 30 HP<br /></font></td> </tr> <tr> <td style="vertical-align: top;"><font size="2" face="verdana,arial,helvetica,sans-serif">Sand / Aggregate<br /> Hopper Cap. Each<br /> Water Pump<br /></font></td> <td style="vertical-align: top;"><font size="2" face="verdana,arial,helvetica,sans-serif">2/4 Hopper<br /> 2.5 m<sup>3</sup><br /> 2 Nos.<br /></font></td> <td style="vertical-align: top;"><font size="2" face="verdana,arial,helvetica,sans-serif">2/4 Hopper<br /> 2.5 m<sup>3</sup><br /> 2 Nos.<br /></font></td> </tr> <tr> <td style="vertical-align: top;"><font size="2" face="verdana,arial,helvetica,sans-serif">Connected Power<br /></font></td> <td style="vertical-align: top;"><font size="2" face="verdana,arial,helvetica,sans-serif">50 HP<br /></font></td> <td style="vertical-align: top;"><font size="2" face="verdana,arial,helvetica,sans-serif">60 HP<br /></font></td> </tr> </tbody> </table>