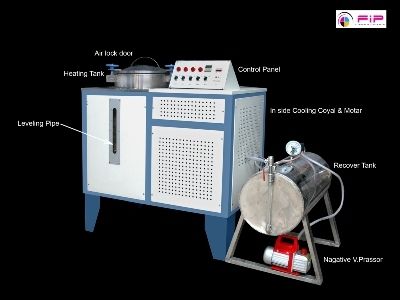

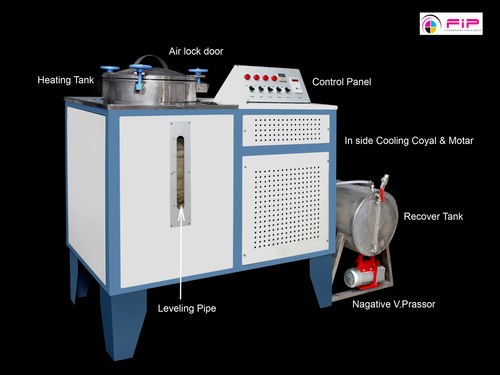

Methanol Recovery System - Stainless Steel, Automatic Operation | 99% Purity, Plc Control, Optimal Efficiency

Price: 5000000.00 INR / Pack

(5000000.00 INR + 0% GST)

Get Latest Price

MRP:

5000000.00 INR / Number

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Color | Gray |

| Product Type | Methanol Recovery System |

| General Use | Chemical Industry |

| Material | Stainless Steel |

| Automatic | Yes |

| PLC Control | Yes |

| Voltage | 220-415 Volt (v) |

| Payment Terms | Cash in Advance (CID) |

| Supply Ability | 1 Per Month |

| Delivery Time | 1 Months |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Standard. |

| Main Export Market(s) | Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia |

| Main Domestic Market | All India |

| Price Type | fixed |

| Pkg Box Length | 10.00 cm |

| Pkg Box Breadth | 10.00 cm |

| Pkg Box Height | 10.00 cm |

| Color | Gray |

| Max Quantity | 100 |

| Packsize | 1 |

| Min Quantity | 1 |

| MRP | 5000000.00 INR |

| Unit Type | Number |

| Currency | INR |

| Brand Name | ChemSepT Engineering Pvt Ltd |

| Stock Quantity | 5 |

| Mop | 1 |

| Returnable | No |

| Moq | 1 |

| Product Unit | 1 Number |

| Price | 5000000.00 INR (Approx.) |

| Minimum Ordered Packs | 1 |

| Minimum Order Quantity | 1 |

| GSTIN | 0% |

Product Overview

Key Features

Known about Methanol Recovery:

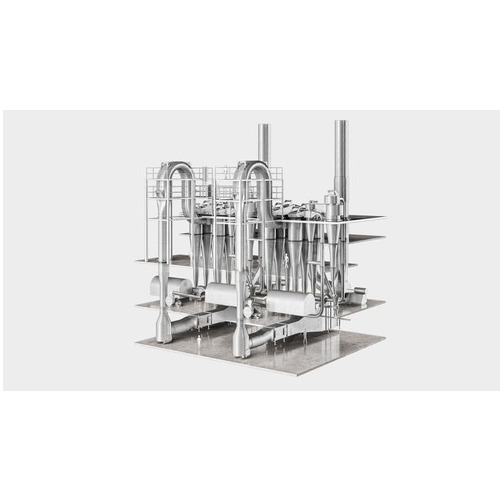

After it has been separated from the gas, the rich methanol stream (mixed with water) is led to a liquid/liquid separation tank with sufficient residence time to allow separation of hydrocarbons and methanol/water. The recovered hydrocarbons are usually pumped away for treatment outside the package. The separated methanol/water mixture is than sent to a distillation column for further processing.

From the bottom of the column purified water is collected. Water is partly vaporized in the reboiler to serve as column feed. At the top of the column, pure methanol vapoursare condensed using a heat exchanger and collected in the reflux drum. From here, part of the methanol is used as reflux for the column, and the other part is exported to the clean methanol buffer tank. By varying reboiler duty and reflux rate, the purity of the products can be adjusted. The buffer tank serves as a collection vessel from which re-injection into the main process is possible.

Benefits of Methanol Recovery Plant:

Reuse of the stripped condensate reduces plant makeup water requirements

Reduces the overall water load to the downstream treating facilities.

Recovered methanol is of sufficient purity and quantity to use as fuel for a chlorine dioxide generator.

methanol may be recovered as a salable product or stored as a liquid and burned as an auxiliary fuel.

Payment Mode : Online/Offline

Service Mode : Offline

Service Location : Pan India

Service Quality : Optimum

Company Details

ChemSept Engineering Pvt. Ltd. is a one-stop Engineering Consultancy that offers the complete range of Turn-Key Based Process & Mechanical Engineering Solutions

Business Type

Exporter, Manufacturer, Supplier, Fabricator

Employee Count

100

Establishment

2015

Working Days

Monday To Saturday

GST NO

27AAGCC2910A1ZB

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAGCC2910A1ZB

Pune, Maharashtra

Ceo

Ms. Snehal Nalawade

Address

Office No. 612, Rama Equator, Near Finolex Chowk, Morwadi, Pimpri, Pune, Maharashtra, 411018, India

alcohol distillation plant in Pune

Report incorrect details