Induction Heating Metallic Yarn Hot Stamping Foil Vacuum Metallizer Machine

Price Trend: 480000.00 - 800000.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Material | Steel |

| Processing Type | Standard |

| Condition | New |

| Technology | Diaphragm |

| Dimension(L*W*H) | 16000*7000*45000 Millimeter (mm) |

| Power Mode | Electric |

| Voltage | 380 Watt (w) |

| Power Consumption | 300 Kilowatt (kW) |

| Application | TEXTILE yarn gold silver yarn |

| Coating Type | induction heating |

| Warranty | 1 year |

| FOB Port | shanghai |

| Supply Ability | 30 Per Year |

| Delivery Time | 5 Months |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | factory standard packaging |

| Main Domestic Market | All India |

| Certifications | ISO9001 |

Product Overview

Key Features

Substrate: PET. BOPP

Application: Textile yarn: metallic yarn, gold or silver yarn wire, packaging film.

Introduction:

1. Advantage: better uniformity, extremely least amount pinhole, no sputtering, best fastness of coating layer.

2. Control system: Siemens touch screen and PLC control operation system, Siemens motor and inverter control higher accuracy AC variable frequency consistent tension winding system.

3. Vacuum system: equips big power pump group and Polycold, suitable for any environment.

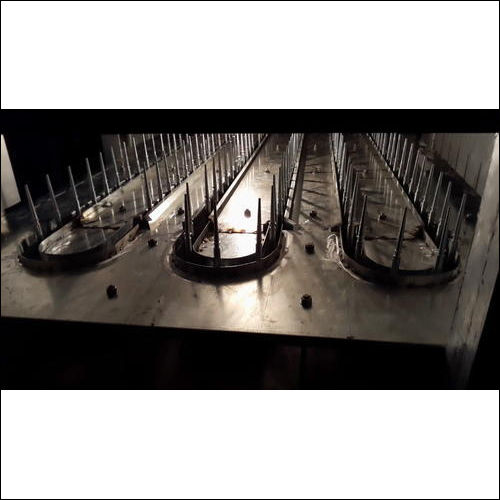

4. Theory: Induction heating evaporating source is applied to metallize aluminum on film by winding vacuum metalizing machine, put the crucible with Al ingot into the central of wire coil (not touch), connect high frequency power supply inside the wire coil, make Al ingot produce current and heat it temperature until evaporating, induction coil is made of copper pipe and filled with cooling water, in order to make film layer much uniformity, each power of crucible coil could be controlled separately.

5. Evaporating source: high frequency induction heating, graphite crucible induction heating, avoid traditional thickness, make sure least pin hole, winding speed up to 8-11m/s, totally meet market requirement.

6. High quality core parts: 1, Germany Leybold pump or Busch Pump or Aerzen Pump, 2, Imported SKF bearing 3, High quality Polycold system 4, Main and sub drum cooling system.

Company Details

Focusing on a customer-centric approach, Sichuan Sis Vacum Technology Co., Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Vacuum Equipment & System in bulk from Sichuan Sis Vacum Technology Co., Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Employee Count

50

Establishment

2008

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Chengdu, Sichuan

Manager

Mr Bright

Address

Dragon Industry Zone, Lognquanyi District. Chengdu, Sichuan, 610100, China

vacuum metalizer in Chengdu

Report incorrect details