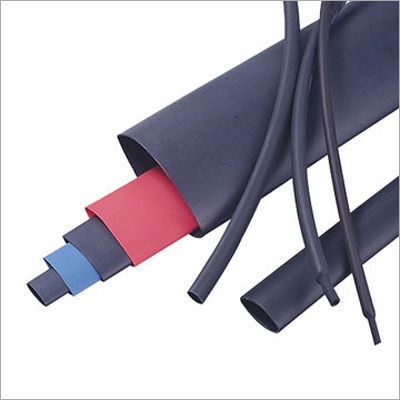

Medium & Heavy Wall Tubing

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Medium & Heavy Wall Tubing

Since establishment in this domain in 1985, we have been offering Medium & Heavy Wall Tubing to our clients. The offered tubing is suitable for insulating terminal blocks and wire joints to assure waterproofing and corrosion protection. This tubing is manufactured by our seasoned professionals using optimum quality polymers and cutting-edge techniques. To suit the diversified requirements of our clients, the provided Medium & Heavy Wall Tubing is available with us in different lengths, colors and finishes at the lowest prices.

Features of Medium & Heavy Wall Tubing :

- Unmatched versatility

- Flame and fire retardant

- Prompt and immediate shrinkage

- Flame resistivity including 2:1, 3:1, 4:1 shrink ratio

- Sturdy sealing giving better protection against moisture, water or other fluids

- Consistent operating temperature spans from -45 to ~125

- Shrinking temperature optimally requires 120

Heavy Wall Heat Shrink Tubing:

Specification:

| Test item | Test method | Typical | ||

| Operation temperature | Company standard | -55-110 | ||

| Shrink temperature | Company standard | 125 | ||

| Tensile strength | ASTM D2671 | 12MPa | ||

| Elongation | ASTM D2671 | 400% | ||

| Elongation after aging (168hrs at 150) | ASTM D2671 | 350% | ||

| Tensile strength after aging (168hrs at 150) | ASTM D2671 | 12MPa | ||

| Dielectric strength | ASTM D2671 | 15kV/mm | ||

| Volume resistivity | ASTM D257 | 1X1014cm | ||

| Copper corrosion | ASTM D2671 | No corrosion | ||

| Water absorption | ASTM D570 | 0.5% | ||

| Cold blend(-55/4hrs) | ASTM D2671 | No cracking | ||

| Size: | ||||

| Size | ID as supplied | ID after recovery | Wall thickness after recovery | Standard length |

| 9/3 | 9 | 3 | 2.6 | 1.22m/pc |

| 12/4 | 12 | 4 | 2.8 | 1.22m/pc |

| 16/5 | 16 | 5 | 3 | 1.22m/pc |

| 19/6 | 19 | 6 | 3 | 1.22m/pc |

| 22/6 | 22 | 6 | 3.2 | 1.22m/pc |

| 25/8 | 25 | 8 | 3.2 | 1.22m/pc |

| 33/8 | 33 | 8 | 3.9 | 1.22m/pc |

| 40/12 | 40 | 12 | 3.9 | 1.22m/pc |

| 45/13 | 45 | 13 | 4 | 1.22m/pc |

| 55/16 | 55 | 16 | 4 | 1.22m/pc |

| 65/19 | 65 | 19 | 4 | 1.22m/pc |

| 75/22 | 75 | 22 | 4 | 1.22m/pc |

| 85/25 | 85 | 25 | 4 | 1.22m/pc |

| 95/25 | 95 | 25 | 4 | 1.22m/pc |

| 100/30 | 100 | 30 | 4 | 1.22m/pc |

| 115/34 | 115 | 34 | 4 | 1.22m/pc |

| 130/36 | 130 | 36 | 4 | 1.22m/pc |

| 140/42 | 140 | 42 | 4 | 1.22m/pc |

| 150/50 | 150 | 50 | 4 | 1.22m/pc |

| 160/50 | 160 | 50 | 4 | 1.22m/pc |

Specification :

| Test item | Test method | Typical | ||

| Operation temperature | Company standard | -55-110 | ||

| Shrink temperature | Company standard | 120 | ||

| Tensile strength | ASTM D2671 | 12MPa | ||

| Elongation | ASTM D2671 | 400% | ||

| Elongation after aging (168hrs at 150) | ASTM D2671 | 350% | ||

| Tensile strength after aging (168hrs at 150) | ASTM D2671 | 12MPa | ||

| Dielectric strength | ASTM D2671 | 20kV/mm | ||

| Volume resistivity | ASTM D257 | 1X1014cm | ||

| Copper corrosion | ASTM D2671 | No corrosion | ||

| Water absorption | ASTM D570 | 0.5% | ||

| Cold blend(-55/4hrs) | ASTM D2671 | No cracking | ||

| Size: | ||||

| Size | ID as supplied | ID after recovery | Wall thickness after recovery | Standard length |

| 10/3 | 10 | 3 | 1.7 | 1.22m/pc |

| 12/4 | 12 | 4 | 2 | 1.22m/pc |

| 16/5 | 16 | 5 | 2.2 | 1.22m/pc |

| 19/6 | 19 | 6 | 2.2 | 1.22m/pc |

| 22/6 | 22 | 6 | 2.5 | 1.22m/pc |

| 25/8 | 25 | 8 | 2.5 | 1.22m/pc |

| 28/6 | 28 | 6 | 2.5 | 1.22m/pc |

| 33/8 | 33 | 8 | 2.5 | 1.22m/pc |

| 35/12 | 35 | 12 | 2.5 | 1.22m/pc |

| 40/12 | 40 | 12 | 2.5 | 1.22m/pc |

| 45/13 | 45 | 13 | 2.5 | 1.22m/pc |

| 55/16 | 55 | 16 | 2.7 | 1.22m/pc |

| 65/19 | 65 | 19 | 2.8 | 1.22m/pc |

| 75/22 | 75 | 22 | 3 | 1.22m/pc |

| 85/25 | 85 | 25 | 3 | 1.22m/pc |

| 95/25 | 95 | 25 | 3 | 1.22m/pc |

| 115/34 | 115 | 34 | 3 | 1.22m/pc |

| 140/42 | 140 | 42 | 3 | 1.22m/pc |

| 150/42 | 150 | 42 | 3 | 1.22m/pc |

| 160/50 | 160 | 50 | 3 | 1.22m/pc |

| 175/58 | 175 | 58 | 3 | 1.22m/pc |

| 200/65 | 200 | 65 | 3 | 1.22m/pc |

| 230/75 | 230 | 75 | 3 | 1.22m/pc |

Company Details

Focusing on a customer-centric approach, J. M. ENGINEERING CO. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Insulation Material in bulk from J. M. ENGINEERING CO. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Employee Count

10

Establishment

1985

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Mumbai, Maharashtra

Proprietor

Mr. Kamlesh K. Sheth

Address

177, Manhar Building, 3rd Floor, Lohar Chawl, Mumbai, Maharashtra, 400002, India

heavy wall tubing in Mumbai

Report incorrect details