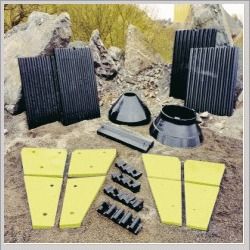

Austenitic Manganese Steel - 12% Mn, 1.2% C | High Wear Resistance, Shock Resistance, Ideal For Rock Processing Equipment

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Manganese steel |

| Dimensions | Varied |

| Hardness | High |

| Manufacturing process | Casting |

| Surface finish | As cast |

| Weight | Varies |

| Applications | Industrial |

| Features | High wear resistance, Shock resistance, Durable castings, Customizable designs, High tensile strength, Cost effective, Versatile applications |

Product Overview

Key Features

Manganese steel - a steel with a relatively large component (10-14%) of manganese; highly resistant to wear and shock.

The original austenitic manganese steel, containing about 1.2% C and 12% Mn, was invented by Sir Robert Hadfield in 1882. Many variations of the original austenitic manganese steel have been proposed, often in unexploited patents, but only a few have been adopted as significant improvements. These usually involve variations of carbon and manganese, with or without additional alloys such as chromium, nickel, molybdenum, vanadium, titanium, and bismuth.

Austenitic manganese steel is used in equipment for handling and processing earthen materials (such as rock crushers, grinding mills, dredge buckets, power shovel buckets and teeth, and pumps for handling gravel and rocks). Other applications include fragmentize hammers and grates for automobile recycling and military applications such as tank track pads.

The mechanical properties of austenitic manganese steel vary with both carbon and manganese content. As carbon is increased it becomes increasingly difficult to retain all of the carbon in solid solution, which may account for reductions in tensile strength and ductility.

Company Details

Business Type

Importer, Manufacturer, Supplier

Employee Count

50

Establishment

1986

Working Days

Monday To Sunday

GST NO

07AAACD0503G1ZD

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AAACD0503G1ZD

Delhi, Delhi

Mr Gaurav Jain

Address

D-10, Sec-4, Bawana, Delhi, Delhi, 110039, India

manganese steel castings in Delhi

Report incorrect details