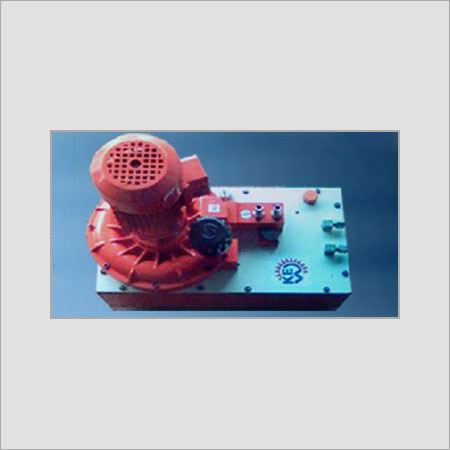

Lycra Attachment - 216 To 336 Spindles | Plc Control, Pneumatic Cradle Pressure, Compact Design, Elevated Durability, Easy Maintenance, Rugged Build

Price:

Get Latest Price

In Stock

Product Specifications

| Total Positions | 12 Nos |

| Cradle Pressure | Pneumatic |

| Ncd | Each Position |

| Cutter | Each Position |

| Motor | 5 Hp |

| Control | Plc Based |

| Drive | Fuji/Yaskawa |

| Features | Elevated Durability, Rugged Design, High Fluency, Long Service Life, Even Tension, Compact Design, Easy Maintenance, Simple Operation |

Product Overview

Key Features

Following the defined industrial standards, we are betrothed to provide a quality collection of lycra attachment for texturizing machine. This attachment is manufactured by our adept professionals using high quality basic components at our technically sound production units as per the set standards. Also, offered product is tested under the supervision of our quality controllers against set parameters of quality to ensure its flawless nature. Further, It comes with a complete set of minimum 216 spindles and maximum 336 spindles and is also equipped with accessories such as beam, cradle, end cap, pneumatic system, cutter, NCD, auto cradle lifting, PLC,drive and motor etc. Our clients can avail this lycra attachment from us in numerous designs, sizes and other specifications at marginal prices.

Features:

-

Elevated durability

-

Rugged design

-

High operational fluency

-

Long service life

| Sr.no. | particulars | Description | Remark | |

| 1 | Total position in one section | 12 nos | | |

| 2. | Cradle pressure control | Pneumatic control | Individual position | |

| 3. | NCD | Each position | | |

| 4. | cutter | Each position | | |

| 5. | motor | 5 h.p /240 spindle | Direct coupled | |

| 6 | control | PLC based | | |

| 7. | derive | Fuji/yaskawa | | |

| 8. | Section length | 1400 mm | | |

| 9. | fixing | On creel wall | | |

| 10. | Operation data | Frequency reference | Or percentage base | |

| 11. | Pneumatic cylinder | Reverse /forward | As yarn break cradle will auto lift | |

| 12. | Cylinder pressure | 3.5 bar to 4.5 bar | | |

| 13. | Jet dia | Depend on denier | Customer have to provide roto jet | |

| 14. | beam | 60x60 | | |

| 15. | Pressure regulated valve | 1 set | | |

| 16. | End cap | 75 i.d | | |

|

| EVEN PACKAGE TENSION TO CONTROL THE LYCRA PERCENTAGE , COMPACT DESIGN, EASE OF MAINTENANCE, VERY SIMPLE MAINTENANCE SCHEDULE, EASE OF OPERATE , THIS SYSTEM DID NOT DECREASE THE OPERATOR EFFICIENCY, | |||

| | ||||

| | | | | |

Commercial details

1. Complete set of minimum 216 spindle max 336 spindle

2. Accessories- beam, cradle, end cap, pneumatic system, cutter, NCD, auto cradle lifting, PLC,drive, motor,

3. Warranty 6 month from the date of erection

4. Delivery 25 days after receive confirm order along with 30 % advance

Company Details

Focusing on a customer-centric approach, SHIV TEXPRO has a pan-India presence and caters to a huge consumer base throughout the country. Buy Textile Processing Machinery in bulk from SHIV TEXPRO at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Establishment

2006

Working Days

Monday To Sunday

GST NO

24ABHFS3106M1Z5

Related Products

More Product From This seller

Seller Details

GST - 24ABHFS3106M1Z5

Surat, Gujarat

Proprietor

Mr. Ashvin Vaghasiya

Address

Plot No. 51, Road no. 3, Udhyog Nagar, Behind Kanti Lal Chunilal, Surat, Gujarat, 394210, India

Textile Processing Machinery in Surat

Report incorrect details