Liquid Nitrogen Supply Tank

Price: 10000 INR / Unit

Get Latest Price

Minimum Order Quantity :

5 Unit

In Stock

Product Specifications

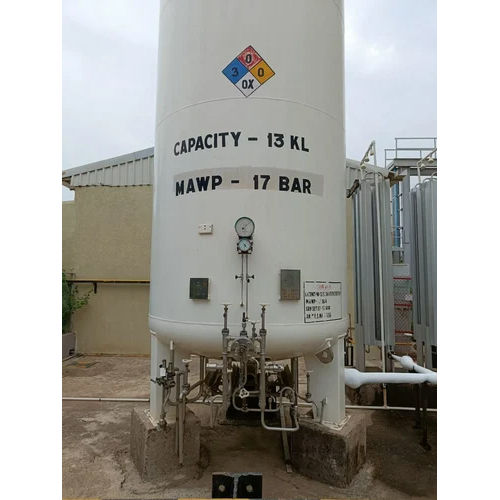

| Product Type | Liquid Nitrogen Supply Tank |

| Color | White |

| Usage | Liquid Nitrogen Storage |

| Material | Metal |

| Shape | Round |

| Application | Lab |

| Payment Terms | Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP) |

| Supply Ability | 150 Per Week |

| Delivery Time | 5 Days |

| Main Domestic Market | All India |

Product Overview

Key Features

Multi-layer Reflective Screen: 30-50 layers of alternating aluminum foil, with a reflectivity of a Y95%, significantly reducing radiative heat transfer.

High Vacuum Chamber: Vacuum depth a 2A 10a A Pa, with a free path of gas molecules reaching several meters.

Adsorbent Filler: Activated carbon or molecular sieve, continuously adsorbs residual gas.

Technical Value: This structure reduces the daily evaporation rate of liquid nitrogen containers to 0.1%.

2. Inner Tank and Outer Shell

Components, Material Selection, and Features

Inner Tank: 304 Stainless Steel/Aluminum Alloy, -196A C cryogenic resistance, intergranular corrosion resistance.

Outer Shell: 304 Stainless Steel/Aluminum Alloy. Protects against mechanical shock and maintains the integrity of the vacuum layer.

3. Neck Tube and Sealing System

Neck Tube Design: Slender structure (length-to-diameter ratio a Y 5:1) reduces heat conduction. Available in diameters from 35 to 500mm, it adapts to various scenarios.

Seal:

Polyurethane neck plug (resistant to -200A C) blocks cold air from escaping the tank opening.

II. Type Differences

1. Structural Features of Storage-Type Liquid Nitrogen Tanks

Optimized Static Insulation: Thicker insulation layer, daily evaporation rate a 0.08%

No Shockproof Design: For use in fixed locations only, suitable for long-term storage of laboratory samples.

2. Transport-Type Features

Road Transport: Enhanced liner support reduces vibration and sway.

Air Transport: Includes Adsorbent material absorbs liquid nitrogen and releases nitrogen gas, eliminating liquid nitrogen from the tank and ensuring smooth security inspection.

3. Features of Self-pressurized Liquid Nitrogen Containers

Vaporization and Boosting Module: Boosting pipe + Boosting valve (<0.1 MPa)

Dual Safety Valve Design: Dual pressure relief provided by a mechanical valve and a bursting disc

Note: Self-pressurized models are often referred to as liquid nitrogen cylinders or Dewar flasks and are used for liquid nitrogen replenishment in various locations.

III. Structural Innovations in the Safety System

1. Pressure Protection Mechanism

Pressure Balancing Valve: Automatically adjusts the internal and external pressure differential (threshold A 0.01 MPa)

Overpressure Protection: Dual safety valves activate to relieve pressure at a Y0.09 MPa

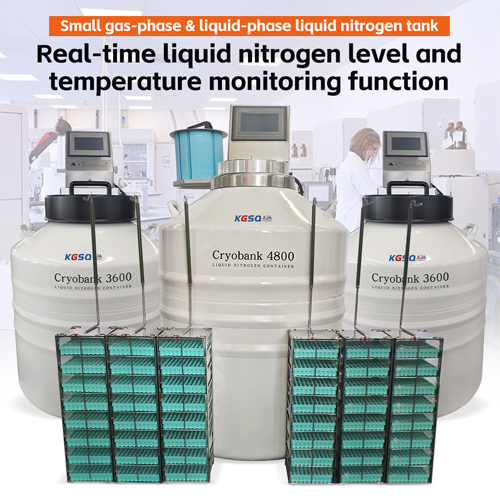

2. Intelligent Monitoring Integration

Sensor Type Monitoring Parameters Accuracy Standards

Electronic Liquid Level Gauge: Liquid Nitrogen Residual A 3%

Temperature Probe: Gas/Liquid Phase Temperature A 1A C

IV. Industry Evolution of Liquid Nitrogen Tank Structures

1. Material Upgrade Path

Traditional: Stainless Steel Housing (Heavy and Costly) a Lightweight: Aviation Aluminum Housing (30% Weight Reduction)

Adsorbent Iteration: Silica Gel a Molecular Sieve-Activated Carbon Composite (Adsorption Efficiency Doubled) 2. Intelligent Integration Trends

Predictive Maintenance: AI analyzes evaporation rate curves to provide early warning of vacuum decay.

V. Selection and Maintenance Recommendations

1. Structural Selection Strategy

Biological Sample Bank: Choose a vapor phase tank (large diameter + internal partitions, storage density a Y 2000 tubes/m2).

Industrial Site: Choose a pressurized liquid nitrogen supply tank (compatible with production line connection).

2. Maintenance Key Points for Extending Lifespan

Annual Inspection: Vacuum level (a 5 A 10a A Pa), seal elasticity (compression set a 15%).

Cleaning Standards: Wipe the neck with anhydrous ethanol; do not use metal tools to remove frost.

The intricacies of liquid nitrogen tank structural design lie in balancing insulation efficiency, safety, and practicality. Understanding its technical characteristics will facilitate informed selection and standardized operation.

Company Details

Henan Tianchi is a high-tech enterprise specializing in the R&D, production, and sales of liquid nitrogen tanks, with 20 years of industry experience. The company is certified with ISO9001, CE, and operates a modern production facility spanning 15,000 square meters. Utilizing automated welding and spinning processes, we ensure superior product quality.

Our main product lines include aluminum alloy and stainless steel liquid nitrogen tanks, widely used in medical, scientific research, animal husbandry, and industrial applications. Each unit undergoes 100% liquid nitrogen performance testing to guarantee optimal thermal insulation and reliability. We offer 24-hour express shipping services, and our products are exported to over 40 countries and regions, including the United States, Brazil, and Thailand.

Adhering to the quality philosophy of "Continuous Improvement, Striving for Excellence," we are committed to providing global customers with high-quality products and services, making us your trusted partner for cryogenic storage solutions.

;

Contact: +86 7

Business Type

Exporter, Manufacturer, Supplier

Establishment

2010

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhengzhou, Henan

Manager

Mrs. Jing Zeng

Address

Jinshui District, Zheng Hua, Road No. 100, Zhengzhou, Henan, 450000, China

liquid nitrogen tank in Zhengzhou

Report incorrect details