Internal Heat Reactivated Air Dryer

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Internal Heat Reactivated Air Dryer

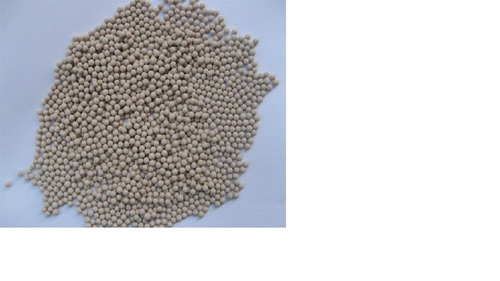

Heat Reactivated dryer are used when one needs compressed air of very low dew point of (-) 60C or 80C. In this design, the desiccant is regenerated at higher temperature, along with small quantity of dry air Purge. Due to purging with dry air and thermal regeneration, residual moisture loading on desiccant becomes low and this gives very low dew points.

Capacity:

Air Capacity: 5 to 5000 Nm3/Hr

Dew Point : Up to (-) 40C to (-) 80C

Operating Pressure: 5 to 35 Kg/cm2g

Operating Principle:

The drying unit has 2 vessels filled with Activated Alumina or Molecular sieves desiccant. One vessel remains in drying cycle for 4 hours, while other vessel is simultaneously regenerates at atmospheric pressure. Around 3% flow of dryer capacity is used as purge for regeneration. Electrical heaters are provided in a central finned stainless steel pipe in both drying vessels. Heating cycle is for 2 hours and in this time hot purge air increases desiccant temperature to around 100 degree c. At this temperature regeneration is complete (due to dry air purge). Dew point achieved is around 40 degree c. If still lower dew point is required, air purging rate is slightly increased to 5% for 60 degree C and to 7.5% for 80 degree C DEW point requirements.

Filters:

A pre-filter with automatics drain valve is provided to remove any physical moisture from Compressed air before entering air Dryer. A Micron filter is also provided in dryer outlet to arrest any desiccant dust particles, up to 1 micron size. Thus you get absolutely Clean & dry compressed air.

Features:

A fully automatics unit requiring no attention of the operator. Heaters switch ON/Off and all valves operate automatically.

Pressure is equalized to line pressure before changeover of drying vessels. This prevents pressure and flow surge and desiccant dusting.

Low pressure air requirement in compression to heatless type air dryer.

Desiccant life is around 5 year.

Internal heaters provided maximum heat transfer efficiency resulting in lower power requirements.

Counter current heated dry purge air provides maximum removal of moisture with minimum gas purge loss.

Heaters are not in physical contact with the desiccant resulting in long life or desiccant.

Company Details

Focusing on a customer-centric approach, AVS ENGINEERING COMPANY has a pan-India presence and caters to a huge consumer base throughout the country. Buy Air Dryers in bulk from AVS ENGINEERING COMPANY at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

25

Establishment

2010

Working Days

Monday To Sunday

GST NO

24AZYPS9420M1ZD

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AZYPS9420M1ZD

Vadodara, Gujarat

Proprietor

Mr Harendra Sharma

Address

SF-1, 22, Gyankunj Society, Opp. M.S.Co.Bank, Abhilasha Char Rasta, New Sama Road, Vadodara, Gujarat, 390024, India

desiccant air dryers in Vadodara

Report incorrect details