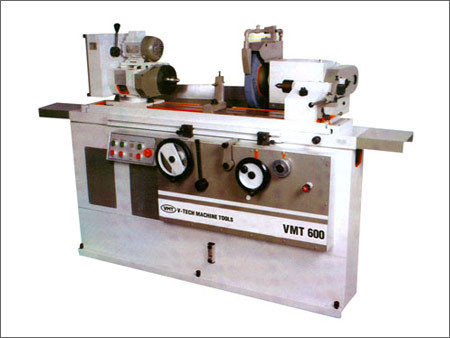

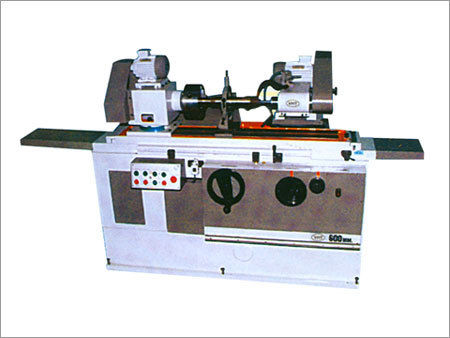

Internal Grinding Machine (Hyd.)

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Cast Iron |

| Dimensions | Variable |

| Spindle Material | Alloy Steel |

| Bearings | Angular Contact |

| Power | Variable |

| Coolant Capacity | 90 Liters |

| Voltage | 400/440V Ac |

| Features | High Rigidity, Precise Grinding, Hydraulic System, Long Life, Easy Operation, Efficient Cooling, Angular Grinding, High Accuracy |

Product Overview

Key Features

Base & Guide Ways

The

base is made of close grained and heavily ribbed casting for high

rigidity. The hand scraped V-Flat table guide wasy with continuous

lubrication. Longitudinal hand travel of the table is by rack and

pinion Gear box arrangemetn and automatic travel by hydraulic mechanism.

Hydraulic System

It consist of hydraulic Pump, Valves, Livers, Piping etc. and all conveniently housed in the base

Wheel Head

The

wheel head spindle is made of case hardened Nickel chrome alloy steel

grounded and microfinished and runs in adjustable while metal bush

bearings to achieve high accuracy and long life. Drive to the wheel

head is transmitted by two 'V' belts.

Work Head

Workhead

spindle is made of case hardened Nickel chrome alloy steel and runs in

angular contact bearing. The drive to the workhead is uitl for

stationery and live spindle grinding. The workhead can be swivelled for

angular grindings.

Tail Stock

The hardned and grounded tall staock spindle is adjustable and spring loaded.

Internal Grinding Head (Optional)

The unit

with its independent drive motor is hinged on the wheel head and can be

quickly lowered into grinding position easily. The internal Grinding

Spindle runs in two precision matchpair angular contact bearings. The

drive to the spindle is transmitted by Flat belt.

Coolant

Generous coolant supply is provided with electrical pump fitted on separate tank is of 90 Litrs approx.

Electricals

The

Machine is supplied with all electrical suitable for 400/440 V AC 50

Cycles. The motors are of reputed make. The electrical panel is mounted

on one side of the machine, push button station is located at easy

reach to the operator.

General Specifications

| Model | VMT 130/450 | VMT 130/600 |

| Centre Height | 130 | 130mm |

| Admit between centre | 450 | 600mm |

| Max. work diameter ground | 100 | 100mm |

| Table speed Min.-Max. | 300-400 mm per min. | 300-4000 MM per min. |

| Max. swivel of table | 7o | 7o |

Work Head & Tail Stock

| Speed of work head spindle | 80/150/270 RPM | 80/150/270 RPM |

| Morse taper in work head | MT-3 | MT-3 |

| Swivel of work head | +- 45o | +- 45o |

| Morse taper in tall stock | MT-3 | MT-3 |

Wheel Head:

| Grinding wheel dia. | 300 mm | 300 mm |

| Grinding wheel width | 25 mm | 25 mm |

| Grinding wheel Bore | 76.20 mm | 76.20 mm |

| Speed of grinding wheel | 2000 RPM | 2000 RPM |

Internal Grinder Attachment Optional

| Grinding Spindle Dia. | 60 mm O.D. |

| Max. Quill leangth | 81 mm |

| Quill dia. | 15 mm |

| Min. & Max. Dia. of hole grinding | 16-100 mm |

| Spindle speed | 18000 RPM |

Electric Motors

| Model | VMT 100/350 | VMT 130/450 | VMT 130/600 | VMT 150/800 | VMT 150/1000 |

| Wheel Head | 1.5 HP / 1440 RPM | 2 HP 1440 RPM | 2 HP 1440 RPM | 3 HP 1440 RPM | 3 HP 1440 RPM |

| Work Head | 0.5 HP / 1440 RPM | 0.5 HP 1440 RPM | 0.5 HP 1440 RPM | 0.5 HP 1440 RPM | 0.5 HP 1440 RPM |

| Hydarulic Pump | 1 HP / 1440 RPM | 1 HP 1440 RPM | 1 HP 1440 RPM | 1 HP 1440 RPM | 1 HP 1440 RPM |

| Coolant Pump | 0.15 HP / 2800 RPM | 0.15 HP 2800 RPM | 0.15 HP 2800 RPM | 0.15 HP 2800 RPM | 0.15 HP 2800 RPM |

| Internal Grinding attachment | 0.5 HP / 2800 RPM | 0.5 HP 2800 RPM | 0.5 HP 2800 RPM | 0.5 HP 2800 RPM | 0.5 HP 2800 |

Standard Equipment

With all electricals i.e. motors electrical panel,

pump, fitted on the machine, V-belt, coolant tank with piiping,

Grinding wheel with flange and 2 dead centres.

Extra Accessories

| Internal grinding attachment (60 OD spindle) | Two point steady rest | Wheel balancing arbour |

| True chuck flange | Three point steady rest | Wheel balancing stand. |

Company Details

Focusing on a customer-centric approach, Shree Vishwakarma Engineering Works has a pan-India presence and caters to a huge consumer base throughout the country. Buy Grinding & Milling Machinery in bulk from Shree Vishwakarma Engineering Works at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

22

Establishment

2003

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Wadhwan, Gujarat

Proprietor

Mr. Ashwin Rathod

Address

Plot No. 2409, Phase-IV, S.O. Industrial Compound, GIDC, Wadhwan, Gujarat, 363035, India

internal grinding machine in Wadhwan

Report incorrect details