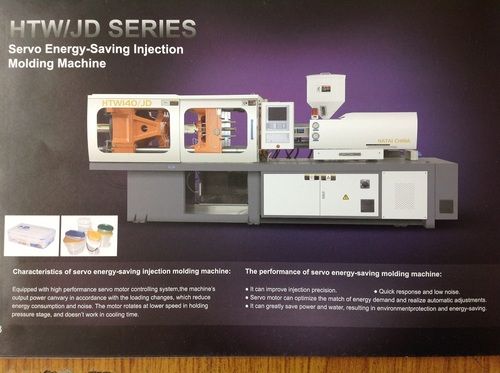

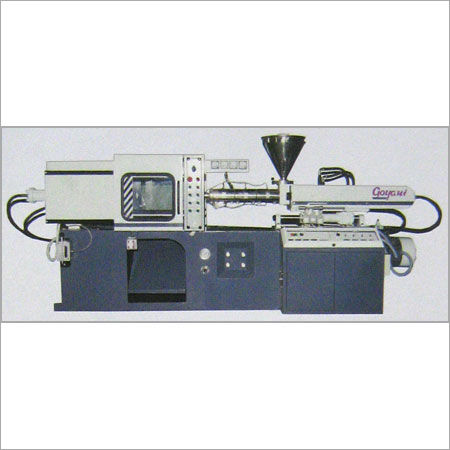

Techno Injection Moulding Machine - Plastic, Variable Mold Size, Variable Clamping Force | Automation Ready, Durable Design, Precise Molding, High Speed, Versatile Use

Price:

Get Latest Price

In Stock

Product Specifications

| Clamping Force | 100-500kN |

| Injection Pressure | 150-200 MPa |

| Injection Speed | Variable |

| Shot Size | 50-200g |

| Power Consumption | 15-30kW |

| Dimensions (LxWxH) | 3000x1500x1800mm |

| Usage | Plastic Part Production |

| Material | Steel/Aluminum |

| Weight | 2000-5000kg |

| Safety Standards | CE Compliant |

| Features | High Output, Precise Molding, Durable Design, Easy Operation, Efficient Process |

Product Overview

Key Features

Injection molding machines can fasten the molds in either a horizontal or vertical position. The majority of machines are horizontally oriented, but vertical machines are used in some niche applications such as insert molding, allowing the machine to take advantage of gravity. Some vertical machines also don't require the mold to be fastened. There are many ways to fasten the tools to the platens, the most common being manual clamps (both halves are bolted to the platens); however hydraulic clamps (chocks are used to hold the tool in place) and magnetic clamps are also used. The magnetic and hydraulic clamps are used where fast tool changes are required.

The person designing the mold chooses whether the mold uses a cold runner system or a hot runner system to carry the plastic from the injection unit to the cavities. A cold runner is a simple channel carved into the mold. The plastic that fills the cold runner cools as the part cools and is then ejected with the part as a sprue. A hot runner system is more complicated, often using cartridge heaters to keep the plastic in the runners hot as the part cools. After the part is ejected, the plastic remaining in a hot runner is injected into the next part.

Company Details

Focusing on a customer-centric approach, TECHNO PLAST has a pan-India presence and caters to a huge consumer base throughout the country. Buy Injection Moulding Machine in bulk from TECHNO PLAST at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

10

Establishment

2003

GST NO

27AANPN7975J1ZS

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AANPN7975J1ZS

Dombivli, Maharashtra

Design Manager

Mr. Manohar J. Jadhav

Address

OFFICE NO. 102-A, CITY MALL, MIDC, NEAR PENDHARKAR COLLEGE, Dombivli, Maharashtra, 421203, India

plastic injection moulding machine in Dombivli

Report incorrect details