Hydrotreating Catalyst For Naphtha Unit

Price:

Get Latest Price

In Stock

Product Specifications

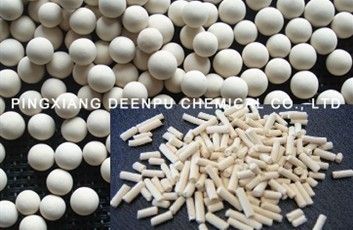

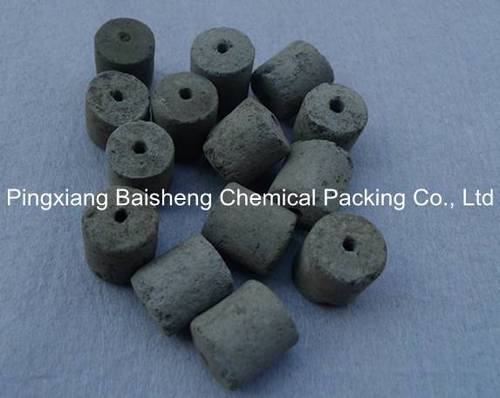

| Catalyst item No | BSCH-II |

| Active metal | Mo-Co |

| Shape | Spherical |

| Diameter | 1.5-2.5 mm |

| Pore volume | ≥0.40 mL/g |

| Surface area | ≥200 m²/g |

| Crushing strength | ≥40 N/pcs |

| Bulk density | 0.68-0.78 g/cm³ |

| Features | High activity, Long life, Improved yield, Reduced costs, Sulfur removal, Enhanced quality, Stable performance, Easy handling |

Product Overview

Key Features

Catalyst item No : BSCH-II

Active metal : Mo-Co

Shape : Spherical

Diameter, mm : 1.5 2..5

Pore volume, mL.g-1 : a R0.40

Surface area, m2.g-1 : a R200

Side rushing strength, N.pcs-1 : a R40

Bulk density, g.cm-3 : 0.68 0.78

Company Details

Focusing on a customer-centric approach, Pingxiang Baisheng Chemical Packing Co. Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Industrial Chemicals in bulk from Pingxiang Baisheng Chemical Packing Co. Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Establishment

2011

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Pingxiang, Jiangxi

Ms. Ella Liu

Address

Ceramic Industry Park, Pingxiang, Jiangxi, 337000, China

catalysts in Pingxiang

Report incorrect details